20

8.1.2.

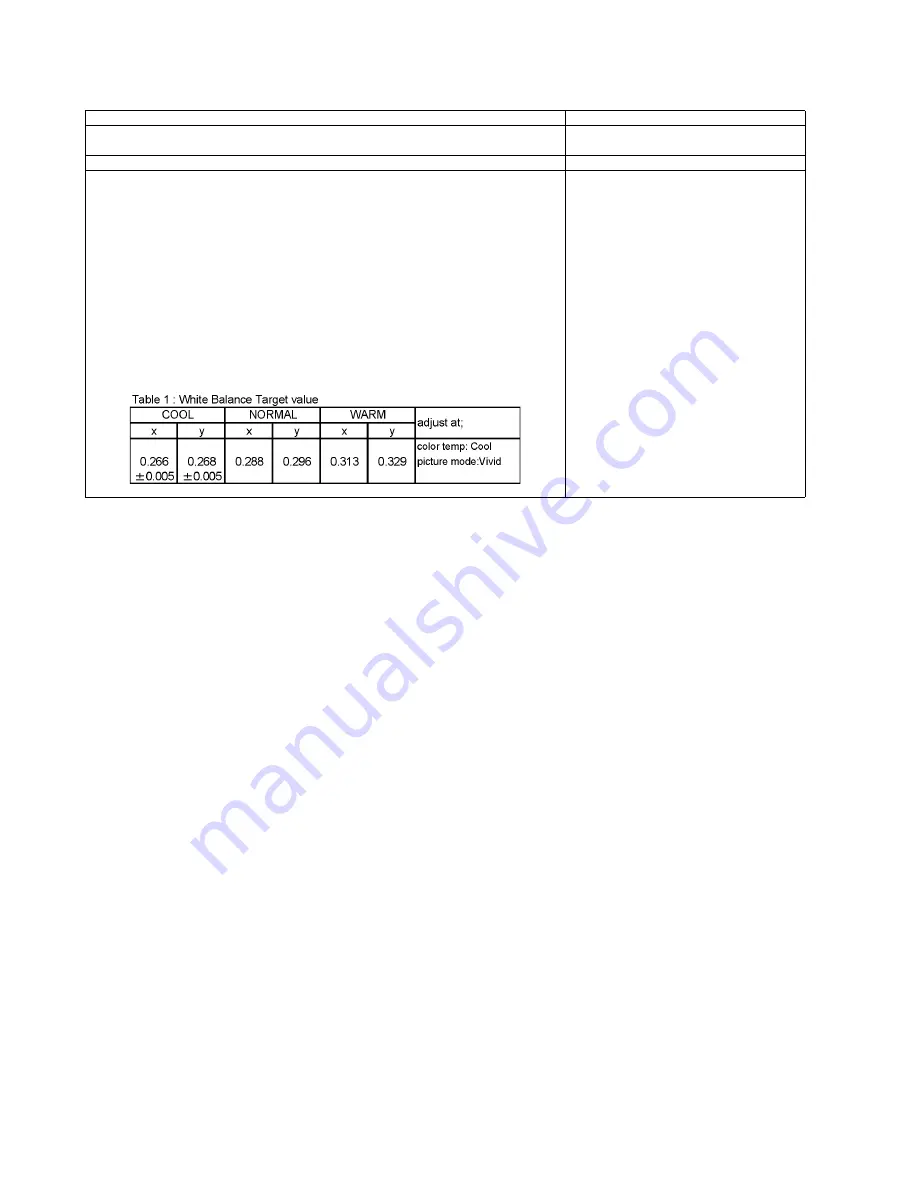

White balance adjustment

Name of measuring instrument

Remarks

Color analyzer

(Minolta CS-1000 or equivalent)

Procedure

Remarks

1. Enter the Service mode.

2. Receive the Analog-RF (except for no signal) or set CVBS/YUV/HDMI (no signal is

available).

3. Select [WB-ADJ] by using [1] and [2] key in the remote controller.

4. Check that the color temp and the picture mode is the values written in table1.

5. [INNER PATTERN] is displayed by using [5] key by using [5] key in the remote controller.

6. Select [G-CUTOFF] by using the [3] and [4] key in the remote controller, and set the value

to [80] by using the volume [+] and [-] key.

Also, [B-CUTOFF] and [R-CUTOFF] set to [80]

7. Set [G-DRIVE] value to the initial data (ex. D0).

8. Set the color analyzer and adjust color point to the values written in table1 by using [B-

DRIVE] and [R-DRIVE]

9. Increase RGB-DRIVE value so that the maximum drive value of one of R-DRIVE or G-

DRIVE or B-DRIVE should become [FF]

([ALL-DRIVE] set to [FF].)

Summary of Contents for TC-P42X60

Page 17: ...17 7 2 17 EMI processing...

Page 18: ...18...

Page 27: ...27 10 3 Wiring 2...

Page 28: ...28 10 4 Wiring 3...

Page 29: ...29 10 5 Wiring 4...