As the soiling increases, the throughput of the gas ballast filter decreases. The risk of condensation and

corrosion in the vacuum pump increases.

Required consumables

● Compressed air

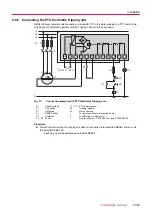

1

2

3

Fig. 21:

Cleaning the gas ballast filter

1 Gas ballast filter

3

Gas ballast line

2 Gas ballast valve

Removing and cleaning the gas ballast filter

1. Dismantle the gas ballast filter.

2. Clean the gas ballast filter using compressed air.

3. Replace the gas ballast filter in the event of major contamination or damage.

4. Check and clean the gas ballast line using compressed air if the gas ballast line is clogged.

7.7 Changing the operating fluid type

Possibilities for changing the operating fluid type

The operating fluid type can be changed between mineral operating fluid –

P3

– and syn-

thetic operating fluid –

D1

– only.

It is not possible to change from

P3/D1

to

F4/F5

or vice versa.

Required consumables

● 3 times the filling quantity of the new operating fluid

Changing the operating fluid type

1. Change the operating fluid with the new operating fluid

twice

in order to rinse the vacuum pump.

2. Change the exhaust filters in the operating fluid separator.

3. Change the operating fluid filter.

4. Fill the vacuum pump with operating fluid to one third full.

5. Note the currently used operating fluid type at a suitable location on the vacuum pump, e.g. on the

rating plate.

Maintenance

41/60