L35 Lubricator

IS-L35

Installation

1. The lubricator should be installed with reasonable

accessibility for service whenever possible – repair service

kits are available. Keep pipe or tubing lengths to a minimum

with inside clean and free of dirt and chips. Pipe joint

compound should be used sparingly and applied only to

the male pipe – never into the female port. Do not use

PTFE tape to seal pipe joints – pieces have a tendency to

break off and lodge inside the unit, possibly causing

malfunction. Also, new pipe or hose should be installed

between the filter and equipment being protected.

2. The upstream pipe work must be clear of accumulated

dirt and liquids.

3. Select a lubricator location as close as possible to the

equipment being protected and upstream of any pressure

regulator.

4. Install lubricator so that air flows in the direction of arrow

on body.

5. Install lubricator vertically with bowl drain mechanism at

the bottom.

Lightly grease with provided lubricant.

Inspect for nicks, scratches, and surface imperfections.

If present, reduced service life is probable and future

replacement should be planned.

Clean with lint-free cloth.

Operation and Service

1. Filling — The inlet pressure of the lubricator must be turned

off and depressurized before the Fill Plug is removed. Turn

counterclockwise to remove. Fill to within 1/4" from top of

bowl or to top of the sight glass on the bowl.

Suggested lubricant: F442

Petroleum based oil of 100 to 200 SSU viscosity at 100°F

and an aniline point greater than 200°F. (Mobil DTE24

and Sun Company Sunvis 932 are good examples). Do

not use oils with adhesives, compound oils containing

solvents, graphite, detergents or synthetic oils.

2. Replace the Fill Plug (by turning clockwise) and seat

firmly. Excessive torque is not required. Turn on air supply,

if leakage occurs,

DO NOT OPERATE

— conduct repairs

again. The lubricator is now ready for setting.

3. Oil delivery adjustment — To adjust oil delivery, turn

Adjustment Knob on top of the lubricator.

Leaner — Clockwise

Richer — Counterclockwise

By counting the number of drops per minute in the Sight

Dome, you can adjust to your requirements. Generally,

one drop per minute downstream for every

10 - 15 SCFM flow is satisfactory. 25 drops per minute

equals one (1) ounce per hour - volume of oil passing

through the Sight Dome.

NOTE:

This is a constant density type lubricator which

delivers a constant ratio of oil air flow. Therefore, if air

flow increases or decreases, oil delivery will be

adjusted propor tionately. ONLY IF A DIFFERENT

RATIO IS DESIRED SHOULD YOUR ADJUSTMENT KNOB

SETTING BE CHANGED AFTER YOUR INITIAL SETTING.

4. Cleaning — Erratic lubricator operation or loss of lubrication

is almost always due to dirt (rust, pipe tape, etc.) in the

needle valve or venturi area. To clean, shut off and vent all

air line pressure to the unit being cleaned. In most cases

cleaning is needed only in the oil metering area. Pull off

Adjusting Knob and remove Sight Dome Assembly. Make

sure hole in Body Seat and Drip Spout is clear. Remove

Bowl. Clean parts with soapy water or denatured alcohol

but do not use denatured alcohol on plastic bowl,

sight dome or sight gauge

. If using compressed air to

blow dry, be sure to wear appropriate eye protection.

5. After servicing, apply system pressure and check for air

leaks. If leakage occurs,

Do Not Operate

— conduct

servicing again.

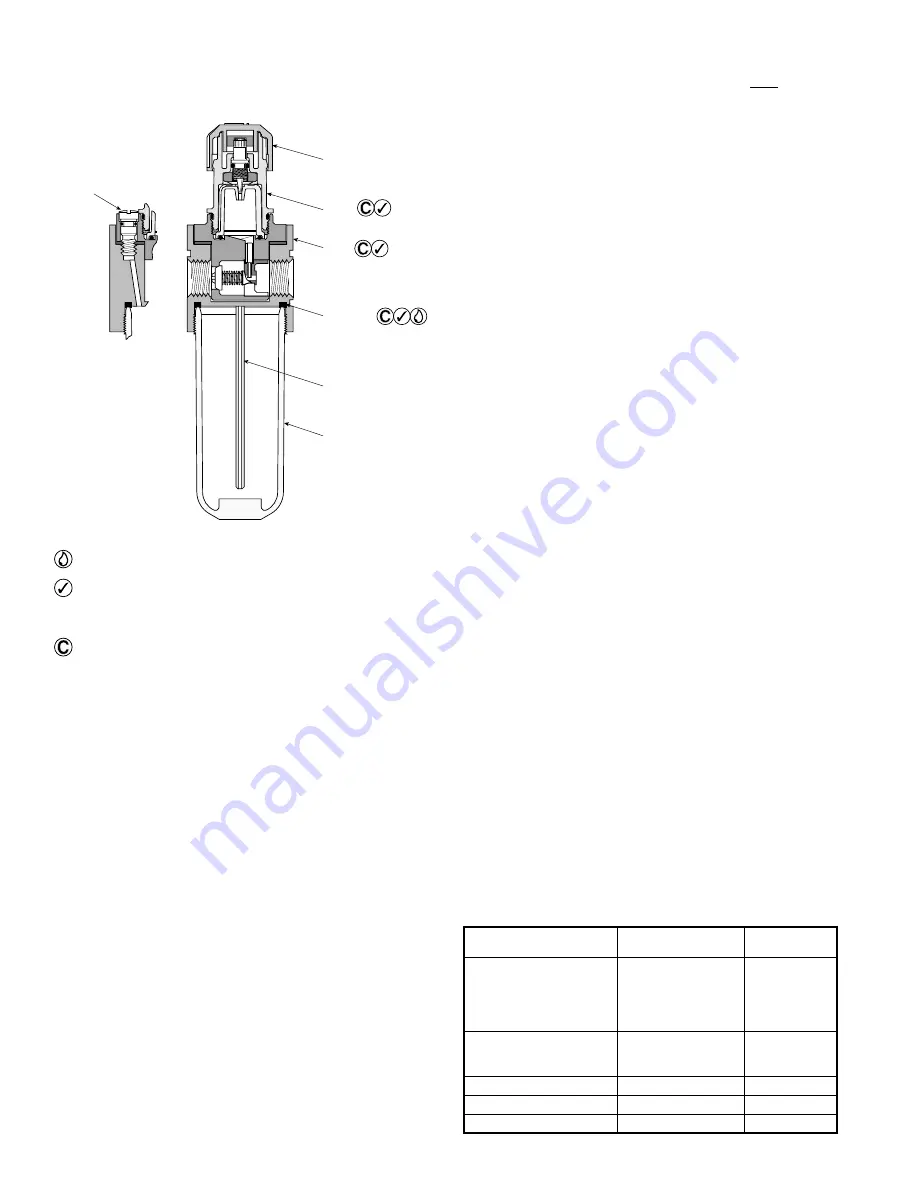

Dip Tube

Bowl Seal

Bowl

(Hand Tighten)

Body

Adjustment

Knob

Fill Plug

Sight

Dome

Kits Available

Product

Bowl

Description

Number

Type

Bowl

Polyurethane

BKL35A

A

Zinc

BKF35D

D

Zinc with Wrap

Around Sight Gauge

BKL35W

W

Repair Kit

Tamper-resistant

RKL100

A, D, W

Sight Dome Repair Kit

Adjusting Knob

L100-0726P

—

Dip Tube

L30-0741

—

Bowl Seal

GSK-504Z101

A, D, W