7 of 39

ISSUED: 11-20-06 SHEET #: 202-9179-2 12-05-06

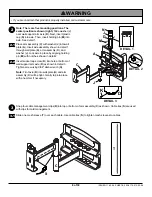

IMPORTANT! Concrete must be 2000 psi density

minimum.

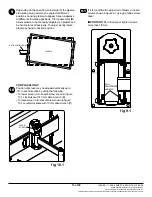

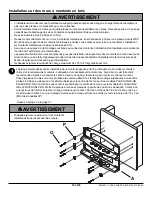

Use wall plate (A), making sure that it is level, as a

template to mark holes. The top mounting slots

should be located .36" above the desired screen

center for PLA 60-UNLP-GB and PLA 60-UNLP-GS

and .43" below the desired screen center for PLAV

60-UNLP-GB, PLAV 60-UNLP-GS. Use the masonry

bit to drill 5/16" (8 mm) dia. holes to a minimum depth

of 3" (76 mm). Insert anchors (W) in holes flush with

wall as shown (right). Place wall plate (A) over an-

chors and secure with 5/16 x 3" wood screws (O) and

washers (P).

• Concrete must be 2000 psi density minimum. Lighter density concrete may not hold concrete anchor.

• Make sure that the supporting surface will safely support the combined load of the equipment and all attached

hardware and components.

• Never exceed the Maximum UL Load Capacity of 175 lb (79 kg).

• Never mount this product to metal studs.

WARNING

• Always attach concrete expansion anchors directly to

load-bearing concrete.

• Never attach concrete expansion anchors to concrete

covered with plaster, drywall, or other finishing mate-

rial. If mounting to concrete surfaces covered with a

finishing surface is unavoidable, the finishing surface

must be counterbored as shown below. If plaster/

drywall is thicker than 5/8", custom fasteners must be

supplied by installer.

WARNING

• Tighten wood screws so that wall plate is firmly

attached, but do not overtighten. Overtightening can

damage screws, greatly reducing their holding power.

• Never tighten in excess of 80 in • lb (9 N.M.).

WARNING

1

Installation to Concrete Wall

A

O

P

W

concrete

surface

1

3

2

Drill hole(s) and insert anchor(s) (W)

mounting

plate

Place plate

over anchor(s) (W) and secure with screw(s)(O)

Tighten all fasteners

W

W

INCORRECT

CORRECT

CUT

A

W

A

Y

VIEW

mounting

plate

plaster/

dry wall

concrete

mounting

plate

concrete

plaster/

dry wall