7

It is very important to perform maintenance on your turf foam marker before and after each use and at the end of each season of use.

Proper maintenance practices will help to guard against any breakdowns and allow for maximum performance.

Routine Maintenance

It is highly recommended that you perform routine maintenance on your turf foam marker before and after each use. Regular

maintenance practices should include:

•

A thorough inspection for any damage or wear.

•

Ensure that all hoses are attached and undamaged.

•

Ensure that the wiring harnesses are properly connected to each other and to an adequate power source.

The following are important components of the turf foam marker and their respective maintenance requirements.

a

b

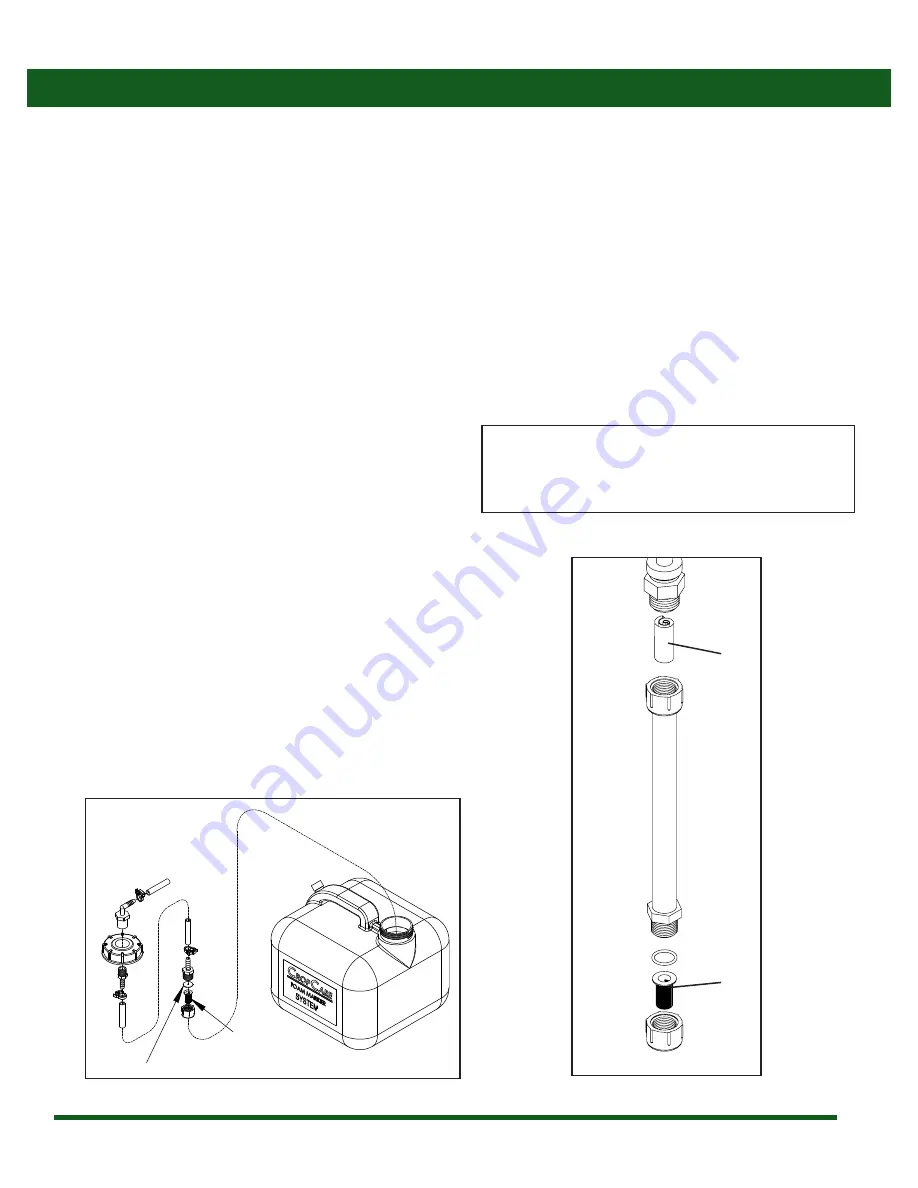

Figure 5: Foamer Tank Assembly

WARNING: Do not operate the turf foam marker

without the orifice disk. Operating the turf foam marker

without the proper orifice disk will result in damage to

the compressor and will void the warranty.

1. Liquid Strainer (a): The liquid strainer is located in the

foam solution tank on the end of the suction hose.

It should be rinsed after each use or on a daily basis

(Figure 5).

2. Orifice Disk (b): The orifice disk is located behind the

strainer on the end of the suction hose. Inspect the

orifice disk occasionally to ensure that there are no

debris or dirt plugging the disk’s circular hole (Figure 5).

3. Drop Tube Pads (c): Located inside the upper portion of

the drop tube assembly. It should be rinsed after each

use or on a daily basis (Figure 6).

4. Drop Tube Liquid Strainer (d): Located at the bottom of

the drop tube assembly. It should be rinsed after each

use or on a daily basis (Figure 6).

5. Compressor Motor Bearings: The motor bearings are

permanently lubricated ball bearings and do not require

additional oil.

Maintenance Instructions

Figure 6: Drop Tube Assembly

c

d

Summary of Contents for Accu-Ag AA25GFM

Page 13: ...13 Notes...