PD-F958, PD-F908

46

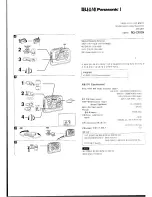

REMOVING THE ARM A2

Remove the float base together with the Servo

Mechanism ASSY GM. (Refer to Steps

for

“ Removing the Servo Mechanism ASSY GM” .)

Remove the clamp spring and remove the clamper holder.

Turn gear pulley (B) and position Arm A2 as shown

below.

Remove Arm (B) while pressing the hook in

the direction of the arrow.

Remove screw 7.

Turn gear pulley (B) and position Arm A2 as shown

below.

Remove the Arm A spring2 from its hook.

Note: Do not hold the tip (blade) of arm (A) during

operation.

Remove drive plate, Arm plate, Arm A spring2 and Arm

(A). (Refer to Steps 3-4 on page 47.)

8

9

Gear Pulley(B)

Arm A2

Hook

Arm A Spring2

Remove

Cam Cover

10

10

11

12

Lift

Screw

Gear Pulley(B)

Arm(B)

Arm A2

4

5

6

7

Arm(B)

Push

Hook

10

Clamper Holder

Remove

Clamp Spring

3

2

1

2

3

4

5

7

6

10 12

8

9

13

1

5