PDWS 125 A1

GB

│

CY

│

11

■

Operation

Operating a compressed air tool

NOTE

►

In order to achieve the full power available

from your compressed air tool, always

use compressed air hoses with an internal

diameter of at least 9 mm. A lower internal

diameter can considerably reduce the power.

CAUTION!

►

Do not use a compressed air line that con-

tains any water condensation.

►

The tool must be sufficiently supplied with

pneumatic oil to ensure long service life. This

can take place as follows:

–

Use oiled compressed air by fitting a mist

lubricator.

–

Without a mist lubricator: add oil manu-

ally through the compressed air connec-

tion every day. Approx. 3-5 drops

of pneumatic oil for every 15 operating

minutes during continuous use.

►

If the tool has been out of operation for sev-

eral days, add around 5 drops of pneumatic

oil manually through the compressed air

connection .

►

Allow the tool to run at idling speed for a

short time.

►

Always guide the machine using both hands.

►

Switch on first, then apply the accessory tool

to the workpiece.

►

After switching off, only put the machine down

once the motor has come to a standstill.

♦

1.) Attach a suitable accessory tool.

♦

2.) Adjust the operating pressure (measured

at the air intake when the compressed air

tool has been switched on). Please refer to

the section entitled "Technical data" for the

maximum permissible operating pressure

♦

3.) Connect the compressed air tool to the com-

pressed air supply.

♦

4.) Switching on: Push the safety lock-out

towards and press the ON/OFF switch .

♦

5.) Switching off: Release the ON/OFF switch .

Working procedures

Sanding:

♦

Press the machine against the workpiece moder-

ately and move it backwards and forwards over

the surface so that the workpiece surface does

not become too hot.

Rough grinding:

♦

Work using an angle of incidence of between

30° and 40° for good working results.

NOTE

►

Never use cutting discs for rough grinding.

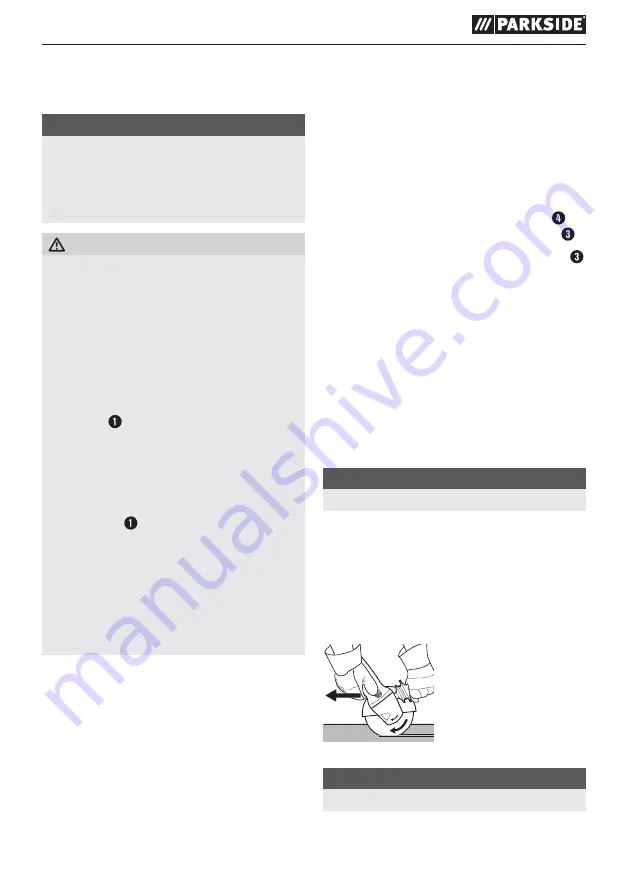

Abrasive cutting:

♦

Always work against abrasive cutting (see Fig-

ure 3). Otherwise there is a risk that the ma-

chine can jump out of the cut in an uncontrolled

manner. Work using moderate forward speed

appropriate to the material being processed.

Do not tilt, do not press, do not oscillate.

Fig. 3

NOTE

►

Never use rough grinding discs for cutting.

Summary of Contents for 276009

Page 3: ......

Page 17: ... 14 GB CY PDWS 125 A1 ...

Page 31: ... 28 RO PDWS 125 A1 ...

Page 45: ...PDWS 125 A1 42 BG ...

Page 59: ... 56 DE AT CH PDWS 125 A1 ...