18

DELL P1230 M25P

Electrical Instructions (Continued)

Go to cover page

8. Focus adjustment

9. Loading DDC code

- Apply a video signal in the 1280 x1024 with 146kHz/85 Hz

mode

- Select " M/E " pattern.

- Set the brightness at center (50%) and the contrast to

MAX.-position.

- Adjust focus potentiometers (top of L.O.T.) Focus 1 for

horizontal focus and Focus 2 for vertical focus so that the

picture at 2/3 of the diagonal lines (from center to four corners)

of the displayed screen is as sharp as possible.

The DDC HEX data should be written into the DDC IC by

EEPROM (7804) writer or EDID301.EXE program and Software

DDC Alignment Kit.

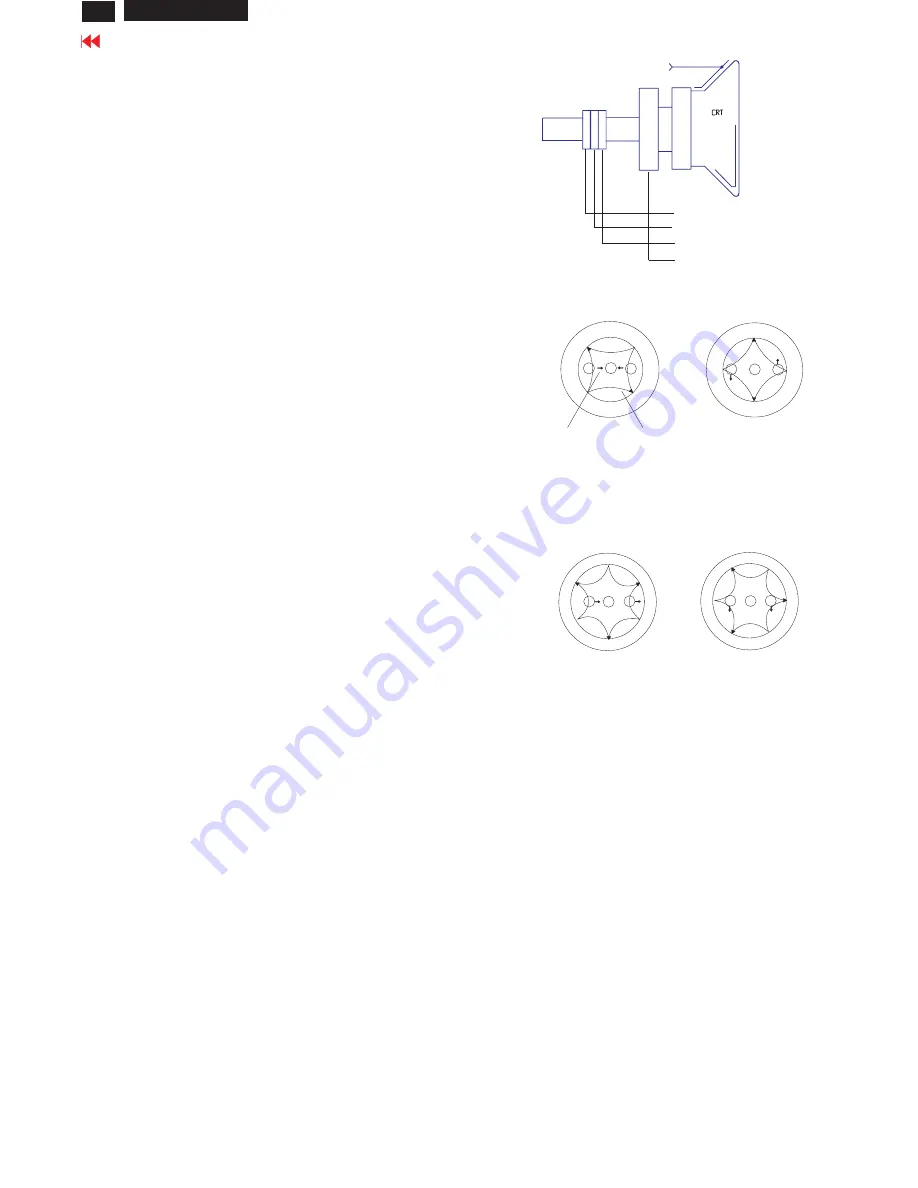

Purity Adjustment

1. Purity adjustment

2. Static convergence

- Make sure the monitor is not exposed to any

external magnetic field.

- Produce a full red pattern on the screen, adjust the

purity magnet rings on the PCM assy (on CRT) to

obtain a complete field of the color red. This is done

by moving the two tabs (2-pole) in such a manner

that they advance in an opposite direction but at

the same time to obtain the same angle between

the two tabs, which should be approximately 180

degree.

- Check by full green pattern and full blue pattern

again to observe their respective color purity.

Introduction

Slight deviation in the static convergence can be

corrected by using two permanent pairs of magnets

which are fitted around the neck of the CRT. These

are the 4-pole magnet and the 6-pole magnet.

The 4-pole magnet move the outermost electron

beams (R and B) parallel in the opposite direction

from the other. The 6-pole magnet moves the

outermost electron beam (R, B and G) parallel in the

opposite direction from the other.

The magnetic field of the above magnets do not affect

S

S

N

N

B

G

R

S

S

N

N

B

G

R

Beam displacement

direction

Magnetic flux

lines

6-pole

Beam motion producced by the

6- pole convergence magnet

S

S

S

N

N

N

R

B

G

S

S

S

N

N

N

R

B

G

4-pole

Beam motion producced by the

4-pole convergence magnet

2-pole purity magnet

6-pole convergence magnet

4-pole convergence magnet

Deflection Yoke

the center of the CRT neck.

Setting

- Before the static convergence setting can be made,

the monitor must be switched on for 30 minutes.

- The focus setting must be made correctly.

- Signal: 640 * 480, 31.5 kHz/60 Hz mode.

- Set the tabs of the 4-pole magnet in the neutral

position. This is when the tabs are opposite one

another. In this position the magnets do not affect the

deflection of the R and B electron beams.

- Set the tabs of the 6-pole magnet in the neutral

position. This is when the tabs are opposite one

another. In this position the magnets do not affect the

deflection of the R, B, and G electron beams.

- First set the 4-pole magnet optimally.

- Then set the 6-pole magnet optimally.

- If the convergence is not now optimal, then adjust to

the optimal setting with the 4-pole magnet and then with

the 6- Pole magnet again.

- Set the tabs of the 6-pole magnet in the neutral

position. This is when the tabs are opposite one

another. In this position the magnets do not affect the

deflection of the R, B, and G electron beams.

- First set the 4-pole magnet optimally.

- Then set the 6-pole magnet optimally.

- If the convergence is not now optimal, then adjust to

the optimal setting with the 4-pole magnet and then

Summary of Contents for DELLP1230

Page 10: ...10 DELL P1230 M25P ...

Page 22: ...Go to cover page 22 DELL P1230 M25P Terminal Schematic Diagram ...

Page 23: ...23 DELL P1230 M25P Terminal Panel C B A 2 Go to cover page ...

Page 25: ...25 DELLP1230 M25P Drive Panel C B A 1 Go to cover page ...

Page 26: ...Go to cover page 26 DELL P1230 M25P Drive Panel C B A 2 ...

Page 28: ...Go to cover page 28 DELL P1230 M25P Video Panel C B A 1 ...

Page 29: ...29 DELL P1230 M25P Video Panel C B A 2 Go to cover page ...

Page 32: ...Go to cover page 32 DELL P1230 M25P Main Panel C B A 1 ...

Page 33: ...33 DELL P1230 M25P Main Panel C B A 2 Go to cover page ...

Page 34: ...Go to cover page 34 DELL P1230 M25P Key Control Panel Schematic Diagram C B A ...

Page 35: ...35 Go to cover page MHR Schematic Diagram DELL P1230 M25P ...

Page 79: ...79 Repair Flow Chart Go to cover page 7 0 2 Dell P1230 M25P ...