B E W E G E N | P O S I T I O N I E R E N

MS242EK 1.2.0 12/2017. 0.5

MS242EK 1.2.0 12/2017. 0.5

MS242EK 1.2.0 12/2017. 0.5

MS242EK 1.2.0 12/2017. 0.5

MS242EK 1.2.0 12/2017. 0.5

MS242EK 1.2.0 12/2017. 0.5

MS242EK 1.2.0 12/2017. 0.5

Page 2 of 8

Page 3 of 8

Page 4 of 8

Page 5 of 8

Page 6 of 8

Page 7 of 8

Page 8 of 8

B E W E G E N | P O S I T I O N I E R E N

MS242EK 1.2.0 12/2017. 0.5

Page 1 of 8

Digital Motor Controllers

MS242EK Short Instructions

C-663 / C-863 / C-867 / C-877 / C-884 / E-861 / E-871 / E-873

M O T I O N | P O S I T I O N I N G

M O T I O N | P O S I T I O N I N G

M O T I O N | P O S I T I O N I N G

M O T I O N | P O S I T I O N I N G

Start-Up

The PIMikroMove PC software is recommended

for initial start-up. With PIMikroMove, you can

temporarily or permanently adjust the settings

of the controller to the stage and start the first

motion.

CAUTION

If a protective earth conductor is not or

not properly connected, touching the

controller can result in minor injuries

from electric shock in the case of a

malfunction.

X

Connect the controller to a protec-

tive earth conductor before start-up.

X

Do

not

remove the protective earth

conductor during operation.

X

Observe the applicable standards

for the protective earth conductor

connection.

Requirements

✔

You have read and understood the PIMi-

kroMove manual and the general notes on

start-up. The software manuals are on the

controller CD.

✔

You have installed and updated the soft-

ware on the PC.

✔

You have installed the stage and the

controller as they will be used in your

application.

✔

You have connected the protective earth

conductor, stage, PC, and power supply to

the controller.

✔

If you have connected the controller to the

network or PC via the TCP/IP interface:

▪

▪

Network with DHCP server

: No ad-

justment of the factory settings of the

interface parameters is necessary.

▪

▪

Network without DHCP server or

with direct connection

(controller

connected directly to the Ethernet

connection of the PC):

▪

▪

The start-up behavior of the con-

troller must be changed so that the

controller uses a static IP address (see

manual).

▪

▪

The IP addresses and subnet masks

of the controller and PC or all other

network devices must be compatible

with each other (see manual).

✔

If available: You have set the DIP switches

of the controller according to your applica-

tion. A controller that is not an integral part

of a daisy chain network must have address

1, if it is to be used in PIMikroMove.

DIP switches

Address 1

2

3

4

5

... 16

DIP 1

ON ON ON ON ON ...

OFF

DIP 2

ON ON ON ON

OFF

...

OFF

DIP 3

ON ON

OFF OFF

ON ...

OFF

DIP 4

ON

OFF

ON

OFF

ON ...

OFF

Baud rate

9600

19200 38400 115200

DIP 5

ON

ON

OFF

OFF

DIP 6

ON

OFF

ON

OFF

Switching the Controller On

1.

Connect the power cord of the power sup-

ply with the power socket.

2.

If necessary: Move the toggle switch of the

controller to the

❙

position.

Establishing Communication with

PIMikroMove

1.

Start PIMikroMove.

The

Start up controller

window opens with

the

Connect controller

step.

X

If the S

tart up controller

window does

not open automatically, select the

Connections > New…

. menu item in the

main window.

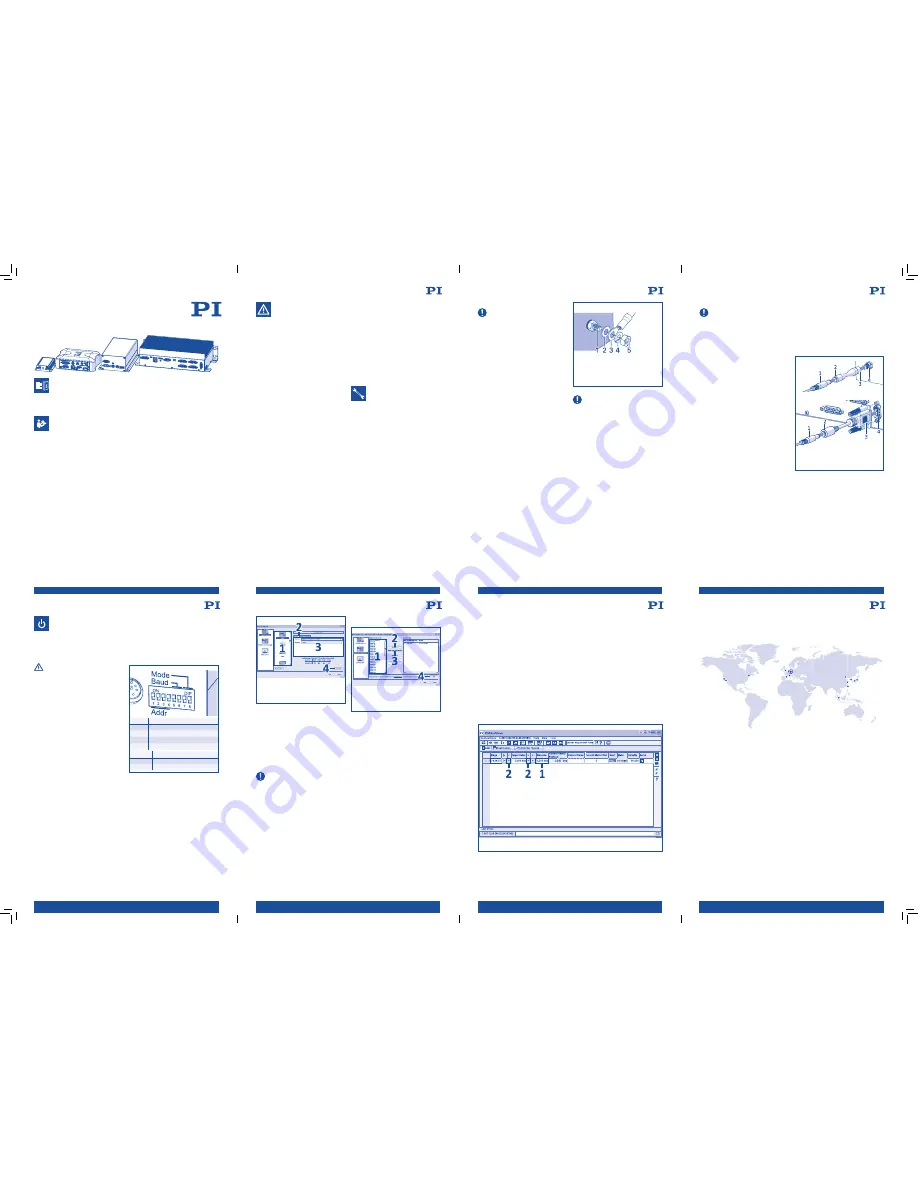

PIMikroMove: Connect controller

1

Controller selection field

2

Tabs for interface and connection type

3

Interface parameters

4 Connect

button

2.

Select the appropriate controller in the con-

troller selection field (

1

).

3.

Select the tab in the right side of the

window that corresponds to the interface

and connection type of the controller (

2

).

4.

If necessary: Set the interface parameters

according to the controller (

3

).

5.

If necessary: Select the controller from the

list (

3

).

6.

Click the

Connect

(

4

) button to establish

communication.

Starting Motions

NOTICE

Selecting an incorrect stage type in the

PC software can cause damage to the

stage.

X

Make sure that the stage type

selected in the PC software matches

the stage connected.

When the

Stage Type Configuration

window

opens:

X

Click the

Yes, configure for ...

button to

load the appropriate parameter set from

the stage database.

If the

Select connected stages

step is displayed

in the

Start up controller

window:

PIMikroMove: Select connected stages

1 Stage database entries

field

2 Assign

button

3

Assign Type from ID Chip

button

4 OK

button

1.

Select the matching stage type.

a. Mark matching stage type in the

Stage

database entries

(

1

) field.

b. Click

Assign

(

2

).

or

X

Click

Assign Type from ID Chip

(

3

)

2.

Confirm selection with

OK

(

4

) to load the

parameter settings for the selected stage

type from the stage database.

3.

In the

Save all changes permanently?

window select whether the settings of the

controller should be stored temporarily or

permanently:

▪

▪

Keep the changes temporarily

: The

settings are reset when the controller is

rebooted.

▪

▪

Save all settings permanently on

controller

: All settings are stored in the

permanent memory of the controller

and are available after rebooting or for

use with other software.

4.

If necessary: Execute the reference move

for the axis in the

Start up axes

step so

that the controller knows the absolute axis

position.

a. Click the corresponding button to start

the reference move:

▪

▪

Ref. switch

: Reference move to the

reference point switch

▪

▪

Neg. limit

: Reference move to the

negative physical limit of the travel

range

▪

▪

Pos. limit

: Reference move to the po-

sitive physical limit of the travel range

b. If a message appears warning that the

servo mode is switched off: Click the

Switch on servo

button to switch the

servo mode on (closed-loop operation).

c. After a successful reference move, click

OK

>

Close

.

The main window of PIMikroMove opens.

X

Start a few test motions of the axis.

a. Set the step size to a sensible value for

your test motion (

Step size

column,

1

).

b. Click the arrow buttons (

<

and

>

,

2

)

to start motion in the corresponding

direction with the selected step size.

Depending on the drive type and the load,

parameter changes may be necessary for fast,

precision positioning (see manual).

PIMikroMove: Main window

1 Step size

field

2

Arrow buttons

Headquarters

Physik Instrumente (PI) GmbH & Co. KG

Auf der Roemerstrasse 1

76228 Karlsruhe

Germany

Phone +49 721 4846-0

Fax +49 721 4846-1019

www.pi.ws

PI miCos GmbH

Freiburger Strasse 30

79427 Eschbach

Germany

Phone +49 7634 5057-0

Fax +49 7634 5057-99

www.pi.ws

PI Ceramic GmbH

Lindenstrasse

07589 Lederhose

Germany

Phone +49 36604 882-0

Fax +49 36604 882-4109

www.piceramic.com

Subsidiaries

US

PI (Physik Instrumente) L.P.

www.pi-usa.us

GB

PI (Physik Instrumente) Ltd.

www.physikinstrumente.co.uk

IT

Physik Instrumente (PI) S. r. l.

www.pionline.it

NL

PI Benelux B.V.

www.pi.ws

FR

PI France SAS

www.pi.ws

ES

Micos Iberia S.L.

www.pimicos.es

JP

PI Japan Co., Ltd.

www.pi-japan.jp

CN

Physik Instrumente (PI Shanghai) Co., Ltd.

www.pi-china.cn

SG

PI (Physik Instrumente) Singapore LLP

www.pi-singapore.sg

TW

Physik Instrumente (PI) Taiwan Ltd.

www.pi-taiwan.com.tw

KR

PI Korea Ltd.

www.pikorea.co.kr

Connecting the PC

NOTICE

Connecting the USB and RS-232 inter-

faces of the controller to the PC at the

same time can damage the PC or the

controller.

X

Connect either the USB or the RS-232

interface to the PC.

Requirements

✔

The PC is equipped with a vacant RS-232 or

USB interface.

or

✔

An network access point is available for the

controller.

Tools and accessories

▪

▪

Suitable cable, e.g.,

▪

▪

RS-232 null-modem cable

▪

▪

USB cable

▪

▪

Straight-through or crossover network

cable

Connecting to the USB interface

X

Connect the mini USB socket of the control-

ler and the USB interface of the PC with an

available USB cable.

Connecting to the RS-232 interface

1.

Connect the RS-232 connector of the con-

troller to a vacant RS-232 interface of the

PC via the RS-232 null-modem cable.

2.

Use the integrated screws to secure the

connection against accidental disconnec-

tion.

Connecting to a network

X

Connect the RJ-45 socket of the controller

to the network access point or PC via the

network cable.

Connecting the Power Supply to the

Controller

Requirements

✔

The power cord is

not

connected to the

power socket.

Tools and accessories

▪

▪

Power supply supplied or properly rated

power supply

▪

▪

If necessary: Adapter supplied for the

power supply connection or properly rated

adapter

▪

▪

Power cord supplied or properly rated

power cord

Connecting the power supply with adapter to

the controller

1.

Connect the adapter (

3

) to the power

supply connection (panel plug,

4

) of the

controller.

2.

Connect the barrel connector of the ad-

apter (

2

) to the barrel connector socket of

the power supply (

1

).

3.

Connect the power cord to the power

supply.

Controller with M8 panel plug

Controller with Sub-D 2W2C panel plug

1

Barrel connector of the power supply

2

Barrel connector of the adapter

3

Connector (f) of the adapter

4

Power supply connection of the controller

Connecting the power supply without adapter

to the controller

X

Connect the power supply to the power

supply connection of the controller.

X

Connect the power cord to the power

supply.

Mounting the Controller

NOTICE

High temperatures can overheat the

controller.

X

Set up the controller with a distance

of at least 10 cm to the top and rear

panels and at least 5 cm to the sides.

If this is not possible, make sure that

the environment is cooled sufficient-

ly.

X

Ensure sufficient ventilation at the

place of installation.

X

Keep the ambient temperature at a

noncritical level (5-40 °C).

When the controller is to be used as a benchtop

device:

X

Make sure that the controller is standing

safely and securely.

If the controller is to be mounted:

1.

Make the necessary holes in the surface.

2.

Affix the controller on each recess with a

suitably sized screw.

Connecting the Controller to the

Protective Earth Conductor

If a protective earth connection is available

on the controller, it must be connected to the

protective earth conductor.

Requirements

✔

The controller is switched off.

Tools and accessories

▪

▪

Suitable protective earth conductor:

▪

▪

Cable cross section ≥0.75 mm²

▪

▪

Contact resistance < 0.1 ohm at 25 A

at all connection points relevant for

mounting the protective earth con-

ductor

▪

▪

Mounting material for the protective earth

conductor; is on the protective earth con-

nection on delivery of the controller

▪

▪

Suitable wrench

Connecting the protective earth conductor

1.

Fasten a suitable cable lug to the protective

earth conductor.

2.

Affix the cable lug of the protective earth

conductor to the protective earth connecti-

on using the mounting material supplied.

Connecting the protective earth conductor

using threaded bolt

1

Threaded bolt

2

Flat washer

3

Cable lug with protective earth conductor

4

Safety washer

5

Nut

Connecting the Stage

NOTICE

Connecting a stage with incompatible

drive type to the controller can cause

irreparable damage to the stage or

controller. Even stages with mechanically

compatible connectors can be electrically

incompatible with the controller.

X

Only connect stages to the controller

that have a compatible drive type.

Requirements

✔

The controller is switched off.

✔

You have read and understood the user

manual of the stage.

Tools and accessories

▪

▪

Stages with compatible drive type and

connector

▪

▪

If necessary: Compatible adapter from PI

▪

▪

Optional: Suitable extension cable from PI

Connecting the stage

1.

Connect the motor connector of the stage

to the

Motor

socket of the controller.

2.

If necessary: Connect the sensor connector

of the stage to the

Sensor

panel plug of the

controller.

3.

Use the integrated screws to secure the

connections against accidental disconnec-

tion.

General Safety Instructions

Intended Use

The controller is a laboratory device as defined

by DIN EN 61010-1. It is intended for indoor use

and use in an environment that is free of dirt,

oil, and lubricants.

In accordance with its design, the controller

is intended for the closed-loop operation of

stages. In addition, it can read and process the

reference point and limit switch signals from

the stage connected.

The controller may only be used in compliance

with the technical specifications and instruc-

tions in this user manual. The user is responsi-

ble for process validation.

The controller may not be used for purposes

other than those mentioned in the user manual.

The controller may only be installed, operated,

maintained, and cleaned by authorized and

appropriately qualified personnel.

Installation

Unsuitable cables can cause damage to the

controller and can affect the performance of

the stage.

X

Only use original PI parts to connect the

stage to the controller.

X

If you need longer cables, use extension

cables from PI.

Start-Up

The collision of a moving part at the end of the

travel range, or with an obstacle, as well as high

accelerations, can cause damage to or consi-

derable wear on the stage.

X

Avoid motion in open-loop operation

or stop the axes in time. Do

not

disable

evaluation of the limit switches via the

parameter setting.

Unsuitable servo-control parameter settings of

the controller can cause the stage to oscillate.

Oscillations can damage the stage and/or the

load affixed to it.

X

If the stage is oscillating (unusual operating

noise), immediately switch off the servo

mode or the controller.

X

Only switch on the servo mode for the axis

on the controller after you have modified

the servo-control parameter settings (see

manual).

X

If, due to a very high load, oscillations occur

already during the reference move, follow

the instructions in the manual for the refe-

rence move in „Troubleshooting“.

Installation

Installing the PC Software

Installing the PC software in Windows

1.

Start the installation wizard by double-cli-

cking the

PI_<product code>.CD_Setup.

exe

file in the installation directory (main

directory of the CD).

The

InstallShield Wizard

window for the

installation of programs and manuals for

the controller opens.

2.

Follow the instructions on the screen.

3.

If necessary: Update the PC software and

stage database using PIUpdateFinder (see

manual).

Installing the PC software in Linux

1.

Unpack the tar archive from the

/linux

directory of the product CD to a directory

on your PC.

2.

Change to the directory where the tar

archive was unpacked.

3.

As superuser (root rights), execute the

./INSTALL

script to start the installation.

4.

Follow the instructions on the screen.

5.

If necessary: Update the PC software and

stage database (see manual).

M O T I O N | P O S I T I O N I N G

M O T I O N | P O S I T I O N I N G

M O T I O N | P O S I T I O N I N G

M O T I O N | P O S I T I O N I N G

User Information

These short instructions contain an overview of the most important safety instructions and

handling instructions for installation and start-up of motor controllers with the above-mentioned

product codes.

Downloading and Reading the Manual

The actions during installation, start-up, operation, adapting the settings, and maintenance require

additional information from the manuals of the controller and/or the stage used.

Manuals may be titled as follows: „User Manual“, „Technical Note“.

Download the manuals from the website

1. Read the product code on the product (e.g., C-863.11).

2. Open the website

www.pi.ws

.

3. For password-protected manuals (CD in the scope of delivery of the product):

a. Insert the CD into a PC.

b. Read the user name and password in the

Releasenews

file in the

\Manuals

folder

on the CD

.

c. Click

Login

.

d. Log in with the user name and password.

4. Click

Search

.

5. Enter the product code up to the period (e.g., C-863) into the search field.

6. Click

Start search

or press the

Enter

key.

7. If necessary: Click

Load more downloads

at the end of the list.

8. Click the corresponding product to open the product detail page.

9. Scroll down to the

Downloads

section.

The manuals are displayed under

Documentation

.

10. Click the desired manual and save it to the hard disk of your PC or to a data storage medium.

If you cannot find the manual you are looking for or if you have any questions: Contact our custo-

mer service department via [email protected].