MACH® Series

Gas-Fired Boiler

Installation

Page 14

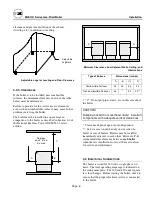

Pipe Capacity for Natural Gas

Equivalent Pipe Length

Maximum Capacity in Cubic Feet of Natural Gas per Hour

Pressure Drop of 0.5 inch Water Column/Equivalent Length of Pipe

(in feet)

Nominal

Iron Pipe

Size

(Inches)

Internal

Diameter

(Inches)

90º Ell

(Feet)

Tee

(Feet)

20

40

60

80

100

150

200

1/2

0.622

1.55

3.1

120

82

66

57

50

40

35

3/4

0.824

2.06

4.12

250

170

138

118

103

84

72

1

1.049

2.62

5.24

465

320

260

220

195

160

135

1- 1/4

1.380

3.45

6.9

950

660

530

460

400

325

280

1- 1/2

1.610

4.02

8.04

1460

990

810

690

620

500

430

2

2.067

5.17

10.3

2750

1900

1520

1300

1150

950

800

2- 1/2

2.469

6.16

12.3

4350

3000

2400

2050

1850

1500

1280

3

3.068

7.67

15.3

7700

5300

4300

3700

3250

2650

2280

4

4.026

10.1

20.2

15800

10900

8800

7500

6700

5500

4600

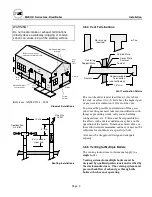

3.7.1 Gas Supply Piping by Installer

The boiler and all gas piping connections should be

pressure-tested and must be checked for leaks before

being placed into service. Test with compressed air or

inert gas if possible.

The boiler must be

disconnected at the boiler manual

shut-off valve (located at the end of the supplied gas

train) from the gas supply piping system during any

pressure testing of the system at pressures in excess of

1/2 psig (14" W.C.).

During any pressure testing of the gas supply piping

system at pressures equal to or less than 1/2 psig (14"

W.C.), the boiler should be isolated from the gas

supply piping system by closing the manual shut-off.

Some leak test solutions, including soap and water,

may cause corrosion. These solutions should be

rinsed-off with water after testing.

3.8

B

OILER

W

ATER

P

IPING

3.8.1 Piping Design

Water Flow in System

For proper water flow requirements see below.

Incorrect flow may result in eventual damage or

premature failure of the equipment.

MACH® Series 450

•

Max. Flow: 45 gpm

•

Min. Flow: 22 gpm (at max. firing rate)

MACH® Series 300

•

Max. Flow: 30 gpm

•

Min. Flow: 15 gpm (at max. firing rate)

Contact factory for minimum flow at other than

maximum firing rate.