PREVENTIVE CHECKS AND SERVICE INTERVALS

The following standard table depends on environmental conditions and usage.

Parts replacing time does not mean the life span for individual parts.

Also, long term storage or misuse may cause transformation and aging of rubber parts.

The following list means standard hours, so the checking hours depends on the conditions.

Parts Name

Time

500

hours

1,000

hours

1,500

hours

2,000

hours

2,500

hours

Notes

Audio Control Head

7

7

7

¶

¶

Clean those parts in contact with the tape.

Full Erase Head

(Recorder only)

7

7

7

¶

¶

Capstan Belt

¶

¶

¶

¶

Clean the rubber, and parts which the rubber

touches

Pinch Roller

7

¶

¶

¶

¶

Capstan DD Unit

¶

¶

¶

¶

Loading Motor

¶

Tension Band

¶

¶

¶

¶

T Brake Band

¶

¶

¶

¶

Clutch Assy

¶

¶

¶

¶

Idler Arm Assy

¶

¶

¶

¶

Capstan Shaft

7

7

7

7

7

Tape Running Guide Post

7

7

7

7

7

Replace when rolling becomes abnormal.

Cylinder Unit

7

¶

¶

¶

¶

Clean the Head

7

: Clean

¶

: Check it and if necessary, replace it

NOTE

After cleaning the heads with isopropyl alcohol, do not run a

tape until the heads dry completely. If the heads are not

completely dry and alcohol gets on the tape, damage may

occur.

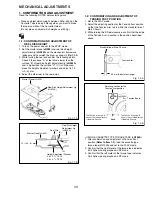

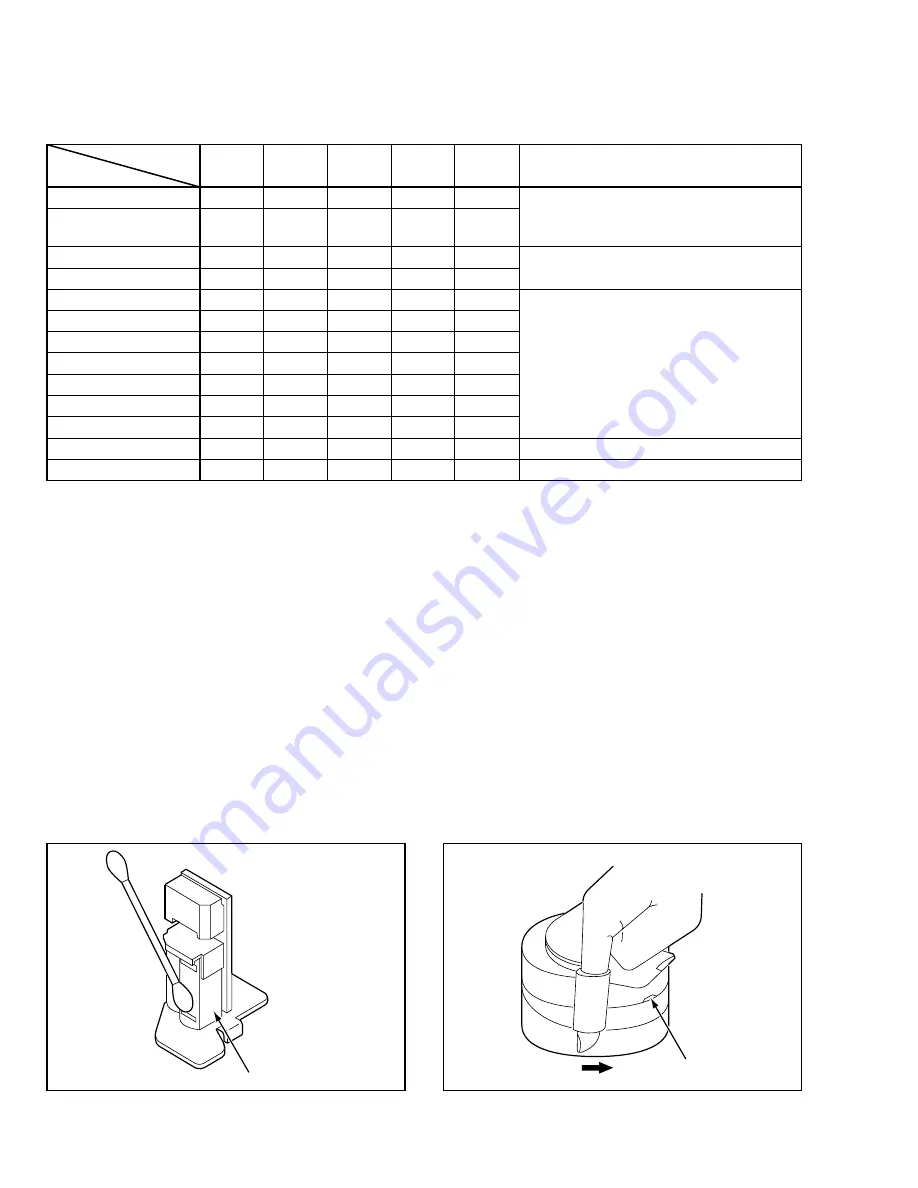

1. AUDIO CONTROL HEAD

Clean the Audio Control Head with the cotton stick soaked

by alcohol. Clean the full erase head in the same manner.

(Refer to the figure below.)

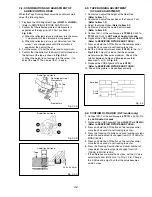

2. TAPE RUNNING SYSTEM

When cleaning the tape transport system, use the gauze

moistened with isopropyl alcohol.

3. CYLINDER

Wrap a piece of chamois around your finger. Dip it in

isopropyl alcohol. Hold it to the cylinder head softly.

Turn the cylinder head counterclockwise to clean it (in the

direction of the arrow).

(Refer to the figure below.)

NOTE

Do not exert force against the cylinder head. Do not move

the chamois upward or downward on the head.

Use the chamois one by one.

CLEANING

Audio Control Head

Cylinder Head

29