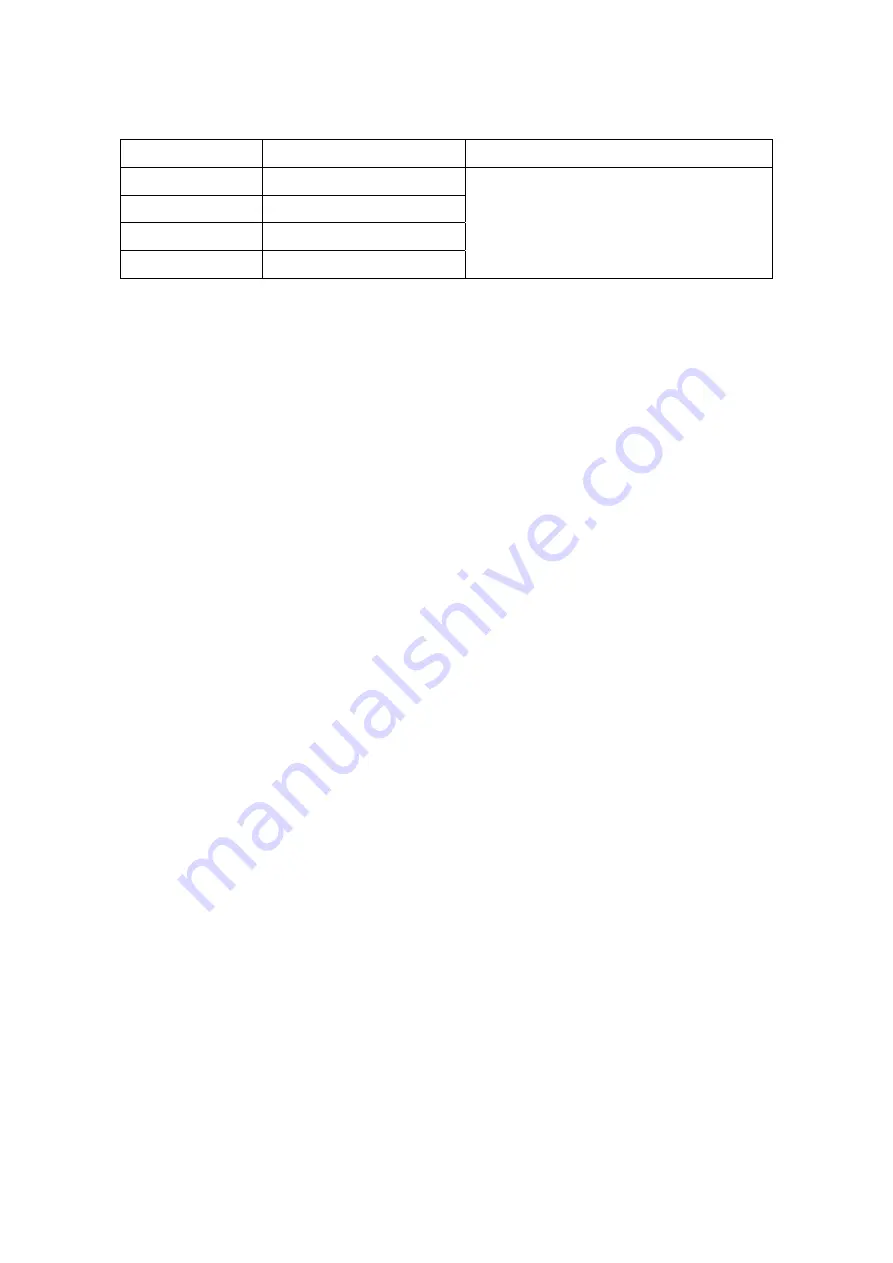

(1) Purge flow

Dry-Vac Model

Amount (

㎥

/min N)

Remark

200 0.55

300 0.55

400

0.8 ~ 0.86

800 Above

1

This purge amount can

Vary as per the pump’s vacuum level

(2) Type of Cooling Purge

①

Standard : Atmosphere purge through air filter

②

Using Heat Exchanger : Recycle process gases from discharge after cooled through the

heat exchanger.

③

Using Inert gases like N2 etc. Instead of atmosphere or cooled process gas.

●

Sealing Purge

This purge is required during the operation and intended to pressurize the front end cover with

Inert gas like N2 so that the process gas or fluid can not enter into the timing gear set and

bearings. You can use either one of two plugs provided on the top of Front End Cover for this

sealing purge connection.

The purge pressure is below 0.5

㎏

/

㎠

G and the leak rate for our Mech. seal is below 3cc/Hr.

Also our Mechanical seal can seal pressure up to 3

㎏

/

㎠

G.

●

Cleaning Purge

This purge is required to clean inside the pump before stopping the pump. Before stopping the

pump, purge N2 gas, steam or cleaning agent for 20 to 30 minutes after closing the main valve

on suction side to clean sticky process materials or process gases. This purge is important

when pumping corrosive/toxic gases or sticky materials like resin.

●

Pump Steam Flushing

After each process, run the pump for 10

∼

20 minutes without load after close main suction

valve (Dry run, Cleaning purge).

This is to remove & clean process gases / condensed vapors the pump during the process.

These process materials build up inside the pump can be the reason for pump overload when

restart the pump for next process.

Also, when restart the pump after a certain period later, these process materials can be cause

for pump seizure or overload.

In this case, flush steam the pump internals & Screws with following procedure instead of

rotating the pump with force.

◐

Steam Flushing Method (after operation)

(1) Process materials that require Steam flushing: Monomer, Polymer, Resin, etc.

(2) Steam pressure: approx. 1

㎏

/

㎠

G

(3) Flushing Procedure

5