POK SAS - ZI Les Guignons - 10400 Nogent-sur-Seine - FRANCE

Tel : +33 (0)3 25 39 84 78 - Fax : +33 (0)3 25 39 84 90 - Email : [email protected] - Web : www.pok.fr

13

MOP_LAM_01289_EN R

ev

.A - 18/08/2014 - Cop

yright© POK S

A

S - Illustr

ations are only informativ

e

Maintenance

- Check the ring turn freely

- Reassemble the spring mark 32 and the ball mark 33 in the index knob mark 31, then glue

(Locite 243) and screw all parts on the head ring mark 34 until a slight contact with bore cover

mark 22 and untight on a 1/8 revolution.

• The spinning teeth is broken or doesn’t turn

- Remove 3 screws mark 37

- Remove cone-shaped piece mark 36 and spinning teeth mark 35

- Clean contact aeras between spinning teeth, head ring mark 34 and cone-shaped piece mark 36.

- If some teeth are missing or damaged, replace spinning teeth mark 35

- Reassemble the spinning teeth mark 35 and cone-shaped piece mark 36 without grease.

- Glue (Locite 243) and tight 3 screws mark 37

• The flow pattern ring doesn’t turn

- Remove the flow pattern ring as detailed above

- Remove the flow rate index knob mark 30 (pay attention to the spring mark 32 and the ball

mark 33)

- Remove the flow rate ring mark 29

- Replace gasket mark 23

- Clean and grease (Locite 8106) grooves and contact aeras of parts mark 22, 29 and 34

- Insert spring mark 32 and ball mark 33 and reassemble flow rate ring mark 29

- Glue (Locite 243) and screw flow rate index mark 30 until a slight contact with bore mark 24

and untight on a 1/4 revolution.

- Ensure that the flow rate ring turns freely

- Reassemble the flow pattern ring as detailed above

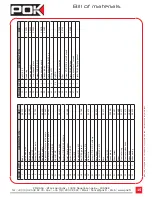

• Spare parts

Some parts such as gaskets are likely to be changed more or less often depending on the frequency of use,

conditions of use or storage.

Please contact our sales department for the prices and after sales conditions.

Refer to the schedule in this document to identify the replacement parts.

• Storage conditions

Store the equipment in a clean environment, mud, sand or other element could impede operation of the

equipment, and in rare cases damage it.

• Cleaning

It is recommended to clean the nozzle with clean water inside and outside after each use (manoeuvres have

to be carried under pressure).

It is recommended to dis-assemble the nozzle once a year if the nozzle is used continuously with salt or

brackish water. Clean and dry all components, gaskets, O rings and grease them as per POK Procedure

provided with the spare parts kit available on order. This service can be provided by our workshop, please

contact us for pricing.