BALLISTICS PRESSURE TRANSDUCER MODELS 165B02 AND 118A07 OPERATION MANUAL

3

Selected Values for 77°F (25°C)

Measured resonant frequencies may differ slightly from

the chart values due to variations in the velocity of

sound in the air from changes in temperature and

pressure of the air in the passage.

If possible, keep passage lengths below 0.10 inches

(.254 mm) for best results in most ballistic applications,

especially at the casemouth and when measuring port

pressures.

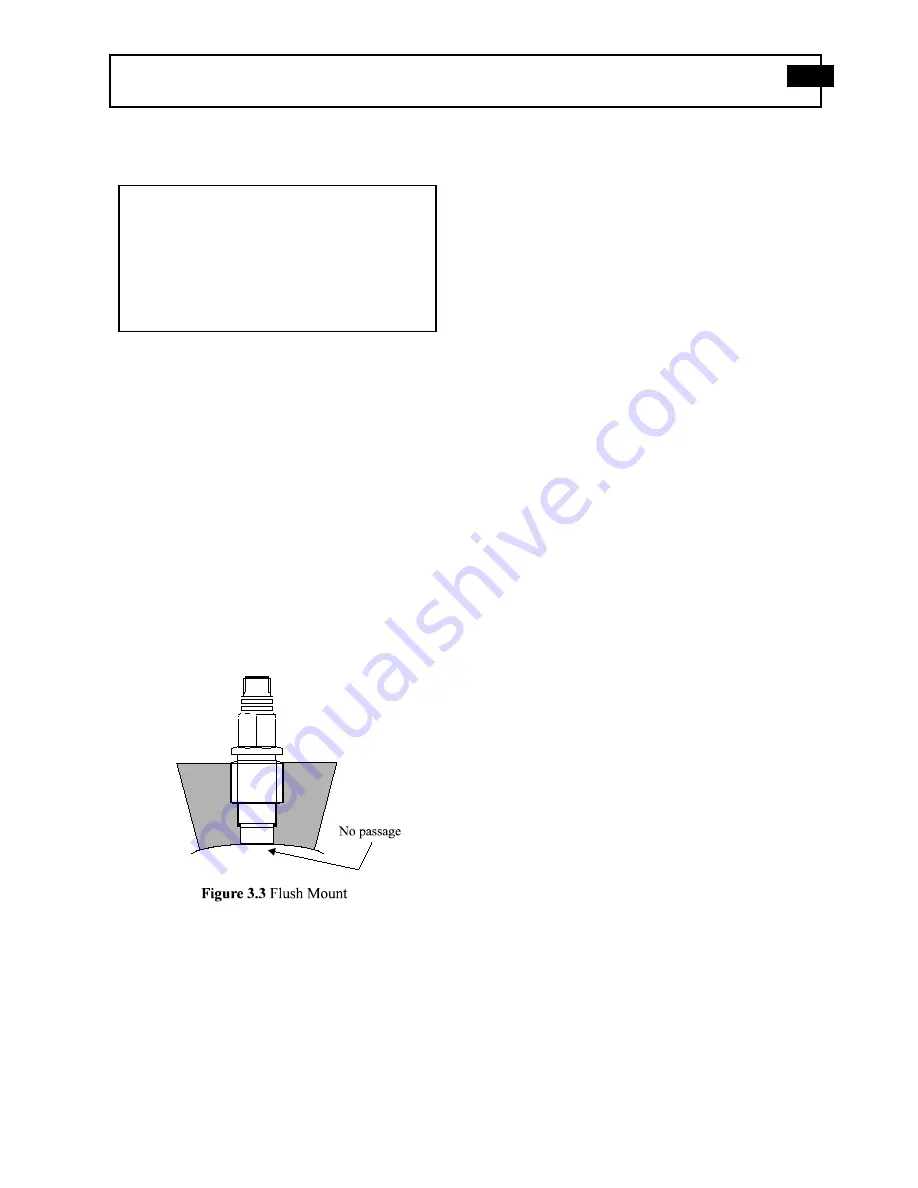

3.4

Flush Mount

The flush mount installation is intended for tangential

shot shell pressure measurement and there is no reduced

area passage from the sensor diaphragm to the test

chamber. Instead, the sensor diaphragm is mounted flush

with, or slightly recessed from, the inside surface of the

test chamber. See Figure 3.3.

If thermal transients or diaphragm impingement are

concerns, use the flush mount technique only when

space or rise time considerations preclude the use of the

recess mount installation.

3.5

Flash Thermal Protection

Additional steps may be taken to provide protection

from flash thermal effects. The sensor diaphragm may

be thermally insulated with DC-4 silicone grease or its

equivalent. In place of the silicone rubber, one layer of

black vinyl electrical tape on the diaphragm may provide

sufficient insulation.

3.6

Cable Installation

Use only low-noise treated coaxial cable (PCB Model

003A or equivalent) to connect the transducer to the

charge amplifier, in-line voltage amplifier, or other high

input impedance readout instrument. For further details

on such cabling contact PCB.

Protect the ultra high impedance connection against

moisture contamination with shrink tubing or other

suitable method. Figures 5.1 and 5.2 illustrate typical

circuit connections.

It is advisable to support transducer cables by tying them

to rigid structures to prevent excessive motion that can

generate noise and materially shorten cable life. Allow

adequate strain relief.

4.0

CALIBRATION

This transducer can be calibrated using either static

hydraulic techniques, such as by a dead weight tester, or

by comparison with a standard dial gauge.

Set the charge amplifier for a long time constant, and

allow the transducer to thermally stabilize before

attempting to calibrate it.

Passage

Passage

Approx. fastest

length

resonance

pulse rise time

(inches)

(kHz)

(microseconds)

.050

66

5

.100

33

10

.200

16.5

20

.50

6.6

50

1.0

3.3

100

Drawing Number: 21109

Revision: NR