13

GB

Switching off:

Release the ON / OFF switch

3

.

Setting the cutting angle

You can set the cutting angle accurately with the

help of the cutting angle scale

12 b

.

Release the wing screws / locking bolts of the

cutting angle preselector

9

on both sides, set

the desired angle on the cutting angle scale

12 b

and retighten the wing screws / locking bolts.

Setting the cutting depth

Note:

If possible we recommend that the cutting

depth is set approximately 3 mm greater than the

material thickness. This should help to ensure you

achieve a clean cut.

Release the wing screw on the cutting depth

setting clamp

5

, set the required cutting depth

on the scale

19

and retighten the wing screw.

Setting the guide fence

Release the wing screw

13

of the base plate

8

and insert the guide fence

15

into the slot

14

.

Retighten the wing screw

13

.

Switching the laser on and off

Switching on:

Move the laser ON / OFF switch

11

to setting “I”.

Switching off:

Move the laser ON / OFF switch

11

to setting “0”.

Note:

If the batteries are exhausted replace them

with two 1.5 V alkaline batteries LR44 (e.g. GPA 76).

Working with the circular saw

1. Switch on the device as described in the section

about “Switching on and off” and then place it

first with the front edge of the base plate

8

against the material.

2. Align the device using the guide fence

15

or

with reference to marked-out line or by using

the laser.

3. Hold the machine with both hands by the

handles (see Fig. A) and saw the material

with moderate pressure.

Setting the speed

Turn the wheel

1

to the desired speed setting

(arrow marking

)

(1 = lowest speed / 6 = highest speed):

Use the general settings suggested in the following

table (information offered without liability) or adjust

the speed setting on the setting wheel

1

to the

material being cut.

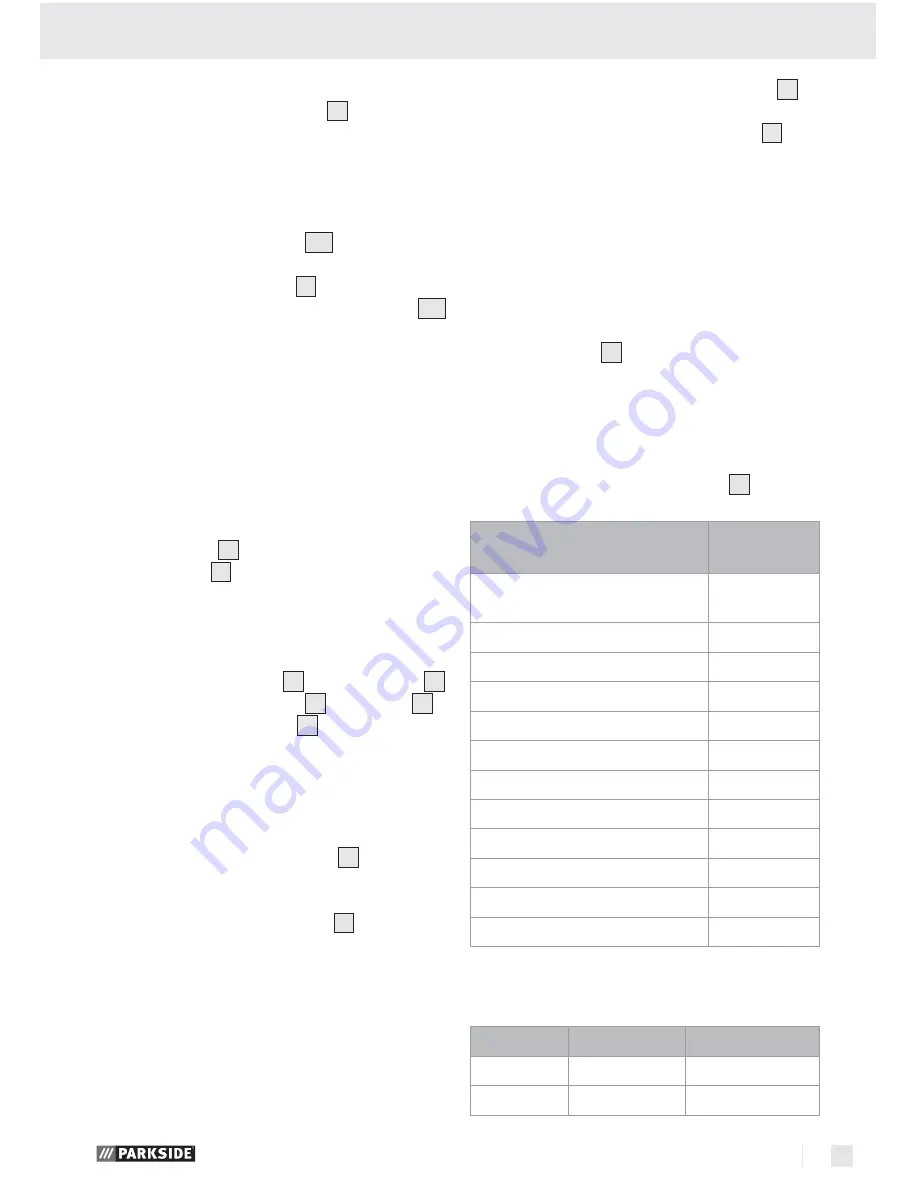

Material

Speed

setting

Hard- and softwood (solid wood)

cut longitudinally and transversely

6

Plywood, hard fibre board

6

Chipboard

6

Blockboard, laminated wood

6

Coated and veneered board

6

PVC board

3-5

Acrylic glass panels, Plexiglas

2-4

Aluminium board

4-6

Aluminium profiles

4-6

Plasterboard

1-2

Mineral wool board

1-2

Cement-bound chipboard

1-2

The circumferential speeds at minimum and maximum

rotational speeds are approx.:

Setting

Rpm

Metres/ sec

1

2,200

21.8

6

5,200

51.7

Preparing for use