9 Handling Precautions for Optical Pickup Unit

The laser diode in the optical pickup unit may break down due to static electricity of clothes or human body. Special care must be

taken avoid to electrostatic breakdown when servicing and handling the laser diode.

9.1. Cautions to Be Taken in Handling the Optical Pickup Unit

The laser diode in the optical pickup unit may be damaged due to electrostatic discharge generating from clothes or human body.

Special care must be taken avoid to electrostatic discharge damage when servicing the laser diode.

1. Do not give a considerable shock to the optical pickup unit as it has an extremely high-precise structure.

2. To prevent the laser diode from the electrostatic discharge damage, the flexible cable of the optical pickup unit removed from

the PCB should be short-circuited with a short pin or a clip.

3. The flexible cable may be cut off if an excessive force is applied to it. Use caution when handling the flexible cable.

4. The antistatic FPC is connected to the new optical pickup unit. After replacing the optical pickup unit and connecting the flexible

cable, cut off the antistatic FPC.

9.2. Cautions to Be Taken When Replacing the Optical Pickup

The flexible cable of the optical pickup unit which was supplied as a component is equipped with a short clip to prevent the laser

diode from being damaged due to electrostatic discharge. Remove the short clip before connecting the flexible cable and make

sure that the short land is open. (If the flexible cable is short-circuited, remove the solder.)

9.3. Grounding for electrostatic breakdown prevention

Some devices such as the DVD player use the optical pickup (laser diode) and the optical pickup will be damaged by static

electricity in the working environment. Proceed servicing works under the working environment where grounding works is

completed.

9.3.1. Worktable grounding

1. Put a conductive material (sheet) or iron sheet on the area where the optical pickup is placed, and ground the sheet.

15

SA-HT680PL

Summary of Contents for SA-HT680PL

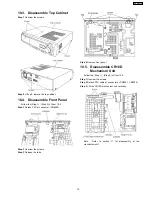

Page 18: ...10 2 Main Components and P C B Locations 18 SA HT680PL ...

Page 23: ...23 SA HT680PL ...

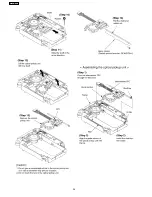

Page 24: ...24 SA HT680PL ...

Page 25: ...11 3 Assembling for traverse motor and spindle motor 25 SA HT680PL ...

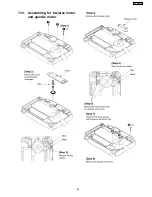

Page 26: ...26 SA HT680PL ...

Page 28: ...28 SA HT680PL ...

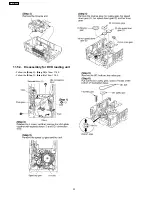

Page 31: ...31 SA HT680PL ...

Page 32: ...32 SA HT680PL ...

Page 34: ...34 SA HT680PL ...

Page 35: ...35 SA HT680PL ...

Page 36: ...36 SA HT680PL ...

Page 37: ...37 SA HT680PL ...

Page 38: ...38 SA HT680PL ...

Page 39: ...39 SA HT680PL ...

Page 40: ...40 SA HT680PL ...

Page 41: ...41 SA HT680PL ...

Page 42: ...42 SA HT680PL ...

Page 43: ...43 SA HT680PL ...

Page 44: ...44 SA HT680PL ...

Page 46: ...46 SA HT680PL ...

Page 52: ...52 SA HT680PL ...

Page 58: ...58 SA HT680PL ...

Page 66: ...SA HT680PL 66 ...

Page 72: ...SA HT680PL 72 ...

Page 88: ...SA HT680PL 88 ...

Page 90: ...SA HT680PL 90 ...

Page 94: ...27 1 Loading Mechanism Traverse Unit Cabinet 94 SA HT680PL ...

Page 95: ...27 1 1 Loading Mechanism Traverse Unit Cabinet Parts Location 95 SA HT680PL ...

Page 96: ...96 SA HT680PL ...

Page 97: ...97 SA HT680PL ...

Page 98: ...98 SA HT680PL ...

Page 99: ...99 SA HT680PL ...

Page 100: ...100 SA HT680PL ...

Page 112: ...27 4 Packaging 112 SA HT680PL ...

Page 113: ...28 Schematic Diagram for printing with letter size 113 SA HT680PL ...

Page 133: ...133 SA HT680PL ...