ー 30 ー

ー 31 ー

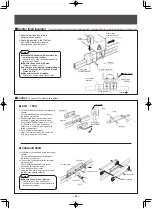

Mounting an end tension insulator to a terminal plate

Tightening the Tro-Reel unit

Pull the Tro-Reel unit tight and tighten the end tension insulator nut snugly.

●

Length of coil spring

●

After completing installation, run the hoist or crane

ten or more times and reconfirm the spring tightening

length.

Failure to do so may cause poor collector arm contact or

separation from wires.

●

After installation, let the hoist and crane travel for

more than 10 times and recheck the tightness of

spring. If this job is not properly done, bad contact or

detailing of collector arm may occur.

1.Insert the terminal plate into the groove of insulator.

2.Mount the cover to the insulator.

Cover

Special washer

Insulator

Insulator

Insert into the

groove.

Terminal plate

End tension insulator bracket

End tension insulator

Nut

bolt

(

M12

)

I-beam

L

Coil spring

Tro-Reel unit

10

℃

or lower

11

〜

40

℃

Ambient temperature

during installation

115mm

125mm

L

2254

1568

Tension

(N)

6

7

Feeding power to the Tro-Reel

Power can be fed from the line end via an end tension insulator.

Connect the power wire to the terminal plate

using a crimp-on terminal.

Applicable crimp-on terminals: _<50mm

2

(60A, 150A)

_<100mm

2

(200A)

_<150mm

2

or 100mm

2

×

(300A)

Crimp-on terminals are not included.

End tension insulator

Terminal plate

Cover

Crimp-on terminal

(not included)

Terminal screw

(

M-8

)

8

Terminal screws must be securely tightened.

Failure to do so may cause fire.

Caution

Notes

●

Be sure to mount the special washer.

Failure to do so may cause damage of the insulator.

Notes

●

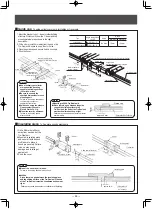

Set the distance from the bottom surface of the Tro-reel conductor to the

center ofthe collector arm mount rod (not included) to 95mm (in the

center of the conductor cleraner mounting tolerance movable range

95±20mm)

●

Arm must be attached parallel to the Tro-Reel unit without any twisting.

■

Standard installation

●

Two collector arms should be used together (tandem type) for circuit

separation and line swiching, and especially in applications in which it is

imperative that collector arms not be separated from wires. Tandem

collector arms cannot be used horizontally. For horizontal installations,

use a single-type collector arm.

■

Assembly in tandem configuration

●

Collector shoes should be replaced when they

partially wear down to the replacement indication line.

Please exchange the collector shoes ahead of time

when it will be worn out to the replacement indication

line by the time of the next check.

■

Collector shoe replacement

●

As shown in a figure,mounted collector arm support parts for transverse

on base of the collector arm.

Tightening torque of fixing screws

:

0.98 N

・

m

〜

1.32 N

・

m

●

Set the distance from the bottom surface of the Tro-reel conductor to the

center ofthe collector arm mount rod (not included) to 95mm (in the center

of the conductor cleraner mounting tolerance movable range 95±20mm)

■

Horizontal installation

Replacement line

Collector shoe

Bolt

Bolt

Bolt

Bolt

●

After installation, be sure that the hanger, the Tro-Reel unit and the collector arm are level. Failure to do so may

cause poor collector arm contact.

●

When you want to use the collector arms with centerring horizontally,please contact Panasonic electric Works,Ltd.

●

In a horizontal ways case, be sure to use the horizontal support parts.

Failure,there is a risk of derailment or loose arms collector.

●

Distance to the center of the collector arm from the center of the duct

Notes

Tro-Reel unit

Collector arm

Collector arm mount rod, 25

×

25mm

(not included)

95

±

20mm

(movable area)

Fixing screw

Base

Collector arm support

parts for transverse

95

±

20mm

Tro-Reel unit

Collector arm

Collector arm

mount rod

(not included)

(movable area)

How to mount collector arms

9

110mm

70mm

■

Horizontal installation with its opening

facing into tandem-type

■

Wire clamp

Give slack to a lead.(Lead is a fixed position,

430mm from the base of collector)

Do not affect a collector's run.

(M4×8

)

Push here.

430mm

When collector arm mount rod set up a reference

position,

the operating range from 70mm

〜

110mm of collector arm set up to be twisting.

Adjust the arm mount rod between the High-Tro-Reel unit to become 110mm

or less and 70mm or more at the center between hangers, and 70mm or more

at the bracket.

Lead

Collector arm

Collector arm mount rod

Fixing screw

Collector arm

support parts

for transverse

Collector arm

support parts

for transverse

Use range of movable

A

A

Distance to the center of the collector arm

from the center of the duct

Dimension A of permitted

movable range

Distance to the center of the collector arm

from the center of the duct

Give slack to a lead.

Cable clamp

Use the horizontal support parts

5mm

Not use the horizontal support parts 15mm

●

Mounting the horizontal support parts in both the collector arms