Do not operate the engine with the Instruction

Plate cover removed from the clutch. Personal in-

jury may result.

If the clutch is damaged to the point of burst fail-

ure, expelled pieces can cause personal injury to

anyone in the immediate area. Proper safeguards

must be followed to help prevent accidents.

i08254039

Radiator

-

Clean

Note:

Adjust

the

frequency

of

cleaning

according

to

the

effects

of

the

operating

environment.

Inspect

the

radiator

for

these

items:

damaged

fins,

corrosion,

dirt,

grease,

insects,

leaves,

oil,

and

other

debris.

Clean

the

radiator,

if

necessary.

Personal injury can result from air pressure.

Personal injury can result without following prop-

er procedure. When using pressure air, wear a

protective face shield and protective clothing.

The maximum air pressure for cleaning purposes

must be reduced to 205 kPa (30 psi) when the air

nozzle is deadheaded.

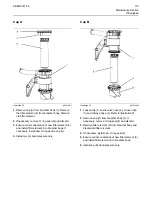

Pressurized air is the preferred method for removing

loose debris. Direct the air in the opposite direction of

the air flow. Hold the nozzle approximately 6 mm

(0.25 inch) away from the fins. Slowly move the air

nozzle in a direction that is parallel with the tubes.

This movement will remove debris that is between

the tubes.

Pressurized water may also be used for cleaning.

The maximum water pressure for cleaning purposes

must be less than 275 kPa (40 psi). Use pressurized

water to soften mud. Clean the core from both sides.

Use a degreaser and steam for removal of oil and

grease. Clean both sides of the core. Wash the core

with detergent and hot water. Thoroughly rinse the

core with clean water.

After cleaning, start the engine and bring the engine

to high idle. This procedure will help in the removal of

debris and drying of the core. Stop the engine. Use a

light bulb behind the core to inspect the core for

cleanliness. Repeat the cleaning, if necessary.

Inspect the fins for damage. Bent fins may be opened

with a “comb”. Inspect these items for good condition:

welds, mounting brackets, air lines, connections,

clamps, and seals. Make repairs, if necessary.

i02568202

Starting

Motor

-

Inspect

Perkins

recommends

a

scheduled

inspection

of

the

starting

motor.

If

the

starting

motor

fails,

the

engine

may

not

start

in

an

emergency

situation.

Check

the

starting

motor

for

proper

operation.

Check

the

electrical

connections

and

clean

the

electrical

connections.

Refer

to

the

Service

Manual

for

more

information

on

the

checking

procedure

and

for

specifications

or

consult

your

Perkins

distributors

for

assistance.

i06101140

Walk-Around

Inspection

Inspect

the

Engine

for

Leaks

and

for

Loose

Connections

A

walk-around

inspection

should

only

take

a

few

minutes.

When

the

time

is

taken

to

perform

these

checks,

costly

repairs

and

accidents

can

be

avoided.

For

maximum

engine

service

life,

make

a

thorough

inspection

of

the

engine

compartment

before

starting

the

engine.

Look

for

items

such

as

oil

leaks

or

coolant

leaks,

loose

bolts,

worn

belts,

loose

connections,

and

trash

buildup.

Make

repairs,

as

needed:

• The guards must be in the proper place. Repair

damaged guards or replace missing guards.

• Wipe all caps and plugs before the engine is

serviced in order to reduce the chance of system

contamination.

NOTICE

For any type of leak (coolant, lube, or fuel) clean up

the fluid. If leaking is observed, find the source and

correct the leak. If leaking is suspected, check the flu-

id levels more often than recommended until the leak

is found or fixed, or until the suspicion of a leak is

proved to be unwarranted.

NOTICE

Accumulated grease and/or oil on an engine or deck

is a fire hazard. Remove this debris with steam clean-

ing or high pressure water.

116

SEBU9071-06