Refrigerating Specialties Division

3

Disassembly and Assembly

Refer to the exploded views (Fig. 2) for the parts discussed in this section.

Before disassembling or assembling an A2 regulator read the information

in this bulletin and Bulletin RSB, Safety Procedures for R/S Refrigeration

Control Valves.

Before a regulator Is removed from the line or disassembled in the line,

make sure that all refrigerant has been removed from the regulator

(including the bonnet where applicable), and the regulator is isolated from

the rest of the system in a safe manner.

All A2 Regulators, General Procedure

Disassembly

– Remove Seal Cap 1 and back out the Adjusting Stem 6 to

remove all tension from the Range Spring 13. This is necessary to avoid

possible damage to internal parts of the regulator. Remove Bonnet Screws

11 and disassemble parts 12 through 18 as shown in Fig. 2. Normally

parts 3 through 6 do not require disassembly. Inspect parts for dirt,

corrosion and wear and clean or replace as needed. Gaskets and “O”

rings should be replaced whenever a regulator is re-assembled.

Assembly

– When assembling the regulator, lightly oil the gaskets with

refrigerant oil. Do not apply oil to the “O” rings because some oils may

cause slight swelling and diameter increase. This does not affect the

performance of the “O” rings, but it may make the assembly difficult. Make

sure all parts are free of dirt and moisture condensate. Dry the parts if

necessary and oil lightly.

All gaskets and “O” rings must be properly aligned. Arrange the parts as

shown in Fig. 2 making sure that the Diaphragm Follower 15 is properly

located in the Bonnet 8. The diaphragm must be installed with the raised

center portion towards the bonnet. Make sure two diaphragms are used

for A2B and A2BO Range D and A2A Ranges A and D. Tighten the Bonnet

Screws 11 gradually and evenly. The screws should be tightened by turning

opposing screws alternately rather than in a circular pattern. The ideal

tightening torque is 1.5 kg-m (11 lbs.-ft.).

After the regulator is assembled and re-installed, check all external joints

for leaks. Adjust the regulator spring to the proper set point by turning the

adjusting stem while observing the proper pressure gauges during system

operation.

A2B and A2A

After above General Procedure for disassembly, inspect the Valve Seat

19 top seating surface for dirt, wear or damage. Remove from valve body

and clean, lap on a flat plate or replace as necessary. Examine the

diaphragm region which contacts the seat surface; look for dirt, heavy

scratches or corrosion. If the diaphragm cannot be easily wiped clean, it

should be replaced.

A2BO and A2BOE

After above General Procedure for disassembly, remove Bottom Cap 27.

Disassemble the Valve Plug 25 and Spring 23 by inserting a screwdriver

in the slot in the bottom of the valve plug and turning the hexagon Spring

Nut 22 with a wrench. Inspect the valve plug and the matching seat surface

in the Valve Body 20 for dirt, corrosion or damage. Clean, lap in place or

replace as needed. Assemble new “O” ring 26 to the valve plug on A2BOE

only (no “O” ring 26 required on A2BO), and carefully insert the assembly

into the valve body. Place Spring 23 in place and tighten the Spring Nut

22 with a wrench while inserting a screwdriver into Valve Plug 25. Replace

Bottom Plug “O” ring 28 and screw bottom cap in place.

A2BP

For this regulator, which has an external connection to the bonnet, check

the parts inside the bonnet for dirt, moisture or corrosion, especially on

the outside diameter of diaphragm follower. If source of dirt, moisture or

corrosion cannot be eliminated, it may be advisable to install and maintain

a filter-drier in the sensing line to the bonnet.

SERVICE POINTERS

SYMPTOM-Regulator does not shut off flow

PROBABLE REASON

CORRECTION

Incorrect setting .......................................................... Adjust set point as needed.

See appropriate adjustment

procedure.

Wrong pressure range ............................................... Check pressure range,

change range spring if necessary

Diaphragm or seat dirty, damaged or frozen ............ Clean or replace – clean strainer

Diaphragm follower stuck or damaged ...................... Clean or replace.

Install follower carefully

A2BO plug sticking ..................................................... Check for dirt, corrosion or

damage.

Clean or replace. Check mating bore

and seat in valve body.

A2BO plug and seat eroded due to flash gas ........... Replace as needed. Reduce flash

gas by sub-cooling or by reducing

pressure drop across valve by

providing restriction at valve outlet.

A2BO diaphragm ruptured or badly deformed ......... Replace. Make sure Range “D” has 2

diaphragms.

SYMPTOM – Regulator does not open

Incorrect setting .......................................................... Adjust set point as needed.

See appropriate adjustment

procedure.

Wrong pressure range ............................................... Check pressure range,

change range spring if necessary

Diaphragm follower stuck, damaged or frozen ......... Clean or replace.

Install follower carefully

A2B or A2A diaphragm ruptured or badly deformed Replace. Make sure Range “D” has 2

diaphragms.

A2BO plug sticking ..................................................... Check for dirt, corrosion or

damage.

Clean or replace. Check mating bore

and seat in valve body.

SYMPTOM – Regulator operation erratic

Diaphragm or seat dirty or damaged ........................ Clean or replace – clean strainer

A2BO plug sticking ..................................................... Check for dirt, corrosion or damage.

Clean or replace. Check mating bore

and seat in valve body.

Diaphragm follower has burrs or dirt on outside

diameter ...................................................................... Clean or replace.

Check other system components .............................. Adjust or replace as needed.

SYMPTOM – Presure drop across valve too high

Inlet or outlet restricted .............................................. Check for restriction. Clean strainer.

Valve too small ............................................................ Replace with proper size valve.

Large amount of flash gas in a liquid line ................. Reduce flash gas by subcooling.

Reduce line restriction by increasing

pipe size, particularly at the valve

outlet.

Replace with larger valve.

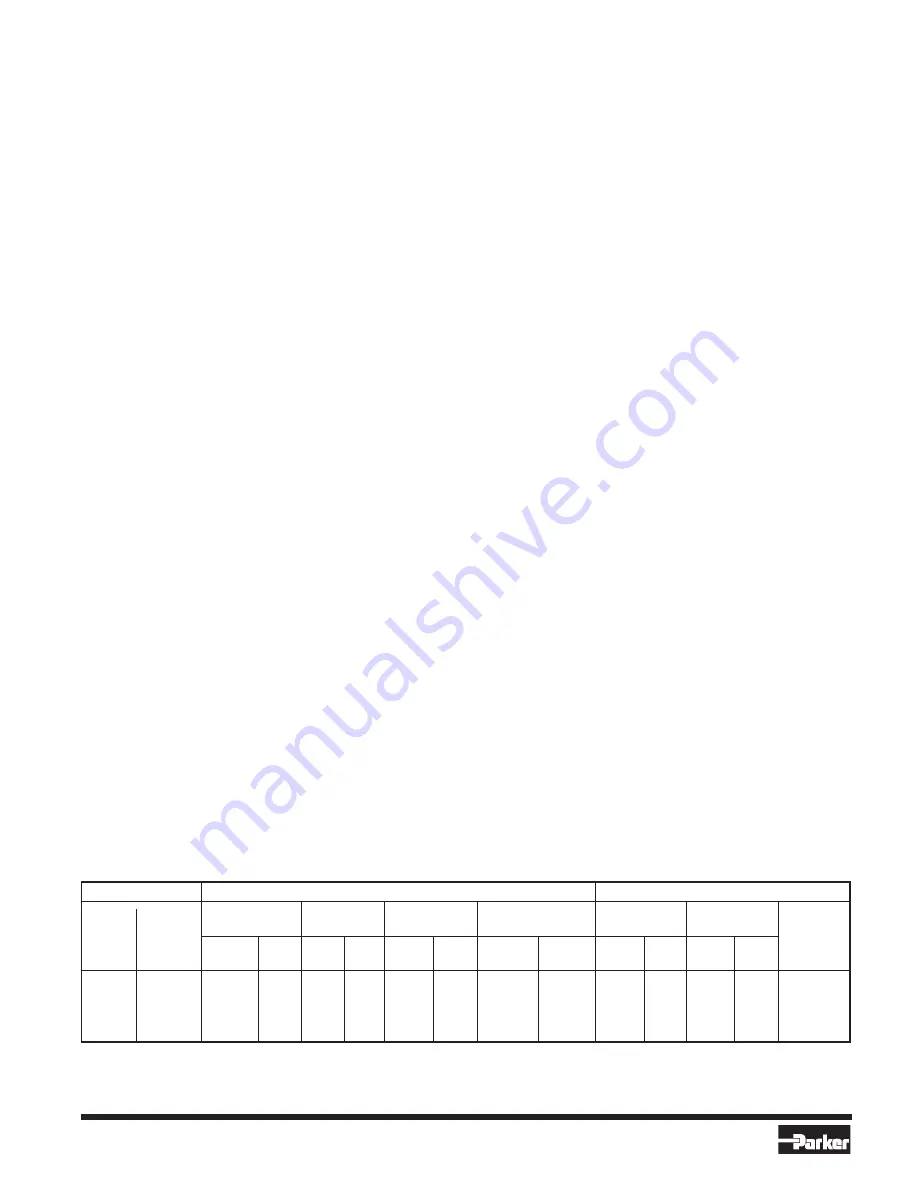

FLANGE TABLE

À

FPT FLANGES

WELDING FLANGES

Ã

O.D.S. FLANGES

Fit Pipe

Socket Weld

Weld Neck

Flange

Tubing

Fitting

Nominal

Size

Socket I.D.

Neck O.D.

Package No.

O.D.

I.D.

Pipe

Flange

Flange

Size

Package

Nominal

O.D.

Á

Socket

Weld

Â

Package

Inches

No.

Inches

mm

Inches

mm

Inches

min

Weld

Neck

Inches

mm

Inches

mm

No.

1/4

200000

1/4

13.25

.560

14.22

.540

13.72

200004

200008

3/8

200001

3/8

16.75

.695

17.65

.675

17.15

200005

200009

1/2

12.70

.502

12.75

200012

1/2

200002

1/2

21.25

.860

21.84

.840

21.34

200006

200010

5/8

15.87

.627

15.92

200013

3/4

200003

3/4

26.75

1.070

27.18

1.050

26.67

200007

200011

7/8

22.22

.877

22.27

200014

À

FPT – Internal NPT (USA Standard Taper Pipe Thread)

Á

Metric steel tubing used for refrigeration

Â

Metric copper tubing used for refrigeration

Ã

ODS Connections to fit copper tubing of given outside diameter

DEFINITIONS: O.D.S. – Outside Diameter Sweat; I.D. – Inside Diameter; O.D. – Outside Diameter

When ordering flanges, use the proper package number from Flange Table. A Flange Package consists of two flanges only.