9

USING THIS PRODUCT AS A SAFETY EQUIP-

MENT FOR A PRESS MACHINE IN JAPAN

When using this product as a safety equipment for a press machine in

Japan, this product's installation, electrical wiring, inspection and mainte-

nance must be completed by a “qualified personnel.”

Qualified personnel refers to a press work supervisor, or other work

supervisor who has completed special training as set forth by Industrial

Safety and Health Laws, and has extensive knowledge and experience

to resolve problems and any problems related to his / her duties.

●

When used in combination with

SF4B-□-01<V2>

, this product satisfies

the “Model Examination” as set forth in the Japanese Industrial Safety

and Health Laws Provision 44-2 as indicated below.

[When using in combination with SF4B-□-01<V2>]

•

Model examination No.:

No. TA527 (

SF4B-A□-01<V2>

)

No. TA528 (

SF4B-F□-01<V2>

,

SF4B-H□-01<V2>

)

•

Conforming standards:

Standards for press machine or shear safety equipment structure

(Ministry of Labor Notice No. 102, issued September 21, 1978)

●

When using

SF4B-□-01<V2>

and this product as safety equipments for

a press machine in Japan, a pre-work inspection and periodic inspec-

tion must be carried out by the press machine work supervisor or by

the person in charge of the matters listed in Provision 134, No. 1, 2 and

4 of the Ordinance on Labor Safety and Hygiene. The press machine

work supervisor, etc., must inspect the following matters before starting

work, and must record and save the results.

Emitter of SF4B-□-01<V2>

□ Security of mounting

□

Adequacy of mounting position (safety distance and vertical position)

□ Presence of damage

□ Presence of abnormality in external wires

□ Presence of contamination on emitter

□ Security of detection state

Receiver of SF4B-□-01<V2>

□ Security of mounting

□

Adequacy of mounting position (safety distance and vertical position)

□ Presence of damage

□ Presence of abnormality in external wires

□ Presence of contamination on receiver

□ Security of detection state

Control unit SF-C13

□ External wiring

□ Indicators

□ Presence of abnormal operation with switches, etc.

□ Security of mounting

Refer to “Policy on Press Machine Safety Equipment Control” (Ministry

of Labor, Basic Publication No. 446-2, issued on July 9, 1993) for details.

●

Compatible press machines

•

When using this product as a safety equipment for a press machine

in Japan, the machine in which

SF4B-□-01<V2>

and this product are

mounted must be capable of suddenly stopping from any operation

point even during the operation cycle. Do not use

SF4B-□-01<V2>

and

this product with a machine having an irregular sudden stop.

•

Do not use this product with a power press having a full-rotation clutch.

•

When using this product as a safety equipment for a press machine in

Japan, do not use the product with a press machine that does not sat-

isfy the following specifications.

Item

Specifications

Model

Press machine having sudden stop device and restart

prevention mechanism

Pressure capacity

50,000kN or less

Sudden stop time

500ms or less

Stroke length

Within (Protective height - Die height)

Range of model height

Within bolster width

10

TROUBLESHOOTING

●

The number of times the fault indicator (yellow) blinks indicates the

type of error state, as follows.

Blinking

Description of error

Cause / Remedy

2 times

Internal relay contact is

weld

The contact was weld due to the lifetime of the

relay.

Replace this product by new one.

3 times

Reset mode error

Wiring of the terminal X1, X2 or X3 is not correct.

Check if the wiring has been correctly done.

4 times

or more

I n f l u e n c e o f n o i s e /

power supply or internal

circuit failure

Check the noise environment.

Check the wiring, power supply voltage and

voltage capacity.

●

Make sure that this product and the light curtain are connected to the

common power supply.

●

When the sensor doesn't operate properly even if the remedies de-

scribed above are taken, contact our office.

●

Interval of blinking for the fault indicator (yellow) is approx. 0.6 sec.

Check the number of times the indicator blinks for approx. 2 sec. from

the indicator “OFF” period.

WARNING

Install a RESET switch in palace where it is possible to see all over the

dangerous zone and outside of the zone.

<Manual reset>

• In case of the manual reset, configure the back check circuit between X1

and X2. If it is not necessary to check KA and KB, short-circuit KA and KB.

•

Do not connect anything to X3.

•

The unit operates by the trailing operation of the external reset button.

•

Two or more units cannot be controlled by an external reset button.

Prepare the external reset button for unit by unit.

X1

RESET

KA

KB

X2

<Auto reset>

• In case of the auto reset, configure the back check circuit between X1 and X3.

If it is not necessary to check KA and KB, short-circuit between X1 and X3.

•

Do not connect anything to X2.

•

Avoid auto-reset of the system after emergency stop by using the other

control circuit. (IEC / EN 60204-1 part 9.2.5.4.2 and 10.8.3)

X1

KA

KB

X3

●

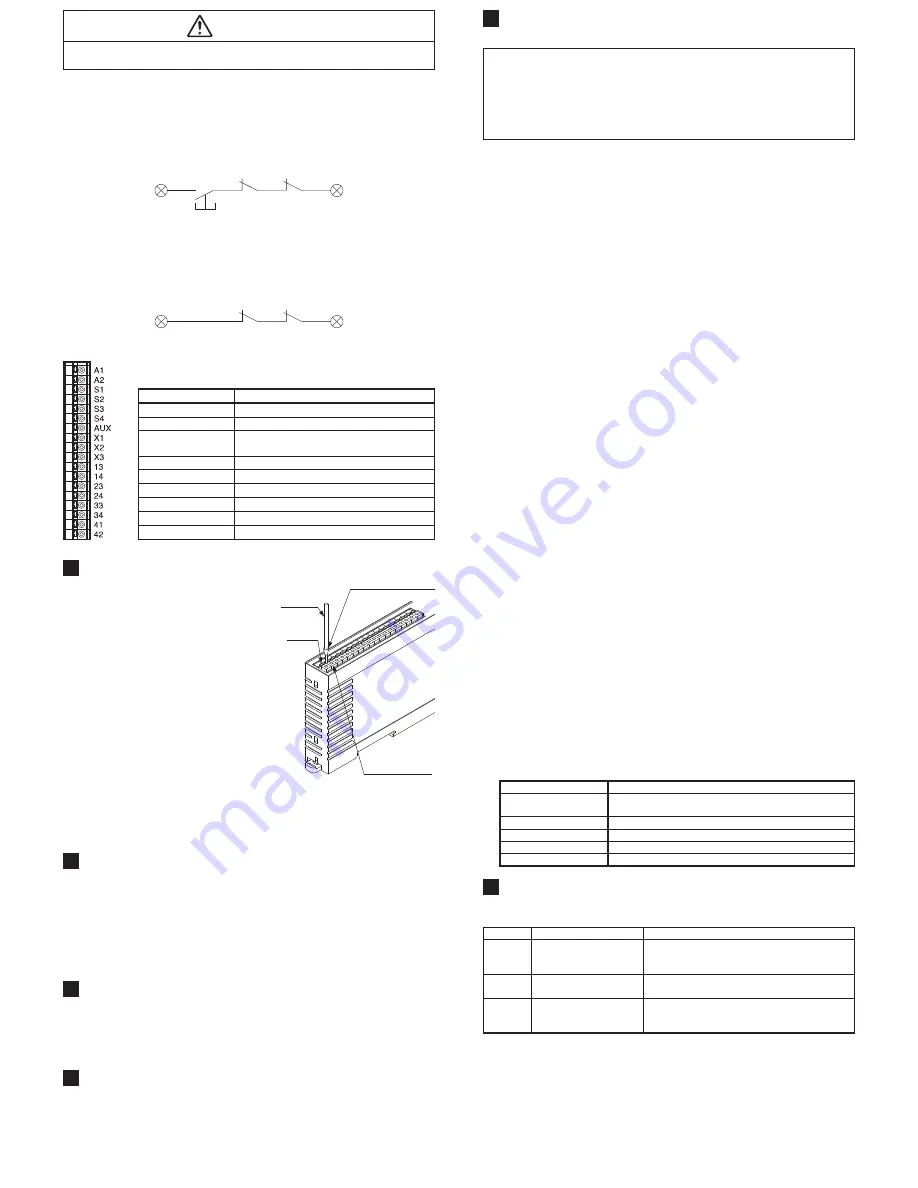

Terminal arrangement diagram

Terminal No.

Description

A1

24V DC

A2

0V

S1 to S4

Light curtain control output (OSSD) input

terminal

AUX

Semiconductor auxiliary output

X1

Reset output terminal

X2

Reset input terminal (manual)

X3

Reset input terminal (automatic)

13-14, 23-24, 33-34

Safety output (NO contact × 3)

41-42

Auxiliary output (NC contact × 1)

5

MOUNTING TERMINAL BLOCK

●

When connecting to the terminal

block, insert a solid wire or twisted

wire (lead wire) with a ferrule (sleeve)

terminal (please arrange separately)

into the hole till it stops as shown in

the figure right. The wire is locked

when it is properly inserted. However,

do not to pull the wire with excessive

force, as this can cause a cable break.

●

When connecting the twisted wire (lead wire)

without a ferrule (sleeve) terminal, insert the

wire to the innermost of the connecting hole

while pressing the release button.

●

When releasing the solid wire or the

twisted wire (lead wire), pull the wire

while pressing the release button.

Lead wire

Release

button

Solid wire or twisted

wire (lead wire) inlet

Ferrule (sleeve) terminal

(Please arrange separately)

●

The following solid wire and twisted wire (lead wire) are recommended.

Solid wire: ø0.4 to ø1.2mm (AWG 26 to 16)

Twisted wire (lead wire): 0.2 to 1.25mm

2

(AWG 24 to 16)

Standard stripped wire length: 11mm

6

SHORT-CIRCUIT PROTECTION

●

The power supply unit of this equipment adopts the electronic fuse

which do not require any replacement.

●

When the electronic fuse is operated, turn OFF the power supply, and remove

the cause of overcurrent before restarting the power supply for resetting.

●

The electronic fuse is not suitable to use in which the equipment is

operated continuously or daily. Note that operating the equipment con-

tinuously may be unable to satisfy the specifications.

7

FUNCTIONS

●

Trailing edge switching function

•

This function is to accept the input when the reset switch is pressed (con-

tact “close”) and then released (contact “open”) at the manual start setting.

An unexpected start-up due to the welded reset switch can be avoided.

8

MAINTENANCE

●

Be sure to do maintenance before use and 6 month periodic maintenance.

Refer included instruction manual of light curtain for the inspection items.

●

In case replacing this device to new this device, be sure special techni-

cian to exchange it. And do daily maintenance and periodic maintenance.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]