Contact

PELA Tools

Solängsvägen 13

SE-513 70 Borås

Phone: 033-202650

E-mail: [email protected]

Environmental protection /

Scrapping

Recycle any unwanted material,

do not throw it in the household

rubbish. All machines, accessories

and packaging must be sorted and

left at a recycling center and disposed of in an

environmentally friendly manner.

Technical specification

Headstock taper................................................. MK 2

Tailstock taper.................................................... MK 2

Tool rest........................................................ 150 mm

Speed ....................680, 1000, 1430, 2000, 2800 rpm

Dimensions (L).............................................. 850 mm

Engine power.................................................... 600 W

Voltage.............................................................. 230 V

Net weight.......................................................... 40 kg

Save this manual

You will need this manual for safety instructions, in

-

stallation instructions, operating instructions, parts

list and diagrams. Keep your manual in a safe, dry

place for future reference.

Read all instructions before using this tool.

1. Keep the work area clean. Messy areas invite

injuries.

2. Consider the working conditions. Do not use

the tool in humid, wet or poorly lit places. Do

not expose to rain.

3. Keep children away. All children should be kept

away from the work area. Do not allow them to

handle tools or extension cords.

4. DO NOT OVERDRIVE TOOLS. It will make the

job better and safer at the pace for which it was

intended.

5. USE THE RIGHT TOOL. Do not force a small tool

or accessory to do the work of a larger

industrial tool. Do not use a tool for a purpose

for which it was not intended.

6. DRESS PROPERLY. Do not wear loose clothing

or jewelry. They can be caught in moving

parts. Protective gloves and non-slip shoes are

recommended for work. Use protective hair

covering to keep long hair away so that it does

not get caught in the machine.

7. USE EYE PROTECTION. Wear ISO-approved

safety goggles.

8. SAFE WORK. Use clamps or a screw to hold the

workpiece if possible. It is safer than using your

hands and it frees both hands to use the tool.

9. TREAT TOOLS WITH CARE. Keep tools sharp

and clean for better and safer performance.

Follow the instructions for lubrication and

replacement of accessories. Inspect tool cords

regularly and if they are damaged, have them

repaired by an authorized service center. Keep

handles dry, clean and free of oil and grease.

10. AVOID ADJUSTMENT KEYS AND PROTECTION.

Make it a habit to check that keys and

adjustment keys are removed from the tool or

machine work surface before use.

11. BE ALERT. Look at what you do, use common

sense. Do not use tools when you are tired.

12. INSPECT DAMAGED PARTS. Before using any

tool, carefully inspect any part that appears

to be damaged to determine that it is working

properly and can perform the intended function.

Check for adjustment of moving parts,

breakage of parts, assembly and other

conditions that may affect its function. Every

part that is damaged must be properly repaired

by an authorized service center unless

otherwise stated in the operating instructions.

13. REPLACEMENT OF PARTS AND ACCESSORIES.

Use only identical spare parts for service. Use

only accessories intended for use with this tool.

14. DO NOT USE THE TOOL IF YOU ARE AFFECTED

BY ALCOHOL OR DRUGS. Read prescription

warning labels to determine if your judgment

or reflexes are impaired while you are taking

drugs. If in doubt, do not use the

machine.

15. NEVER STAND ON THE TOOL. Serious damage

can occur if the tool tips over.

16. KEEP PROTECTION IN PLACE. Never use the

machine unless all guards are working

properly.

17. NEVER USE A TOOL IF ITS COVER OR ANY

BOLTS ARE MISSING. If casings or bolts have

been removed, replace them before use.

Maintenance so that all parts are in good

condition.

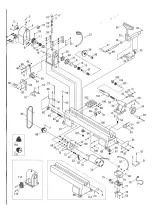

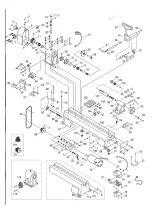

Summary of Contents for 494213

Page 1: ...Tr svarv 450 mm Wood lathe 450 mm Item No 494213...

Page 5: ......

Page 8: ......

Page 12: ......

Page 15: ......