© 2009

14

24” ADA-Compliant Series Operation / Installation Manual

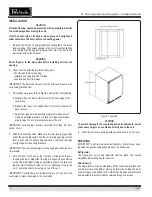

WOODEN WINE RACK TRIM FINISHING

All wine racks come with an unfinished solid hardwood face, which can

be removed and replaced with other wood to match the surrounding

cabinetry.

The included unfinished faces can be finished and sealed. In many

cases, stains and/or finishes have odors that may be objectionable in

an enclosed area. To remove the front wood face from the wine shelf,

simply pull out the wine shelf and remove the fasteners. Finish as

desired and re-install with original fasteners.

OPERATION

General

The unit is equipped with a state-of-the-art refrigeration system and

is a frost-free model. The evaporator coil automatically defrosts on

demand at predetermined intervals.

Interior Light

The unit is equipped with an interior light that illuminates when the

door is opened. A manual switch is located next to light for displaying

the product through a glass door. Always ensure the manual switch is

in the off position before closing a solid wood or stainless steel door. If

manual switch is left on for an extended period of time, it may increase

the cabinet temperature, especially at the top, and cause the refrigera-

tion system to run longer.

Loading Product

IMPORTANT: Before storing perishables, allow unit to run for a mini-

mum of 24 hours to allow temperature stabilization after start-up.

When loading items into unit, do not block internal louvers and fan

guard openings or performance will be decreased.

Temperature Control

The controller is located at the top rear panel of the cabinet (Figure

11). Approximate temperature operating ranges are:

Refrigerator:

33°F minimum, 39° maximum

Wine Reserve:

40°F minimum, 65° maximum

Beverage Center: 36°F minimum, 48° maximum

A

DJUSTING

T

EMPERATURE

• Colder Temperatures: Turn the adjusting screw clockwise (to the

right).

• Warmer Temperatures: Turn the adjusting screw counterclockwise

(to the left).

• Temperature Control “OFF”: Turn the adjusting screw completely

counterclockwise to the “OFF” position until a click is heard.

The condenser fan and motor turns off and on with the compressor.

Checking Product Temperature

To accurately check the temperature of the product stored in a refrig-

erated compartment, insert an accurate thermometer into a sealable

plastic (non-breakable) bottle, partially filled with water. Tighten the

cap securely.

Figure 10. Wooden Wine Rack Trim

1

/

8

” x 0.312” deep

5

/

8

”

5

/

16

”

7

1

/

4

”

8”

1

17

/

32

”

1

1

/

2

”

18

5

/

16

”

1

/

16

” to

1

/

8

”

radius all

outside edges

1

/

2

”