3

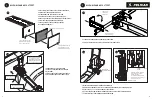

ASSEMBLE AND ADJUST FEET

PRESS TWO (2) BLACK SNAP FACES TIGHTLY TOGETHER.

REMOVE TAPE LINER ON ONLY ONE SIDE.

ENSURE MOUNTING FOOT SURFACE IS CLEAN

AND DEGREASED. LINE UP TAPE SQUARE TO FOOT.

PRESS THIS ADHESIVE FACE FIRMLY ON ADJUSTABLE FOOT.

LEAVE TAPE LINER ON OTHER SIDE FOR NOW.

TAKE CARE TO NOT TOUCH ADHESIVE SURFACE

WITH HANDS OR OBJECTS.

TEMPORARILY HOLD SADDLE ARM IN

TRUCK BED TO DETERMINE FOOT LENGTH

ADJUSTMENT.

THIS MAY VARY BETWEEN THE TWO SADDLE

ARMS, OR NEED FINE ADJUSTMENT LATER.

INSERT DETENT KNOB WITH LOWER ARM HORIZONTAL

KNOB MUST BE THREADED FULLY IN, TO LOCK ARM HORIZONTALLY FOR SUPPORTING CASE.

REPEAT STEPS 3.1 - 3.4 FOR OTHER MOUNT SUBASSEMBLY.

TO AVOID SCRATCHING PAINT ON LOWER ARM, TAKE CARE TO ALWAYS UNTHREAD KNOB

SUFFICIENTLY TO CLEAR LOWER ARM BEFORE ROTATING.

3.4

DETENT KNOB

(Right Hand Thread)

Foot resting on wall.

Flip over if needed.

Note which slot positions

will be used for bolts.

Place L-bracket on rail in

desired case location.

Hold saddle arm against it

with lower arm horizontal.

Place foot against bed wall.

3.2

3.1

Remove the adhesive liner.

Firmly press adhesive side

to face of mounting foot.

Snap black faces together tightly.

Leave this adhesive liner in

place until later step, for

final adjustments of mount.

FIT M6 BOLTS THROUGH SQUARE HOLES IN SADDLE ARM.

PARTIALLY TIGHTEN M6 LOCKNUTS, FOR FINAL ADJUSTMENT LATER.

Adjust to bed wall

and level the case.

Flip foot over

if required to

fit bed wall.

3.3

3.5

VERTICAL: STOWED

DETENT

HOLES

KNOB

Lower arms have two (2) detent

holes that must be used for

locking in position:

One hole in horizontal position

to support case; one vertical, to

stow case (not-in-use).

3

ASSEMBLE AND ADJUST FEET

3

4