Chapter 4: Maintaining the Monitor

Performing Internal Maintenance

PHM/PM User Guide

4-4

cables from the end located on both the backshell boards.

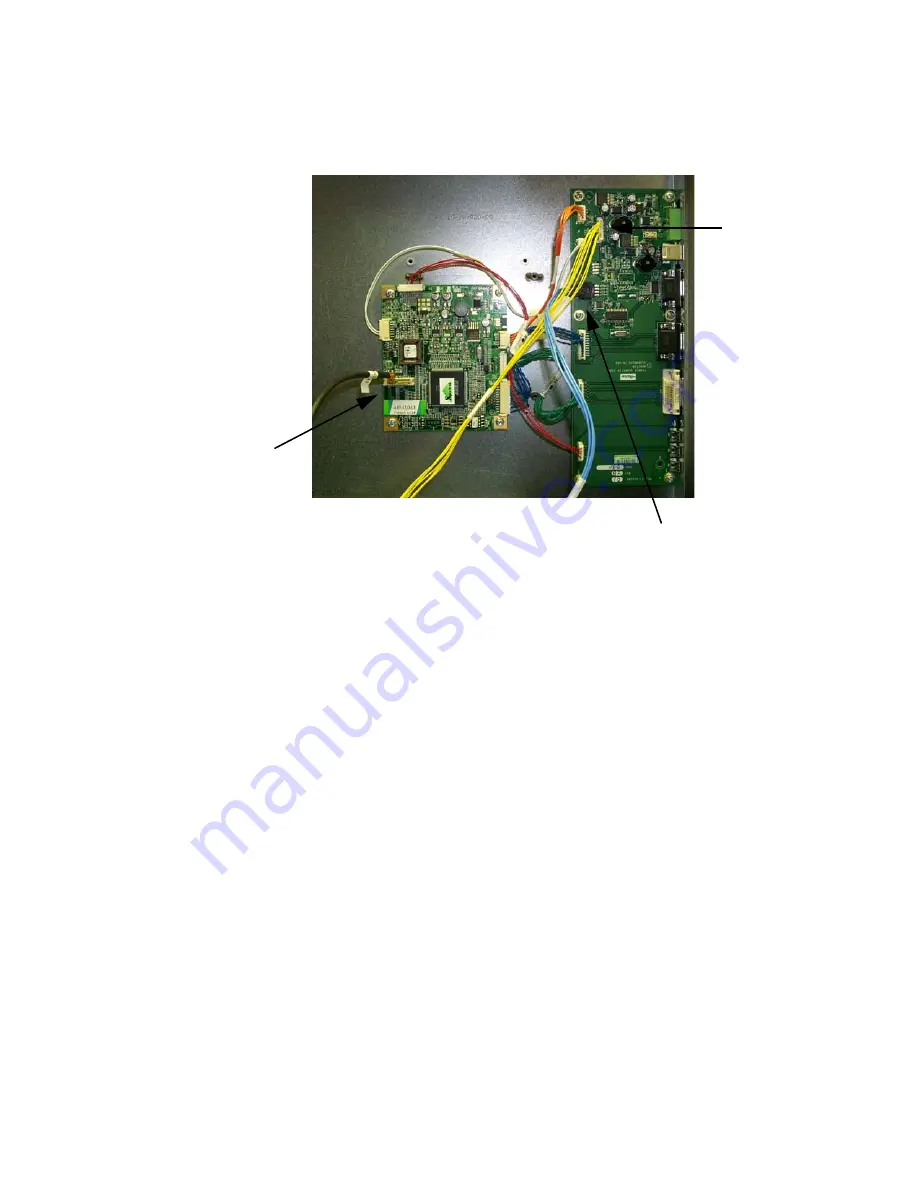

Figure 4-2: Accessing the Internal Cables of the Monitor

10

Once the cables are disconnected, gently lift the backshell off the

unit.

11

Proceed to the specific maintenance or troubleshooting procedures

you need to perform.

Closing the Backshell

1

Carefully connect the touchscreen, display and inverter board cables

to their respective connectors (see Figure 4-2). Be sure you orient

the cables so that you do not bend their pins.

2

Secure the backshell to the unit using the retaining screws or nuts

removed earlier. There are 12 retaining screws on 15" units and 16

retaining nuts on 17" units.

3

Reinstall the unit in its enclosure or on its arm.

4

Reattach the power input cable, touchscreen cable, video input cable

and the ground cable at the left side of the monitor.

5

Reconnect the monitor to a power source.

6

Turn on the computer and the monitor.

Display cable

Touchscreen cable

Inverter

cable