onlinecomponents.com

P1 ENGRAVING UNIT

12

PHOENIX CONTACT

103072_00_en

Cleaning the Motor Filter

Figure 22

Motor filter

•

If the cover has been opened as described above, the

motor filter can be removed.

•

Carefully remove the motor filter from the chamber for

the vacuum cleaner bag.

Simply clean this filter as required.

Handling the Engraving Spindle

Cleaning the Engraving Spindle

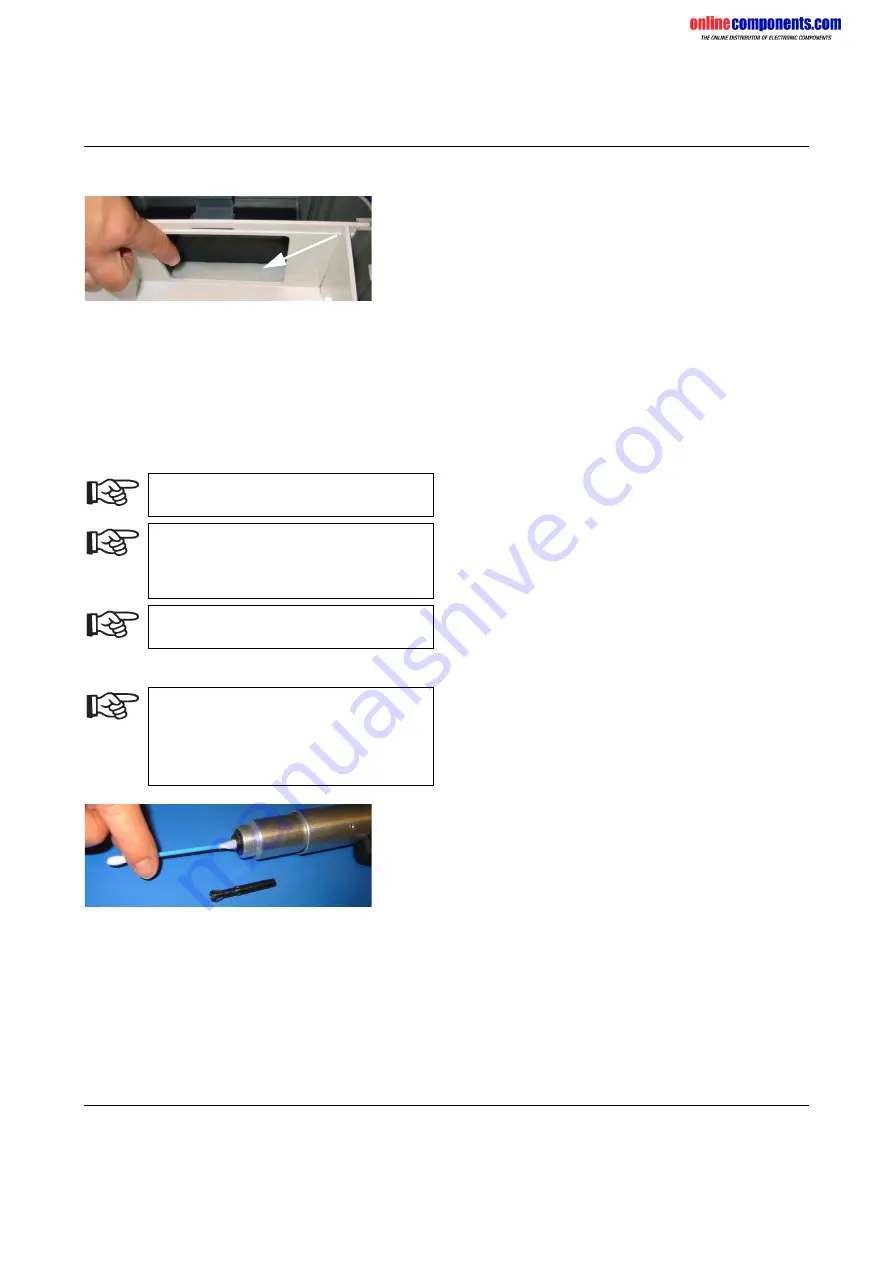

Figure 23

Cleaning the collet chuck of the engraving

spindle

•

Remove the graver and unscrew the collet chuck

completely using the rotary knob (see page 10).

•

Wipe the front part of the collet chuck seat with a clean

cotton bud.

•

Switching from Engraving to Plotting

To switch from engraving back to plotting, perform the

above in reverse order.

•

Switch off the plotter and control unit and disconnect

the mains plug on both devices.

•

Disconnect the suction tube and connecting cable from

the engraving head.

•

Disconnect the control unit from the plotter and vacuum

cleaner.

•

Remove the support pipe with holder.

•

Remove the cover from the engraving head.

•

Remove the terminal screw and remove the engraving

spindle.

•

Release counter bearing.

•

Release the interlocking device on the engraving head

and pull the engraving head out of the plotter arm.

•

Assemble the pen lowering unit and insert the locking

pin. Fit the plastic cover.

Then change the default values for engraving mode:

•

In the CMS-MARK-WIN software, select the

"Settings... Default values..." menu.

•

On the "Plotter output" tab, adjust the following items:

– Change the speed for all items to 2 cm/s.

– Activate the "Startup function" option, if required.

– Confirm the parameters with "OK".

The engraving spindle is a sensitive unit and

must be handled with extreme care.

Only use the engraving spindle in dust-free

rooms. An excessively high level of dust can

result in the sensitive bearing becoming

clogged with dust and quickly wearing out.

Do not use a lubricant for engraving.

Never clean the engraving spindle with

compressed air, as this will remove lubricant

from the ball bearings.

Never use water to clean the engraving

spindle.