7

Secur

e the rotor in a vice. Service

one hammer assembly at a time. Use

a ball peen hammer and pin punch to

remove the roll pins from each spacer

and shaft as shown.

(Discard the

roll pins. Use new pins during

reassembly.)

Pull out the shaft,

catching the spacers and hammers

with your free hand. Inspect the

shafts and spacers for unusual wear.

Replace them, if necessary.

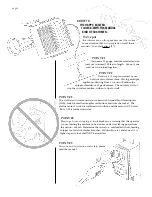

Reverse each worn hammer,

or replace them as need be. Note

how the Y-hammers are positioned in

relation to one another. Shafts with

two hammers must be reassembled

so that the bent prongs face inward;

the single hammers face their prongs

in opposite, outward directions.

Secure the spacers with new roll pins

using your ball peen hammer and

punch pin.

If not servicing the knives, r

eassemble

your unit by following 1 through 6 in

reverse order.

8

W

ith the chipper cone and base

removed, slowly turn the rotor clock-

wise with a probe until the chipper

knife appears in the hole. Scrape out

any pulp embedded in the heads of

the screws. Loosen the screws using

the 3/16” Allen wrench provided

with your unit. Unscrew them by

hand and remove the knife.

Sharpen the knife evenly at a 30°

angle. A homeowner’s bench grinder

with a fine grit stone will do. But

because the knife is specially heat-

treated, too much heat will make

brittle. So, grind only a little bit at a

time and allow them to cool.

Slow-speed, water-cooled grind-

ing is preferred. For best results, see

your local machine shop specialist.

The knife must be replaced once

the base of its cutting edge is ground

within 1/4” of the mounting holes.

Reassemble your chipper-shr

edder-vac by

following these instructions in reverse.

Sharpen the

chipping knife

when it loses

its self-feeding

action.

Minimum

distance = 1/4”

One hammer,

fork facing outwards.

One hammer,

fork facing in.

CORRECT

“STAGGERING”

OF HAMMERS

SHOWN HERE:

Removing the

knife without

disassembling

the housings.

page 15