TROUBLESHOOTING

Detected Errors

NOTE: It can take up to 30 seconds for an error to be detected

and displayed. All errors on each timer in the system

must be displayed before the errors can be corrected.

If a communication error is detected, an Error Screen will

alternate with the Main (time of day) Screen every few seconds.

• All units In Service remain in the In Service position.

• All units in Standby go to In Service.

• Any unit in Regeneration when the error occurs

completes Regeneration and goes to In Service.

• No units are allowed to start a Regeneration Cycle while

the error condition exists, unless they are manually forced

into Regeneration.

• When an error is corrected and the error no longer

displays (it may take several seconds for all of the units

in a system to stop displaying the error message), the

system returns to normal operation.

NOTE: During the error condition the control continues

to monitor the flow meter and update the volume

remaining. Once the error condition is corrected all

units return to the operating status they were in prior

to the error. Regeneration queue is rebuilt according

to the normal system operation. Or, if more than

one unit has been queued for regeneration, then the

queue is rebuilt according to which one communicates

first.

Cause For Error

Correction

One or more units have a

missing or bad communication

cable.

Connect the communication

cables and/or replace.

One or more units has a

communication cable plugged

into the wrong receptacle.

Connect the communication cable

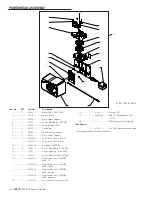

as shown in the wiring diagrams.

One or more units is not

powered.

Power all units.

Programming Errors

During the error condition the control continues to monitor the

flow meter and update the remaining capacity. Once the error

condition is corrected all units return to the operating status

they were in prior to the error and regeneration is queued

according to the normal system operation. If reprogramming

the unit in the Master Programming Mode clears the error, the

volume remaining may be reset to the full unit capacity (i.e. as

though it were just regenerated).

• All units in Standby go In Service.

• Any unit in regeneration when the error occurs completes

regeneration and goes to In Service.

• No units are allowed to start a regeneration cycle while

the error condition exists.

When the problem is corrected and the error no longer displays

(it may take several seconds for all of the units in a system

to stop displaying the error message), the system returns to

normal operation.

Programming Errors Detected

• Duplicate unit addresses or numbers

• Size of system ex: if sized for a 4 units, and only have 2 units

• Display format mismatches

Solution

• Program the units correctly in the Master Programming

Mode.

Cause For Error

Correction

Any or all of two or more units

programmed with the same

unit number (Matching Address

Error)

Program the units correctly in

the Master Programming Mode

Flashing/blinking display

Power outage has occurred

Format Mismatch (Units have

both U.S. and Metric Formats)

Verify all units have same Format

selected (all U.S. or all Metric)

No messages displayed/small

black squares appear in display

Turn the contrast button on the

back of unit until text appears

Size Error (Units not correctly

numbered/more than one unit

has the same number assigned)

Check each unit and verify each

as the correct number, and that

each number is used once

Com Error (Communication

Error)

Check the wiring of the system

and verify it is correct and that

all are connected

NOTE: If these errors are detected, numbers 1 through 3

become true, and the main screen (time of day) will

alternate with an error screen.

20 •

FLECK

7000 NXT Service Manual