Read all safety warnings before operation.

WARNING!

All persons in the work area must always wear approved eye and ear protection and

approved breathing apparatus when this spray gun is in operation.

Never aim spray gun at anyone. Do not spray near sparks, open flame, lit cigarettes, pilot

lights, space heaters or any other potential ignition source. DO NOT SMOKE IN WORK

AREA.

Follow manufacturers instructions and safety information to ensure safe handling and

proper use of paints, lacquers, thinners, base coats, etc. Do not use latex or other heavy

paints. They are not recommended for this spray gun.

Warning! Solvents 1,1,1-Trichloroethane and Methylene Chloride (Dichlormethane - some-

times called Methylchloride) can chemically react with the Aluminum used in most spray

equipment creating an explosion hazard. Read the label or data sheet from the mate-

rial you intend to spray. NEVER USE ANY MATERIAl CONTAINING THESE SOlVENTS. If

unsure as to the composition of your material, check with your supplier. Do not use acids

for cleaning.

Always keep work area free from obstructions and well ventilated.

Always disconnect spray gun from air source before disassembly.

SPECIFICATIONS

IMPORTANT SAFETY INFORMATION

3

WARNING!

Failure to heed these warnings may result in personal injury or property damage.

Specifications are subject to change without notice

*

Operating Pressure

15 - 45 PSI

Spray pattern

3" - 7"

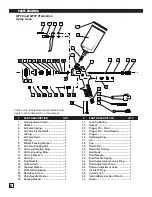

Spray Head & Needle

1.3 mm (M706 & M707)

1.5 mm (M706 & M707)

1.7 mm (M707)

Cup capacity

1000 ml.

Avg. air consumption

7.0 - 9.0 CFM

Fluid inlet

3/8" NPS

Air inlet

1/4" NPS

Hose size

3/8" I.D.

Controls:

• Spray pattern, fluid flow and inlet air pressure

• All purpose gun sprays primers, base coats, sealers,

clear coats

• Fully adjustable spray pattern

• Locking pressure regulator with pressure gauge

• 1000 ml paint cup

• Includes wall hanger, multi-wrench, cleaning brush,

socket and fluid filter

HVLP NOTICE

This High Volume low Pressure

(HVlP) compliant spray gun was

designed to provide maximum transfer

efficiency by limiting air cap pressure

to 10 PSI when used properly.

To maintain a maximum air cap

pressure of 10 PSI at the nozzle,

use a maximum of 36 PSI at the inlet.

*