15 of 22

2016-09-07 SHEET #: 180-9091-1

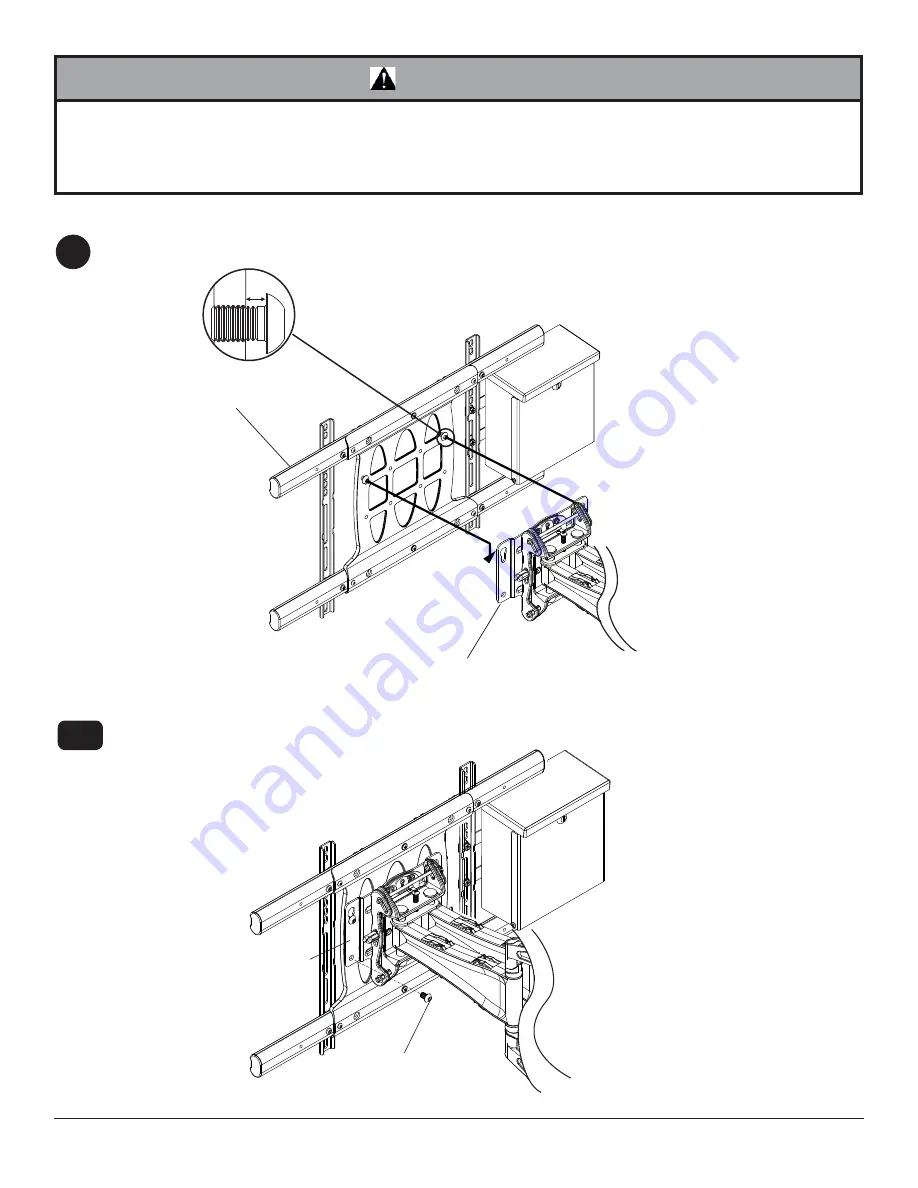

Hook M10 x 15 mm screws into keyslots of wall arm adapter plate as shown fi gure 7.1.

Insert two M10 x 15 mm screws included with wall arm into bottom holes of wall arm adapter plate as shown in

fi gure 7.2. Tighten all fasteners with a 6 mm allen wrench.

Skip to step 11.

7-1

WALL ARM ADAPTER PLATE

DISPLAY NOT

SHOWN FOR

CLARITY

DISPLAY NOT

SHOWN FOR

CLARITY

• Do not lift more weight than you can handle. Use additional man power or mechanical lifting equipment to safely

handle placement of the display.

• Do not tighten screws with excessive force. Overtightening can cause damage to mount.

Tighten M10 x 15 mm

screws (

E

) to 40 in. • lb. (4.52 N.M.) maximum torque.

WARNING

Mounting Flat Panel Display

7

1/4"

M10 X 15 MM SCREW

fi g. 7.1

fi g. 15.2

M10 X 15 MM SCREW

WALL ARM ADAPTER PLATE

ADAPTER PLATE