- 12 -

MAINTENANCE (con’t)

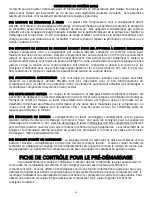

MAINTENANCE SCHEDULE

Recommendation Daily

Weekly

Monthly

Quarterly

Check Oil Level

X

Drain Moisture from Tank(s)

X

Inspect Air Filter(s)

X

Check for Unusual Noise or Vibration

X

Inspect Belt Guard

X

Check for Air or Oil Leaks

X

Clean Exterior of Air Compressor

X

Check Condition of Vibration Pads

X

Tighten/Retorque Bolts

X

Check Belt Tension

X

Check Operation of Safety Valve

X

Change Compressor Oil

X

Clean/Change Air Filter

X

Perform Pump Up Time Test

X

Check Operation of System Controls

X

Check Air Tanks for Dents/Leaks

X

TORQUE CHART (INCH/LB)

Pump Type

Direct Drive

K12 K17 K18 K24 K28 K30

Head

Bolts

96

243 243 243 243 347 347

Cylinder

Bolts

120

182 182 182 182 330 330

Bearing-Carrier

Bolts

N/A

130 130 130 130 130 130

Connecting-Rod

Bolts

N/A

121.5 121.5 121.5 121.5 121.5 173.6

Flywheel

N/A

243 382 382 382 477 477

Determine pump type using suffix of Model number (Example: 4090HK17 uses K17 pump)

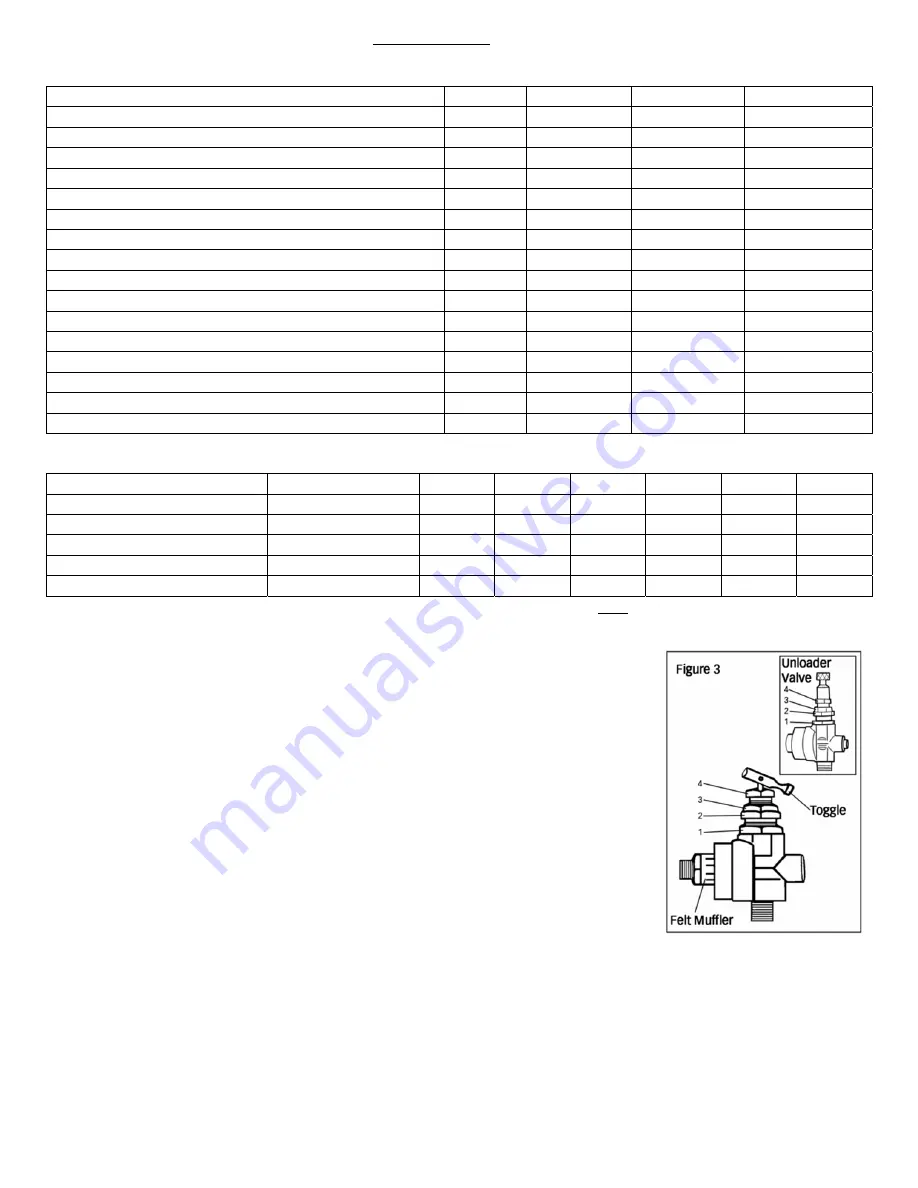

PILOT VALVE ADJUSTMENT

RESETTING DIFFERENTIAL (2)

Make sure the top toggle lever is positioned as shown. (See Figure 3).

Loosen locknut (1) by turning counterclockwise several full turns. Gently turn

differential setting (2) clockwise only until the internal rod makes contact with

the steel ball inside. After making contact, turn differential (2) counterclockwise

1/4 turn. Secure position by tightening locknut (1) and proceed to top end

setting.

TOP-END SETTING (4)

Loosen locknut (3) by turning counterclockwise several full turns. (4) is

the top end setting. Turning (4) clockwise will increase the top end pressure

setting. Turning counterclockwise will decrease the top end pressure setting.

Begin at a low setting by turning counterclockwise one full turn. Proceed to

fine tuning instructions.

FINE-TUNING INSTRUCTIONS

Start engine/motor and observe tank pressure gauge. As tank pressure approaches 100-130 P.S.I.G.,

the pilot valve should begin unloading at felt muffler and cause gas engine to slow down to idle speed. If

pilot valve does not unload as tank pressure approaches 130 P.S.I.G., slowly turn top end setting (4)

counterclockwise until pilot starts to unload prematurely (at 100 P.S.I.G.), turn top end setting (4) clockwise

in 1/4 turn increments, tap down on the internal rod at toggle attachment and repeat until desired top end

setting is reached. If pilot valve begins to rifle (sputter), fine tune differential setting (2) 1/16 turn in either

direction until rifling stops. After fine tuning, secure setting by turning locknuts (1 & 3) clockwise until tight.

Hold setting (2 & 4) in place while turning locknuts to secure.

Summary of Contents for FC2002

Page 46: ... 46 ...

Page 48: ... 48 ...