NOTICE

Property damage from incorrect cleaning procedure

Flushing fluid and process media that enters the bearing and oil chambers will stick.

► During the cleaning processes, always protect all bearings with sealing gas in order to prevent a

contamination of the lubricant and bearing chambers.

The clearance between pistons and housing are within a tenth of a centimeter range. Sustained, accu-

mulating contamination has the following effect:

● the friction heat inside the roots pump increases

● the power consumption of the roots pump increases

● the pistons jam

Required aids

● Brushes and cleaning agents

● Suitable vessel for collecting the cleaning fluid

● Absorbent materials for absorbing the cleaning fluid

Procedure

1. Dismantle the pipes from the vacuum and fore-vacuum connections.

2. Clean the suction chamber and the overflow channel with suitable brushes and cleaning agents.

3. After cleaning, completely remove remaining fluids using absorbent materials, and dry the suction

chamber.

4. After cleaning, mount all pipes.

5. Screw in the drain screws.

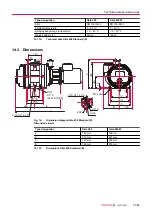

7.6 Cleaning the overflow valve

1

2

3

4

5

7

6

9

8

Fig. 12:

Overflow valve

1 Allen head screws

6

Pressure screw

2 Valve cover

7

Compression piece

3 O-ring

8

Valve plate

4 Ball

9

Pump housing

5 Compression spring

Required tools

● Allen key, WAF 6 mm

● Calibrated torque wrench (tightening factor ≤ 2.5)

Remove the overflow valve

1. Unscrew the screws and remove the valve cover.

2. Be careful with O-ring.

3. Remove the valve plate from the overflow channel.

4. Unscrew and remove the pressure screw and at the same time remove the compression spring,

compression piece, and ball.

5. Clean and dry the guide pin from the valve cover.

Maintenance

37/54