8. Turn the SCREEN CONTROL on the Flyback Transformer

clockwise carefully and stop at the point where any color is first

observed.

9. In EVR adjustment mode, select the two colors not observed in

step 8 from the following control functions (B CUT -OFF, G CUT -

OFF, or R CUT -OFF) and adjust so that the horizontal line

becomes white.

For example, if the horizontal line appeared red in step 8, select

and adjust the B CUT -OFF and G CUT -OFF.

10. Supply a White Pattern Signal to the Video Input Jack.

11. Press DISPLAY key on the remote control again to return for full

frame scan.

12. Select G DRIVE and B DRIVE in EVR adjustment mode and adjust

so that the entire screen is white.

13. Select SUB BRIGHT in EVR adjustment mode. Then, after making

a note of the original value, adjust to the minimum (C0) and while

turning SUB BRIGHT value from minimum (C0) up to maximum

(3F), confirm that the screen is tracking the White Pattern properly.

Repeat the above steps 5, 9, 11, and 12 until the screen is properly

tracking the White Pattern.

Note:

Before pressing DISPLAY key on the remote control for collapse

scan, select the desired control function and move the shaded area

to the value.

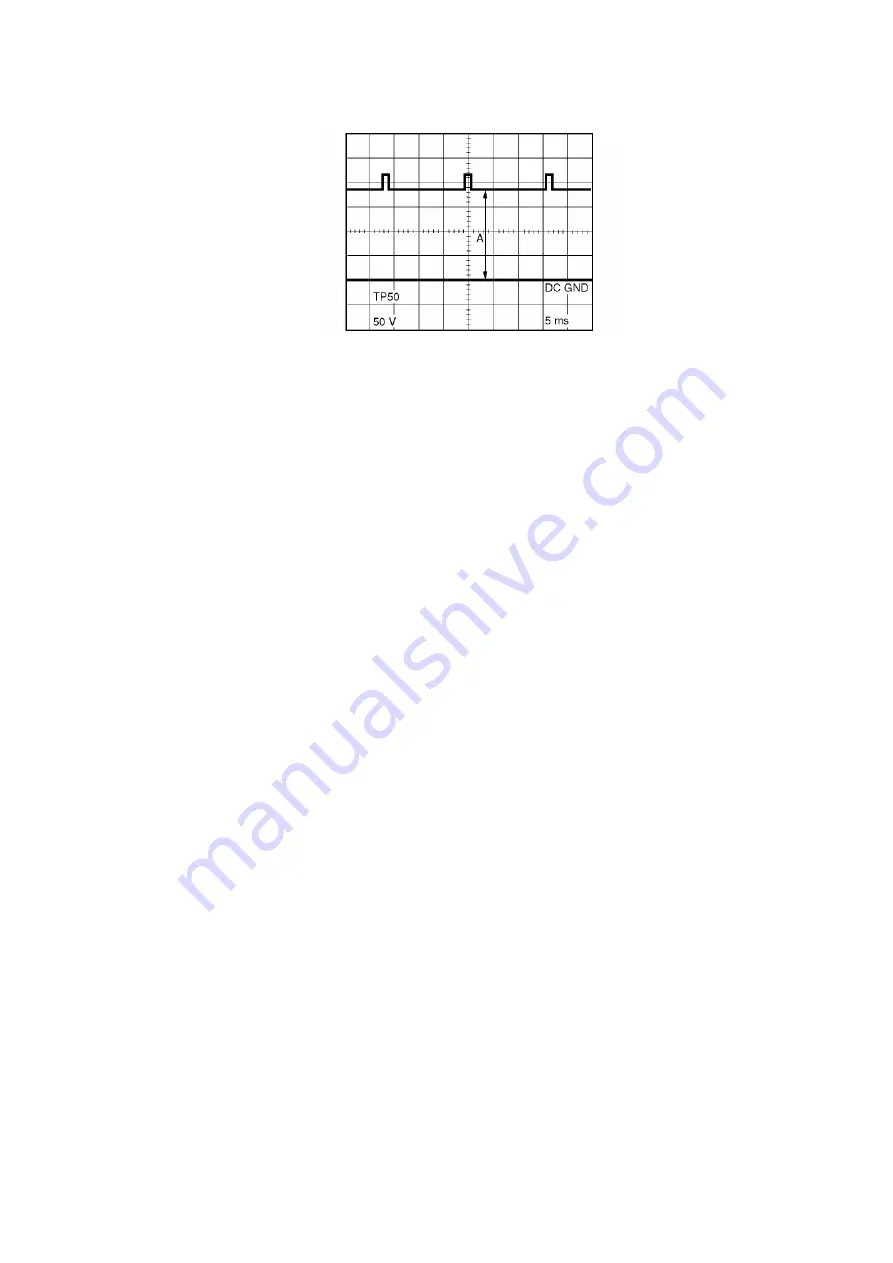

7.3.10. SUB BRIGHTNESS ADJUSTMENT

Purpose:

To set the optimum brightness level.

70

Summary of Contents for OmniVision PV-Q2511

Page 1: ...ORDER NO MKE0102103C1 B6 Combination VCR PVQ 2511 PV C2541 SPECIFICATIONS ...

Page 8: ...Fig 1 3 Fig 1 4 Fig 1 5 8 ...

Page 25: ...Fig D3 Fig D4 25 ...

Page 26: ...Fig D5 6 1 2 1 Notes in chart 26 ...

Page 29: ...6 2 2 Inner Parts Location Fig J1 1 29 ...

Page 30: ...6 2 3 EJECT Position Confirmation Fig J1 2 30 ...

Page 31: ...6 2 4 Grounding Plate Unit Full Erase Head and Cylinder Unit Fig J2 1 31 ...

Page 74: ...11 2 MECHANISM BOTTOM SECTION 74 ...

Page 75: ...11 3 CASSETTE UP COMPARTMENT SECTION 75 ...

Page 76: ...11 4 CHASSIS FRAME SECTION 1 76 ...

Page 77: ...11 5 CHASSIS FRAME SECTION 2 77 ...

Page 78: ...11 6 PACKING PARTS AND ACCESSORIES SECTION 78 ...

Page 102: ...102 ...