01-999-2521

Page 4

Controls

Rocker-type control switches are used to select the operating mode

of the cooler. These switches control fan speed (FAN-HIGH/OFF/

LOW) and the pump operation (COOL-ON/OFF). To eliminate a

rush of warm air when starting the cooler, be sure to turn the pump

(COOL) on for a few minutes before turning on the blower motor

(FAN) in low or high speed.

Maintenance Schedule

Regular maintenance and periodic inspection is a key to long and

successful service of your Patio Pal Cooler. The cooler should

be serviced at least once a year, or more often if required. For

maximum efficiency, longer life and appearance, every two months

during operation, the cooler should be inspected and cleaned.

Drain water from the unit every 8-10 hours of operation to minimize

scaling build up.

Note: Do Not Undercoat the Water Reservoir

Your cooler's water reservoir is finished with our Peblar XT®

appliance-type finish. It is so hard that asphalt-type cooler

undercoating will not stick to it. Undercoating will break free,

clogging the pump and water distributor.

NOTE:

Do not use cooler cleaners, cooler treatments or

other chemical additives in this evaporative cooler. Use of

any additives or water treatment will void your warranty and

impair the life of the cooler.

Before starting any maintenance operation, read thoroughly

all operating and maintenance instructions and observe all

cautions and warnings.

CAUTION: Disconnect all electrical power to the cooler by

removing plug from receptacle before attempting to install,

open, or service your cooler.

Even while routinely inspecting or servicing the inside, the

cooler can be accidentally started. Keep all personnel away

from the cooler and electrical supply when you are working

on it. Before servicing or cleaning unit, switch “COOL” and

“FAN” to the OFF position and remove power cord from

receptacle.

Cleaning

CAUTION: Never wash your cooler cabinet with a

garden hose; water may harm motor and pump. Motors

damaged by water are NOT covered under warranty.

All foreign materials, scale, salt deposits, lime, etc. can and

should be removed from bottom pan and other components.

Your cooler's long lasting finish can be brought to like-new

condition by using warm water and a soft cloth.

NOTE:

Avoid using scouring pads, steel wool or wire

brushes, as these will damage the finish and encourage

corrosion.

Patio Pal is equipped with two removable cutting boards integrated

in the handles. The cutting boards are dishwasher safe or may be

cleaned with water, dish soap, and a soft cloth.

Cleaning the ice chest

The ice chest is lined with a high strength plastic liner that can last

for many years if properly maintained. Use the following procedure

to clean the ice chest:

1. Unplug the unit from the GFCI power outlet.

2. Move cooler to the area appropriate to dump water.

3. Remove the pad frame from the back of the unit.

4. Place the end of the ice chest drain tube outside the of the drain

pan.

Do not drain water mixed with cleaning agents into the

drain pan.

5. Remove the rubber drain stop.

6. Scrub the liner with water, dish soap, and a soft cloth until clean.

7. Rinse the liner until all cleaning agents are gone.

8. Dry the all surfaces of the liner.

9. Place the ice chest drain tube back inside the cabinet and

reinstall the pad frame.

Maintenance & Inspection

CAUTION: Disconnect all electrical power to the cooler

by removing the plug from the receptacle before

attempting to install, open, or service your cooler.

IMPORTANT: Before operating cooler at beginning of

each cooling season, turn cooler motor and pump motor

shafts by hand to make sure they turn freely. Failure to

do so may result in burning out motor.

Periodic inspection of your cooler will enhance the chance for long,

trouble-free service life. For maximum efficiency, every two months

during operation, or any time the cooler is opened, the cooler

should be inspected. Some suggested items:

• Check for leaks from pad frames, cabinet, etc.

• Are there any dry spots on the media when cooler is in operation?

• Are bolts, nuts and set screws snug?

• Is bearing making unusual noises?

• Does the blower wheel turn freely?

• Is float level set correctly?

• Is water in the bottom pan clean?

• Belt condition / tension / alignment?

Adjust Belt Tension

CAUTION: Disconnect all electrical power to the cooler

and insure that belt is not rotating before adjusting belt

tension.

Each time you inspect your cooler, be sure to check belt tension

on motor/blower assembly. Check belt condition and replace it if

frays or cracks appear. Check alignment of blower pulley with motor

pulley (

see page 3

).

Cleaning Water Pump & Hose

CAUTION: Do not allow pump to fall over and become

submerged; water will damage pump motor.

Clean water pump and hose assembly as follows:

1. Unplug pump cord, remove mounting bracket screw and

remove pump from cooler. Shake gently to remove water.

CONTROL SWITCHES

01-999-2521

Page 5

2. To prevent breakage, carefully release

and remove impeller base plate from

the pump body.

3. Using a mild detergent solution and

clean cloth, clean deposits from pump

screen, around impeller and base plate.

4. Spin impeller to dislodge any foreign

material.

5. Remove any foreign material in the

adapter between the pump and hose,

or between the hose and the water

distributor assembly.

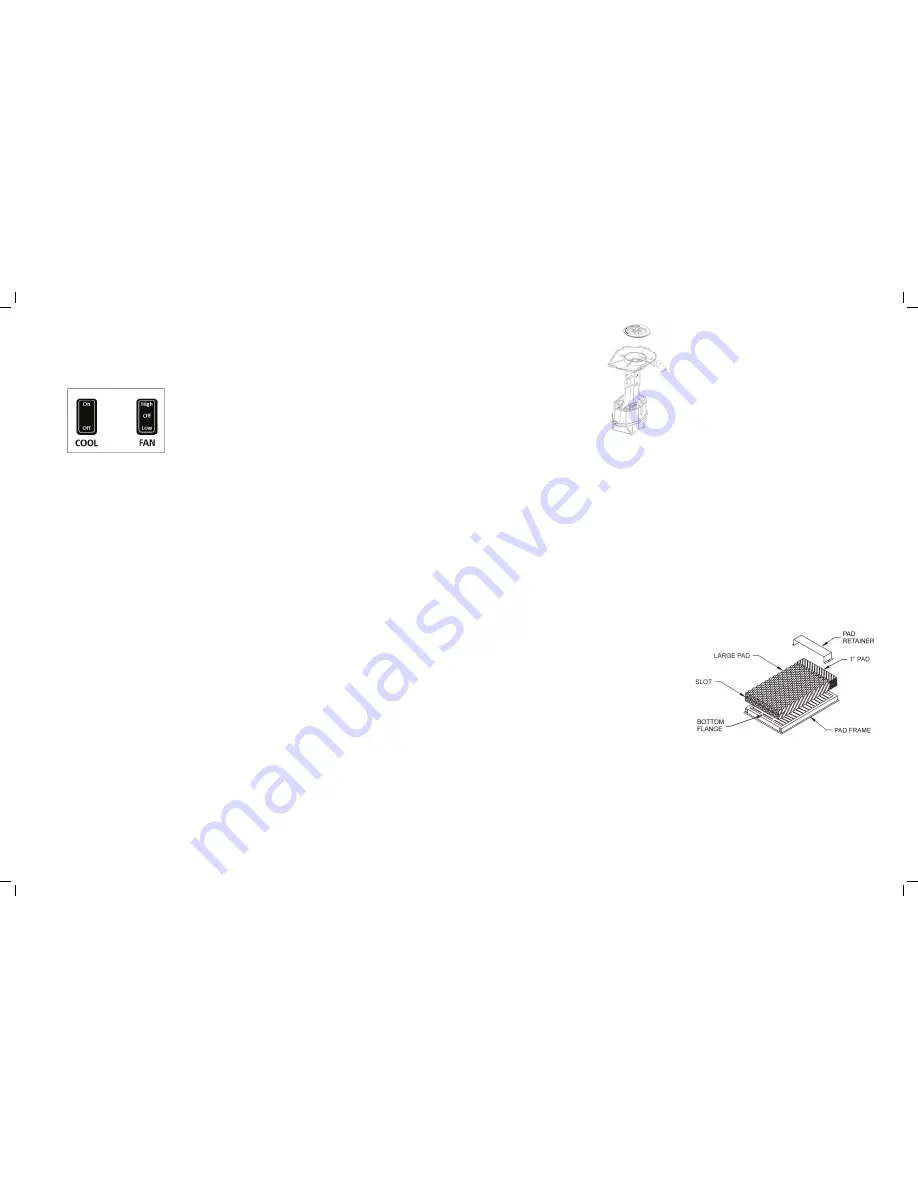

Cleaning or Replacing Media Pads

CAUTION: Disconnect all electrical power to the cooler

before attempting to install, open, or service your cooler.

The condition of your cooler pads should be checked

at least once a year; at the beginning of the season is

best. However, your pads may need to be checked more

frequently, depending on local air and water conditions. For

instance, in areas where mineral content of the water is high

or the air is dusty, deposits may build up in the cooler pads,

restricting airflow. Clean or replace pads as follows:

1. Disconnect power from unit.

2. Remove pad frame assembly from cabinet.

3. Lay pad frame on smooth, flat surface with pad retainer up.

observe the location / placement of the pad retainer.

Remove retainer by sliding it out from under the pad frame

flange. Carefully remove and discard old pad.

4. Using a mild detergent, wash dirt and scale from pad frame

and rinse with fresh water. Check slots at top of pad frame

to be sure they are open and clear. Wire brushing is not

recommended. If finish is damaged or rusting is noted,

repair area as noted in the “Touch-Up” section.

5. Place the slot in the end of the new pad over the bottom

flange of the pad frame and push the pad down against the

flange until it stops. Gently push the top of the pad into the

pad frame. Slide the 1” thick pad on top of the large pad

already in place. Replace the pad retainer by sliding the

retainer under the pad frame flanges.

6. Pre-soak pad (this will help with the wetting of the pad on

start-up) .Reinstall pad frame assembly into unit.

Draining

Drain the cooler cabinet (with power off) as follows:

1. Move cooler to the area appropriate to dump water.

2. Remove drain bushing assembly as shown in figure 4

3. Drain, clean and dry reservoir.

Alternative draining options for units that will not be moved

frequently:

1. Remove drain bushing assembly as shown in figure 4

2. Attach suitable size hose and route it to the desired drain area.

3. Put a cap on the end of the hose.

4. Drain every 8-10 hours of operation.

Drain the ice chest as follows:

1. Unplug the unit from the GFCI power outlet.

2. Move cooler to the area appropriate to dump water.

3. Remove the pad frame from the back of the unit.

4. Place the end of the ice chest drain tube outside of the drain pan.

Do not drain ice melt water into the drain pan.

5. Remove the rubber drain stop and drain.

6. Dry the all surfaces of the liner.

7. Place the ice chest drain tube back inside the cabinet and

reinstall the pad frame.

Touch-Up

The hardness, adhesion and smoothness of the internal and

external finish on your cooler makes it extremely unlikely that

scratches or chipping will occur. In the event that finish damage

does occur, it should be promptly repaired by the following

procedures:

1. Sand the area around bare metal spots.

2. Prime and paint with a quality paint.

Do not use asphalt type cooler undercoat material in water

reservoir. Undercoat will break free, clogging the pump and

water distributor.

LUBRICATION

Motor Bearings

Some motors used in Patio Pal coolers have ports for lubricating the

motor and are oiled at the factory. If the need for oiling is indicated,

see the motor nameplate for specific instructions on re-lubricating

the motor. Under normal use, these motors require oiling about

every 12 months of operation.

Do Not Over-Oil

.

Blower Shaft Bearing

Blower shaft bearings need periodic lubrication. They should be

checked 20-30 days after initial start-up of operation. The oil cups

on the bearings should be filled with a good grade of SAE 20W or

30W non-detergent oil when necessary. Under normal use, oiling is

required every three months of operation.

Do Not Over-Oil

.

Pump Bearings

The pump motor does not require lubrication.