6

M

AINTENANCE

S

AFETY

P

RECAUTIONS

1. Refer to Maintenance Schedule label on the machine as well as this manual for when to

perform maintenance.

2. Check the function of your machine DAILY by verifying the following:

• Inspect cables and end fittings for any signs of wear. Replace if worn, frayed or

damaged with original Paramount replacement components.

• Verify that all adjustments are possible and carried out with ease. Make sure that

each adjustment pin inserts completely into each position without binding.

• Verify that safety catches and stops are in proper working order and engaged.

• Verify that the exercise is performed smoothly, free of noise and/or binding.

• If equipped with a weight stack, verify that the proper weight selector pin is in place.

3. Check the function of your machine WEEKLY by verifying the following:

• Nuts, Bolts, and Fasteners: Check tightness weekly. If any hardware has become

loose, retighten and/or use Loctite

™

Threadlocker 242.

• Frames and Lifting Arms: Inspect weekly for integrity and function. Replace any

component at first signs of wear. Use only Paramount supplied components.

4. Replace any warning label at first sign of wear. Labels and the Facility Safety Sign may be

obtained from Paramount free of charge.

B

OLT

L

ENGTH

M

EASURING

G

UIDE

S

AFETY

FLAT HEAD SCREW

BUTTON HEAD SCREW

HEX HEAD SCREW

SOCKET HEAD SCREW

1

2

3

4

5

Summary of Contents for FS-51

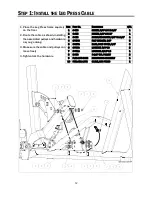

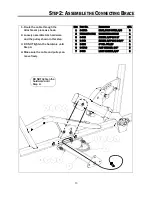

Page 1: ...FS 51 LEG PRESS ASSEMBLY MANUAL AM FS51 010913...

Page 31: ......