Chain Hoist PREMIUM PRO-E

8

5

INSPECTION, REPAIR AND

MAINTENANCE

5.1 Additional inspection

5.2 Chains and Hooks

A regular inspection via sight check has to be carried out by a according the

countries regulations authorised technician. Check for unusual noises during

load and no load tests.

For the brake system is more necessary than a simple sight check

Carry out the test as follows:

– Attach the nominal load (WLL)

– Lift the load

– Lift and release the load on different heights

– Check wheather the load is kept safely in position after the

propulsion was stopped

– Change the brake discs if the thickness is less than 2,5mm or

defects are found

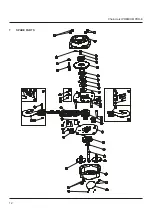

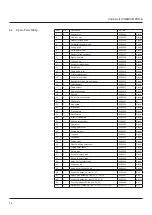

If you notice during dissambling of the hoist that parts a not ok, then change

these only against original spare parts.

Names and Spare part number of each part, you will find on the next pages.

When ordering these parts please take care to notify the correct spare part

order number, the type and capacity of the hoist.

In case of doubt send the part in for check.

Check the chain in as short intervals as possible. Check it for nicks, cracks,

cuts, dents, bendings, corrision and deformations or damages. If the cross

section of the chain link wire is reduced anywhere more than 10%, the chain

has to be substituted immediately.

– The chains and hooks have to be inspected continuously! Clean the chain

before inspection. Lubricate the load chain from time to time! Never lubri-

cate or grease the brake!

– Retracted chain shall not click under load.

– Check the chain for stretching! The internal length (t) of a worn chain link,

smallest diameter of wire (D) and length of 11 chain links (a) are measured

by a slide gauge where the chain must be tightened firmly.

– Dimensions: If the deviations of measurement exceed the values (a) in

the following table, substitute chain immediately. Measure of diameter (D)

shall not be under-run and the pitch (t) of the single link not be exceeded.