19.1. Cassette Deck Section

·

Measurement Condition

−

−

−

−

Reverse-mode selector switch:

−

−

−

−

Tape edit: NORMAL

−

−

−

−

Make sure head, capstan and press roller are clean.

−

−

−

−

Judgeable room temperature 20 ± 5 °C (68 ± 9°F)

·

Measuring instrument

−

−

−

−

EVM (DC Electronic voltmeter)

−

−

−

−

Digital frequency counter

·

Test Tape

−

−

−

−

Tape speed gain adjustment (3 kHz, -10 dB);

QZZCWAT

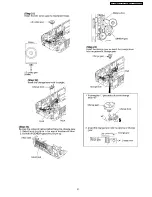

19.1.1. Head Azimuth Adjustment (Deck

1/2)

Caution:

·

Please replace both azimuth adjustment screw and springs

simultaneously when readjusting the head azimuth. (shown

in Fig. 2) Even if you wish to readjust the head azimuth

without replacing the acrews and springs, a fine adjustment

to the azimuth screw and spring.

·

Please remove the screw-locking bond left on the head

base when replacing the azimuth screw.

·

If you wish to readjust the head azimuth, be sure to adjust

with adhering the cassette tape closely to the mechanism

by pushing the center of cassette tape with your finger.

(shown in Fig. 3)

1. Playback the azimuth adjustment portion (8 kHz, -20dB) of

the test tape (QZZCFM) in the forward play mode. Vary the

azimuth adjustment screw until the output of the R-CH (PB

OUT-R) are maximized.

2. Perform the same adjustment in the reverse play mode.

3. After the adjustment, apply screwlock to the azimuth

adjusting screw.

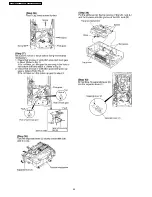

19.1.2. Tape Speed Adjustment (Deck 1/2)

1. Set the tape edit button to “NORMAL” position.

2. Insert the test tape (QZZCWAT) to DECK 2 and playback

(FWD side) the middle portion of it.

3. Adjust Motor VR (DECK 2) for the output value shown

below.

Adjustment target: 2940 ~ 3060 Hz (NORMAL speed)

4. After alignment, assure that the output frequency of the

DECK 1 FWD are within ±60 Hz of the value of the output

frequency of DECK 2 FWD.

Fig. 1

19.1.3. Bias Voltage Check

1. Set the unit “AUX” position.

2. Insert the Normal blank tape (QZZCRA) into DECK 2 and

the unit to “REC” mode (use “

l

REC/STOP” key).

3. Measure and make sure that the output is within the

standard value.

Bias voltage for Deck 2

14±4mV (Normal)

Fig. 2

Fig. 3

19 Measurements and Adjustments

65

SA-VK82DGCP / SA-VK82DGCS / SA-VK82DGS

Summary of Contents for SA-VK82DGCP

Page 11: ...11 Operation Procedures 11 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 12: ...12 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 13: ...12 Disc information 13 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 14: ...14 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 17: ...17 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 39: ...39 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 41: ...41 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 44: ...44 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 45: ...45 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 47: ...47 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 48: ...48 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 49: ...49 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 50: ...50 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 51: ...51 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 52: ...52 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 53: ...53 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 54: ...54 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 55: ...55 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 56: ...56 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 57: ...57 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 127: ...127 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 130: ...130 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 132: ...27 3 Cabinet 27 3 1 Cabinet Parts Location 132 SA VK82DGCP SA VK82DGCS SA VK82DGS ...

Page 133: ...133 SA VK82DGCP SA VK82DGCS SA VK82DGS ...