PAGE 9

SENSO

RS AN

D INS

TRUME

N

TATI

O

N F

O

R MAC

HINE

CON

DITI

ON M

ON

IT

ORIN

G

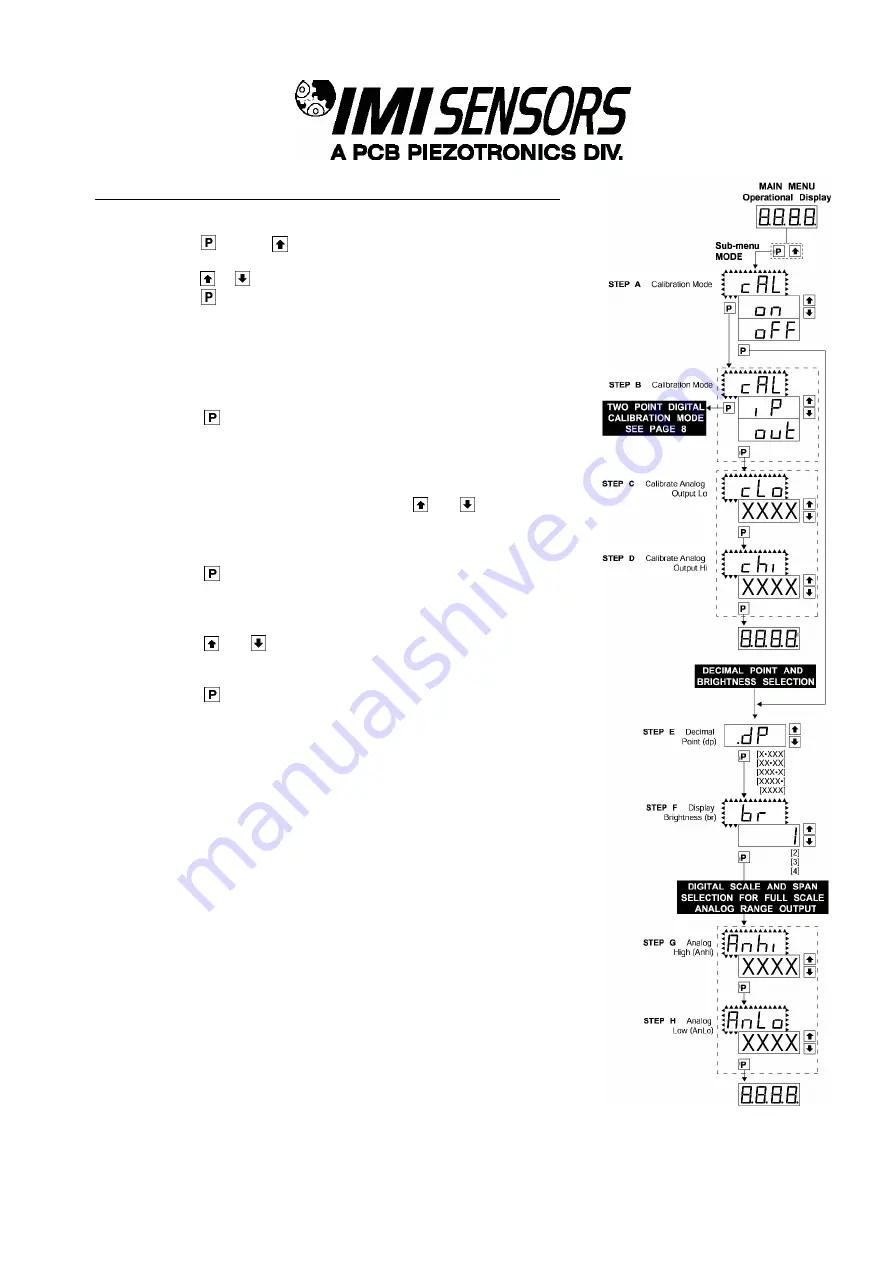

Two Point Analog Output Range Setting and Calibration

STEP A Enter the Calibration Mode

1) Press the

and the

buttons at the same time.

Display toggles between [cAL] and [oFF].

2) Press the

or

button. Display changes from [oFF] to [on].

1) Press the

button. Display toggles between [cAL] and [out].

Note:

If at this point the display skips directly to toggle between [oFFS] and the

previous [oFFS] setting, the software is detecting that the optional analog output

hardware is NOT installed.

STEP B Enter the Analog [oUT] Output Mode

1) Press the

button. Display toggles between [cLo] and internal scale

factor.

STEP C Set or Calibrate the [cLo] Low Analog Output Range

1) Connect a multimeter to pins 16 and 17 on the output module. See

Rear Panel Pinouts on Page 8). Using the

and

buttons, adjust

the analog output to the desired low value as shown on the

multimeter display. cLo may be adjusted to any value from

–

0.3mA to

17mA. (Factory Default is 4mA)

2) Press the

button. Display toggles between [cHi] and internal scale

factor.

STEP D Set or Calibrate the [cHi] Analog Output Range

1) Using the

and

buttons, adjust the analog output to the desired

high value as shown on the multimeter display. cHi may be adjusted

to any value from 17mA to 21mA. (Factory Default is 20mA)

2) Press the

button. The display exits the calibration mode and

returns to the operational display.

Note:

Having established the Low and High range of the analog output, the digital

span can now be selected which will set the two digital points between which the

analog output will occur. (See Digital Span selection next page).

Summary of Contents for IMI SENSORS 683A1

Page 30: ......