3

Limits of use (IEC 60974-1)

The use of plasma equipment for cutting is typically discontinu-

ous as it consists of periods of effective operation (cutting) and

rest periods (while the piece is being positioned, etc.). The size

of the equipment is suitable for safe use of max. nominal cur-

rent I2 for a working time that is 40% of the total time of use.

The regulations in effect stipulate that 10 minutes is the maxi-

mum total time of use. For the work cycle, 40% of that time is

considered. Exceeding the permitted work cycle triggers the

intervention of a thermal protector which protects the inter-

nal components of the plasma cutting plant against dangerous

overheating. The intervention of the thermal protection is indi-

cated by powering on the yellow LED sited on the rack panel.

After a few minutes the thermal protection automatically re-

sets, the yellow LED goes off and the plant is ready for use

once again. This plant is built to have a protection level of IP

23 S, which means:

• That it is protected against the penetration of solid foreign

bodies with diameters in excess of Ø 12 mm.

• That it is protected against water spray hitting the surface

with an angle of incidence up to 60°.

• That the plant has been tested for withstanding harmful ef-

fects due to water getting in when the moving parts on the

equipment are moving.

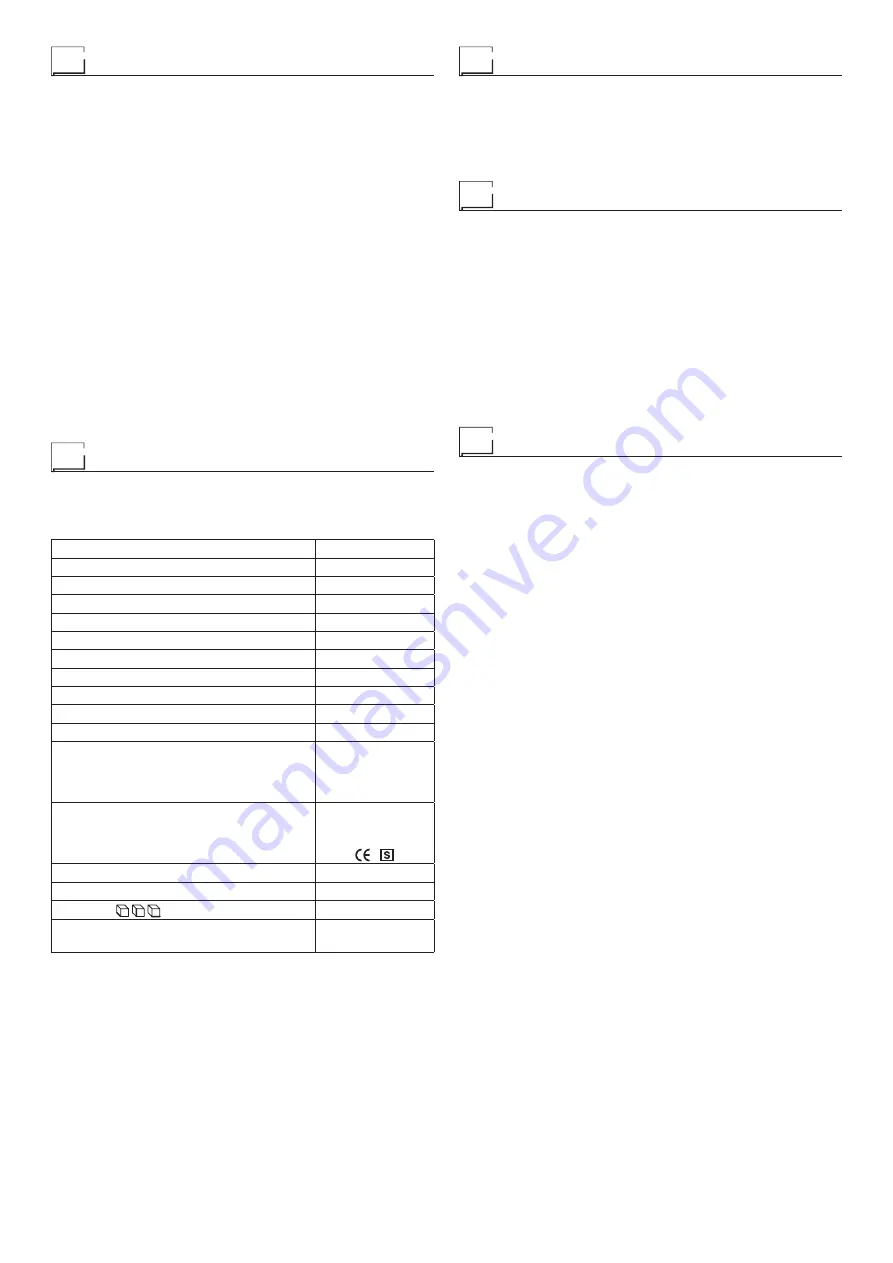

Technical data

The technical data for this equipment is summarized in the ta-

ble 1.

Table 1

Model

SHARK 35

Single-phase power supply 50 Hz (*)

V

230

Mains supply: Z

max

(**)

Ω

0,32

Power input @ I

2

Max

kVA

6,05

Delayed fuse (I

2

@ 100%)

A

16

Power factor / cosφ

0,65 / 0,99

Maximum efficiency degree

η

0,71

Open circuit voltage (peak)

V

320

Current range

A

10 ÷ 30

Duty cycle @ 60% (40°C)

A

25

Duty cycle @ 40% (40°C)

A

30

Cutting capacity

recommended

maximum

severance

mm

mm

mm

8

10

15

Standards

IEC 60974-1

IEC 60974-7

IEC 60974-10

Insulation class

IP 23 S

Protection class

F

Dimensions

mm

540-425-220

Plant weight

Plant weight including SK 25 torch

kg

18,8

20,5

(*) special 60 Hz version by request.

(**) Mains supply Z

max

: maximum impedance value allowed for

the grid according to the

EN/IEC 61000-3-11

standard.

WARNING:

This equipment does not comply with

EN/IEC

61000-3-12

. If it is connected to a public low voltage system, it

is the responsibility of the installer or user of the equipment to

ensure, by consultation with the distribution network operator

if necessary, that the equipment may be connected.

How to lift up the machine

This plant has a handle specifically for carrying the machine

by hand.

NOTE:

These hoisting and transportation devices conform to

European standards. Do not use other hoisting and transpor

tation systems.

Opening the packaging

The unit comprises the following main items:

•

SHARK 35

plasma cutting unit.

• Plasma torch with direct connector built into the plant, and

consumable “starting kit”.

• Earth cable.

• Trolley for transportation (optional).

On receipt of the unit, perform the following operations:

• Remove the plasma cutting unit and all relative accessories

and components from the packaging.

• Check that the plasma cutting unit is in good condition. If it is

not, inform your dealer immediately.

• Make sure that all the ventilation louvers are open and that

the airflow is not obstructed.

Plasma cutting

The cutting system used by this equipment is a low current sys-

tem that uses compressed air as its plasma equipment as well

as for cooling. The air normally used is a mixture of 79% nitro-

gen and 21% oxygen. These two biatomic gasses have almost

identical enthalpy and form a highly energetic blend. The low

current also makes it possible to use torches with a low air ca-

pacity and moderate cutting speed, that are more suitable for

manual procedures.

CUTTING PARAMETERS

In analyzing the parameters that characterize manual plasma

cutting it is necessary to note that they depend on the material

to be cut, its thickness and the skill of the operator in following

the cutting line. Optimum speed depends largely on the skill of

the operator and amount of material to be cut and is achieved

when the fused material flows through the groove and is not

projected in the direction of the torch. If the latter occurs, cut-

ting speed has to be reduced.

The parameters that affect cutting are:

•

Electric power.

Any increase in electric power will permit

higher cutting speed and greater thickness of the material

to be cut

•

Compressed air capacity.

Increasing the air capacity ena-

bles cutting thicker material and ensures better quality at

any thickness

•

Distance between nozzle and piece.

The appearance of the

cut and wear of the active components of the torch depends

on the nozzle being held as a correct distance from the piece.

NOTE:

The width of the cutting groove is usually about twice

the diameter of the hole in the nozzle.

Respect of the above recommendations ensures greatly redu-

ced thermal alterations of the material due to cutting, that are in

any case always fewer than those caused by oxygen tor ches.

The thermally altered zone is in any case smaller than the zone

on which the weld is effective, so that in welding pieces that

have been cut by plasma it is not necessary to perform any

cleaning or grinding operations.

Summary of Contents for SHARK 35

Page 15: ......