P-K Storm

TM

Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: October 2, 2019

Released: October 2, 2019

Patterson-Kelley 2019

All Rights Reserved.

2691000099 P-K Storm Installation and Owners

Manual.docx

Page 44

gas cock, 10012:

“Low Gas Limit”

will remain on the NURO display until the boiler is manually reset

by pressing “Reset Control”.

High Gas Pressure Switch

The boiler is furnished with a high gas pressure switch, installed near the boiler’s main gas

shutoff/control valve. The operation of this switch must be checked as follows:

1. Before starting the boiler, close the

downstream gas cock located inside the boiler’s enclosure.

2. Cycle the boiler on by generating a heat request.

3. Allow the boiler to proceed through prepurge and attempt ignition.

When the main gas shutoff/control valve opens to attempt ignition, the high gas pressure switch will trip,

causing the NURO touchscreen to display 10011:

“High Gas Limit”

. Even after re-opening the

downstream gas cock inside the boiler, 10011:

“High Gas Limit”

will remain on the NURO display until

the boiler is manually reset by pressing “Reset Control”.

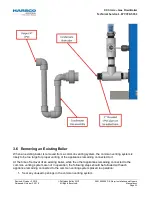

3.11 Fuel/Air Adjustments

The P-K Storm

™

boilers are equipped with a gas/air

ratio control valve and a gas safety shut off control

valve, combined into one valve assembly. The valve

functions in series with the variable speed combustion

blower to supply the correct gas/air mixture for

optimum firing performance and efficiency. The

combustion blower speed is controlled automatically

by the boiler controller. The blower speed determines

the amount of air flow and the amount of

suction/negative pressure at the gas valves. The gas

valve adjusts gas flow to maintain the proper delivery

pressure at the outlet of the valve.

Gas Pressure Adjustment

See rating plate for the minimum and maximum gas

pressure of the boiler. The supply pressure during

main burner operation must be greater than the

minimum indicated on the rating plate. Nominal gas supply pressure is 7” W.C. for natural gas. The

gas pressure must not exceed 14” W.C. which is the maximum allowable pressure on the gas train

components. Each boiler is furnished with a manual shut-off valve which has an integrated test port.

This port is located on the upstream side of the valve body for measuring supply pressure.

The air flow is pre-set at the factory prior to shipment. Gas flow is dependent primarily on fan speed

not upstream gas pressure. The automatic gas valve may have to be adjusted to obtain proper

combustion readings for specific local conditions. A combustion analyzer must be used. Combustion

must be set in accordance with Recommended Combustion Settings for P-K Storm Boilers in Section

3.11.2.

NOTE

Make sure to re-open the downstream gas cock (inside the boiler) after a successful test.

Gas Valve

NOTE

Make sure to re-open the main gas cock (external to the boiler) after a successful test.