Page 5

For technical questions, please call 1-888-866-5797.

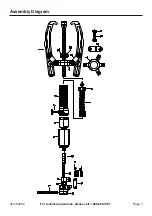

Item 64982

Maintenance and Servicing

Procedures not specifically explained in this manual

must be performed only by a qualified technician.

TO PREVENT INJURY FROM TOOL FAILURE: Do not use damaged equipment. If abnormal

noise or vibration occurs, have the problem corrected before further use.

Cleaning, Maintenance, and Lubrication

1.

BEFORE EACH USE,

inspect the general

condition of the Gear Puller. Check for loose

screws, misalignment or binding of moving

parts, cracked or broken parts, and any other

condition which may affect its safe operation.

2.

AFTER USE,

clean external

surfaces with clean cloth.

3. Lightly oil the threads and pivoting joints

periodically to keep them operating smoothly.

4. Keep Piston (2) in the fully retracted position

while in storage to prevent rust or damage.

5. If rust appears on any part of the tool,

remove it with a penetrating oil.

6. If the tool fails to perform adequately, the oil

level in the system should be checked and

air purged from the system, as follows:

Note:

This procedure should

ONLY

be

performed by a qualified technician.

a. Remove the Pump Handle Socket (12)

and Hanger Foot (14).

b. Using an oil gun, pour oil slowly into

the pump housing to overflowing.

c. Reassemble, and wipe excess

oil from the tool

.