12

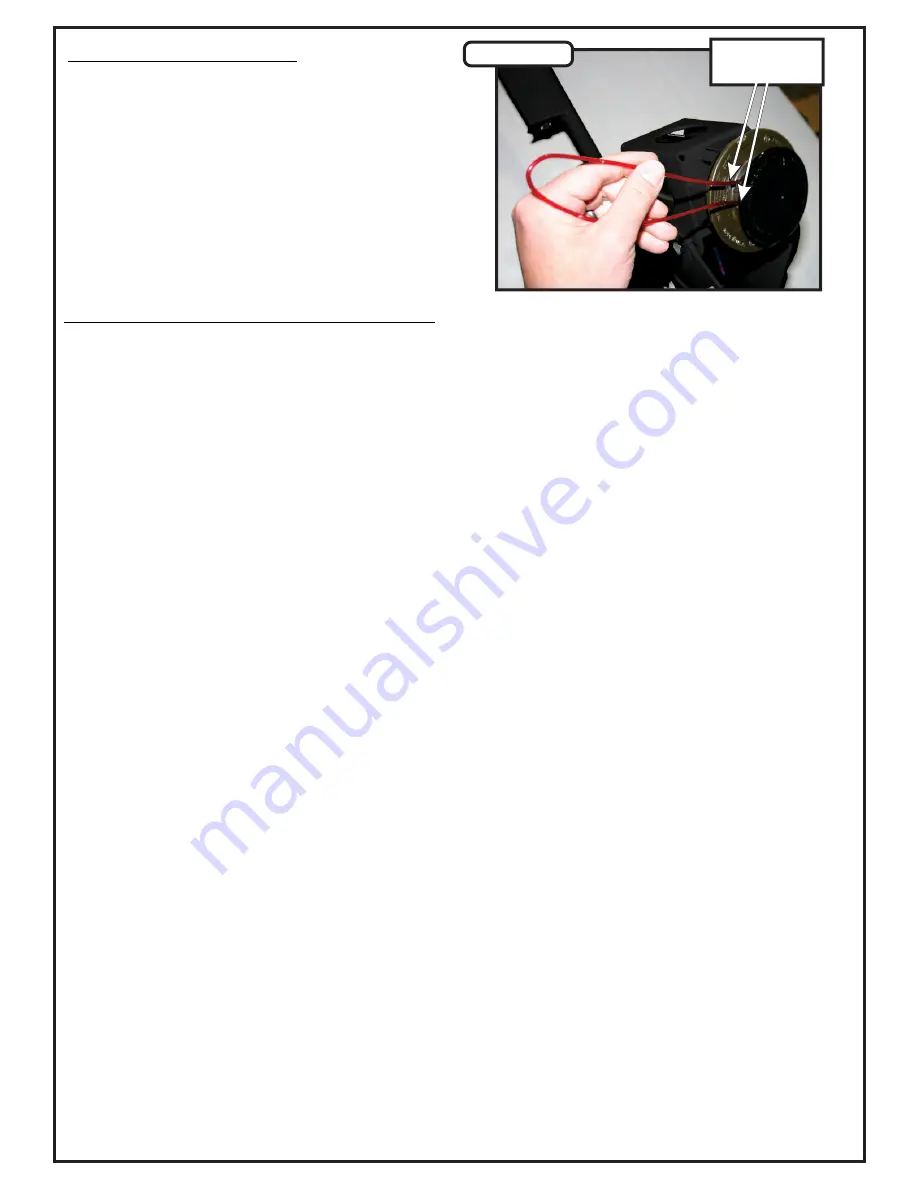

To replace trimmer line, bend a new line into two equal

lengths, insert the line ends into the holes on the trimmer

head. The head will automatically route the line out the

correct hole. Pull each end taught and adjust if uneven.

Refer to Figure A. To order more trimmer line P#(ZT-

0017), contact PECO at (800) 438-5823.

Section 6 Trimmer Line

Insert Line

Into Both Holes

Figure A

—

If the circuit breaker trips repeatedly, slow your speed and/or adjust your height setting.

Section 7 Tips and Recommendations

—

Because the Z-Trimmer runs off your machine’s charging system, it is recommended to operate the machine at full

throttle when using the Z-Trimmer.

—

Inspect the Z-Trimmer before each and every use. Examine the base plate to ensure the Z-Trimmer is tightly

secured to your machine. Make sure the power cable is secure. Check all moving parts for damage or obstruction.

Inspect the trimmer head and line.

—

Check the head shroud for any debris before using the Z-Trimmer. Clean if necessary.

—

Keep your trimmer line in an easily accessible, but secure place on your machine. Practice replacing the trimmer

line from the operator seat to save time.

—

If the Z-Trimmer gets hung up or caught on something,

STOP

and

TURN THE POWER OFF

before inspecting the

situation.

—

Ensure the Z-Trimmer is in the correct angle (trimming/edging) and that the star knob is tightened securely before

use.

—

Always inspect the area you are trimming before operating your Z-Trimmer. Look for anything that could potentially

get caught up in the trimmer head, or damage the trimmer.

Summary of Contents for Z Trimmer ZT-3000

Page 13: ...13 ZTA 0100 Z Trimmer Assembly Exploded View...

Page 14: ...14 ZTA 0100 Z Trimmer Assembly Exploded Parts List...

Page 15: ...15 ZTA 0004_01 Pivot Block Assembly Exploded Parts List...

Page 17: ...17...

Page 19: ...19...