Bulletin MSG30-3245-INST/UK

Installation Manual

9

Parker Hannifin

Pump & Motor Division Europe

Chemnitz, Germany

Axial Piston Pump

Series PV, series 44 and higher

The length of the load sensing line can be up to 15

m. If the line is longer than 5 m it has to be consid-

ered, that low environmental temperatures and high

fluid viscosity can have a negative influence to the

compensator performance.

The line should be designed to avoid any significant

pressure drop.

Factory setting for the load sensing pressure differ-

ential is 10 bar ± 1 bar. This adjustment should only

be changed in exceptional cases.

The adjustment is possible by turning the pilot valve

housing after loosening the lock nut.

Please refer to the setting instructions on page 7.

All compensators described in chapters 3 - 6 can

be shipped with a directional control valve for stand-

by operation (compensator codes ends with..W) or

with a proportional pilot valve for electrical pressure

adjustment (compensator code ends with ..K)

Compensator code ...MMW with directional control

valve code D1VW2K*JW for stand-by operation

(24 VDC, normally open)

Compensator code ...MMK with proportional pres-

sure pilto valve code PVACRES-*35

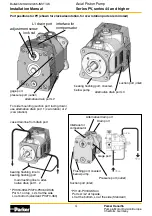

8. Two spool load sensing compensa-

tor, codes ...MTP and ...MTK

interface NG6, DIN24 340 for pilot valve

pressure control stage

load sensing port

flow control stage

The two spool compensator, code ...MT* has two

separate compensator valves for flow (load sensing)

and pressure compensation.

That results in a steeper pressure compensation

curve, which can be beneficial in certain applications.

The flow control stage has no integrated pilot valve,

because this would eliminate the effect of the two

spool control. The pressure stage has no integrated

pilot valve, because during flow control the T port of

the pressure compensator is under control pressure.

This would prevent the pilot valve from opening.

With the adapter kit PVCMCK.. the pressure com-

pensator can be made remote controlled.

On the topside interface any pressure pilot valve can

be mounted. See chapter 3 for requirements.

The factory setting of the flow compensator is

10 ± 1 bar, the adjustment for the pressure com-

pensator is 15 ± 1 bar. These adjustments should

not be modified.

If different adjustments are required by the system or

by the load sensing valves used in the system, see

page 7 for setting instructions.

With ordering code ...MTP a manual adjustable pres-

sure pilot valve code PVAC1PM*S35 is mounted on

the elbow manifold.

With ordering code ...MTK a proportional pilot valve

code PVACRES-*35 is mounted on top. For electronic

pressure control a suitable power amplifier is re-

quired. We recommend the digital modules PCD00...

supplied by Parker HCD.

Because the two spool compensator has no in-

tegrated pilot valves, for a stand-by function the

compensator accessory PVAC1EM*C**35, includ-

ing a directional control valve and a pilot section,

is required.