8

5

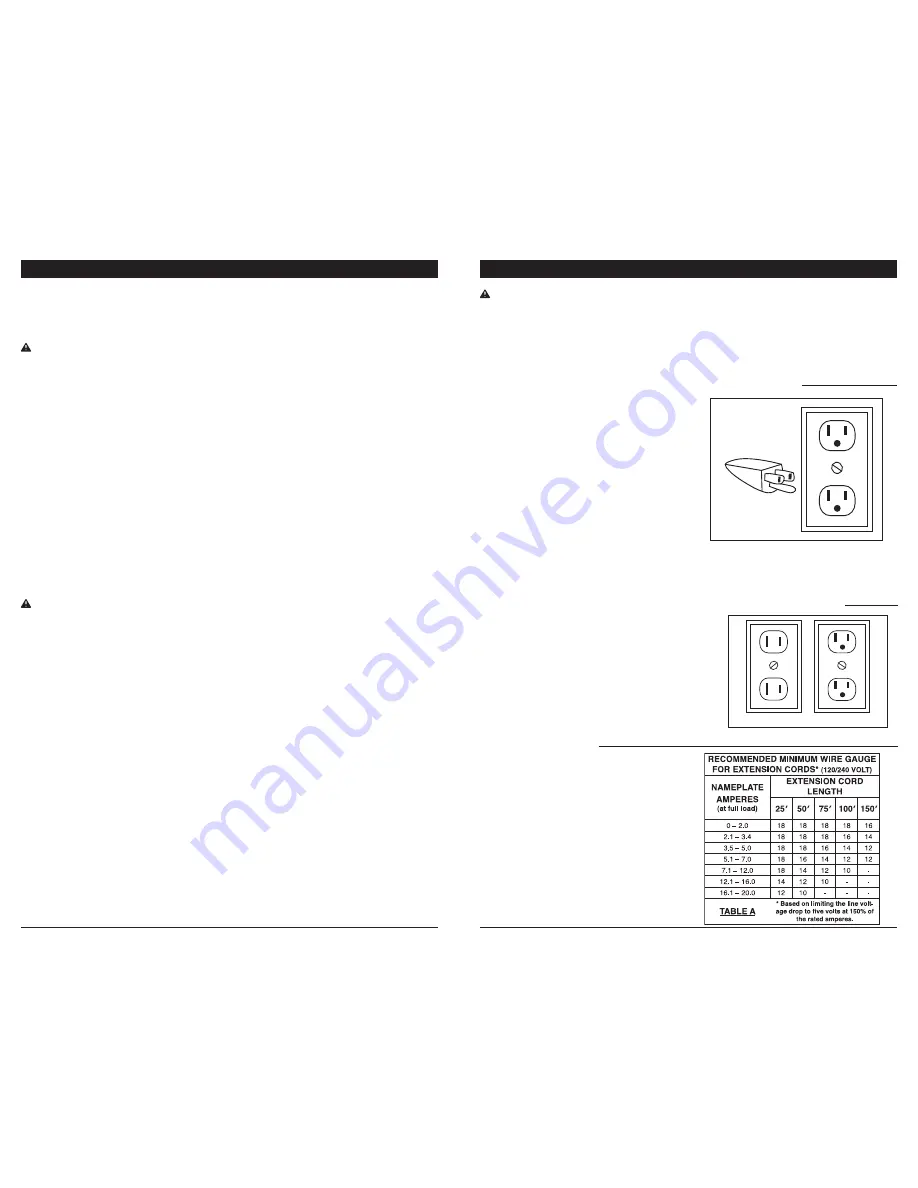

Figure B

1. Grounded tools require a three wire extension cord.

Double Insulated tools can use either a two or three

wire extension cord.

2. As the distance from the supply outlet increases,

you must use a heavier gauge extension cord.

Using extension cords with inadequately sized wire

causes a serious drop in voltage, resulting in loss of

power and possible tool damage. (See table a.)

3. The smaller the gauge number of the wire, the

greater the capacity of the cord. For example, a 14

gauge cord can carry a higher current than a 16

gauge cord. (See table a.)

4. When using more than one extension cord to make

up the total length, make sure each cord contains at

least the minimum wire size required. (See table a.)

EXTENSION CORDS

1. Tools marked with “Grounding Required” have

a three wire cord and three prong ground-

ing plug. The plug must be connected to a

properly grounded outlet. If the tool should

electrically malfunction or break down,

grounding provides a low resistance path to

carry electricity away from the user, reducing

the risk of electric shock. (See Figure A.)

2. The grounding prong in the plug is connected

through the green wire inside the cord to

the grounding system in the tool. The green

wire in the cord must be the only wire con-

nected to the tool’s grounding system and

must never be attached to an electrically “live”

terminal. (See Figure A.)

3. Your tool must be plugged into an ap-

propriate outlet, properly installed and

grounded in accordance with all codes and

ordinances. The plug and outlet should look

like those in the following illustration. (See

Figure A)

DOUBLE INSULATED TOOLS: TOOLS WITH TWO PRONG PLUGS

GROUNDING

GROUNDED TOOLS: TOOLS WITH THREE PRONG PLUGS

Figure A

1. Tools marked “Double Insulated” do not

require grounding. They have a special double

insulation system which satisfies OSHA

requirements and complies with the applicable

standards of Underwriters Laboratories, Inc.,

the Canadian Standard Association, and the

National Electrical Code. (See Figure B.)

2. Double insulated tools may be used in either

of the 120 volt outlets shown in the following

illustration. (See Figure B.)

WARNING: TO PREVENT ELECTRIC SHOCK AND DEATH FROM INCORRECT

GROUNDING WIRE CONNECTION. Check with a qualified electrician if you are in

doubt as to whether the outlet is properly grounded. Do not modify the power cord plug

provided with the tool. never remove the grounding prong from the plug. Do not use the

tool if the power cord or plug is damaged. if damaged, have it repaired by a service

facility before use. if the plug will not fit the outlet, have a proper outlet installed by a

qualified electrician.

OPERATION

5. Plug the Power Cord into an electrical

extension cord (not included). Then,

plug the extension cord into a grounded,

GFCI-protected, 120 volt electrical outlet.

WARNING

To prevent electric shock,

keep cord connection off ground.

NOTE

: Always start and stop the Polisher/

Sander while it is held firmly against the

surface of the vehicle. Failure to do so may

result in the Foam Pad or Polishing Bonnet

being thrown from the Polishing Pad.

6. To start, position the unit on the area to

be polished, grip the Polisher/Sander

firmly with both hands and press the

Trigger. Release the Trigger to stop. To

use the Lock on button, while holding in

the Trigger, press the Lock On Button,

then release the Trigger. The Polisher/

Sander will stay on. Press and release

the Trigger to stop.

7. Keep pressure off of the Polisher/Sander

when operating. The Foam Pad should

LIGHTLY contact the polishing surface.

CAUTION

To prevent damage to the

foam pad, polishing bonnet, and vehicle

finish: Only apply the pad/bonnet flat

against the surface, see below.

8. Begin using the Polisher/Sander to apply

wax to the vehicle. Apply the wax to

all flat surfaces with broad, sweeping

strokes in a crisscross pattern. Apply

the wax evenly over the surface of the

vehicle.

9. Add additional wax to the Polishing Pad

as needed. To add additional wax:

A. Stop the tool and allow the Polisher/

Sander to come to a complete stop.

B. Add a small amount of wax evenly

over the pad surface.

C. Avoid using too much wax. For

additional applications of wax to Foam

Pad, reduce the amount of wax. The

Foam Pad will not absorb as much

wax in subsequent applications.

D. Resume operation.

NOTE

: The most common error when wax-

ing/polishing a vehicle is applying too much

wax. If the Foam Pad becomes saturated

with wax, applying wax will be more difficult

and will take longer. Applying too much wax

may also reduce the life of the Foam Pad.

If the Foam Pad continually comes off the

Backing Pad during use, too much wax may

have been applied.

10. After the wax has been applied to the

vehicle’s surface, turn off the Polisher/

Sander. Unplug the Power Cord from

the electrical extension cord.

11. Remove the Foam Pad from the

Backing Pad and with your hand and

the Foam Pad, apply wax to any hard

to reach areas of the vehicle such as

around lights, door handles, under

bumpers, etc.

12. Allow sufficient time for the wax to dry.

13. Place a clean Polishing Bonnet (sold

separately) securely onto the Backing

Pad.

NOTE

: Tightly pull the string to secure

the Polishing Bonnet. Secure the string

and keep it out of the way by tying several

knots.

NOTE

: Start and stop the Polisher/Sander

only while it is held firmly against the

surface of the vehicle. Failure to do so may

result in the Bonnet being thrown from the

Backing Pad.

14. Start the Polisher/Sander and begin

buffing off the dried wax.

15. When you have removed as much wax

as you can with the Polisher/Sander,

turn off and unplug the Polisher/Sander.

16. Remove the Polishing Bonnet from

Backing Pad. Using the Polishing

Bonnet, remove the wax from all hard to

reach areas of the vehicle.

SANDING

1. Make sure that the surface to be sanded

is wiped clean of all dirt and debris,

especially that of previous courser

sanding sessions, which will scratch the

surface of a finer grit sanding session.

2. Attach the desired grit Sanding Disk

(sold separately) onto the Backing Pad.