14

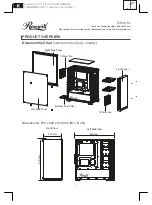

STOPPERS

11

Adjust the position of the stoppers (3) so as to

ensure a maximum opening and closing range.

Ensure that the sliding door gasket (9) is forced

against the wall.

HOURS

Apply silicone between the bottom of the fixed

panel and the threshold of the base. Silicone

application along the length of the threshold is

also suggested. In both cases, it is done from

the outside of the shower area.

3

DOOR OPEN

DOOR CLOSED

APPROX.

3” (76.2 mm)

7

6

9

3

12

SILICONE