39

9.4.

Mechanical Adjustment Procedures

9.4.1.

Adjustment item

9.4.2.

Adjustment procedures

Pay attention, because the adjustment method is different from this machine.

l

Linearlty adjustment & BER value confirmation

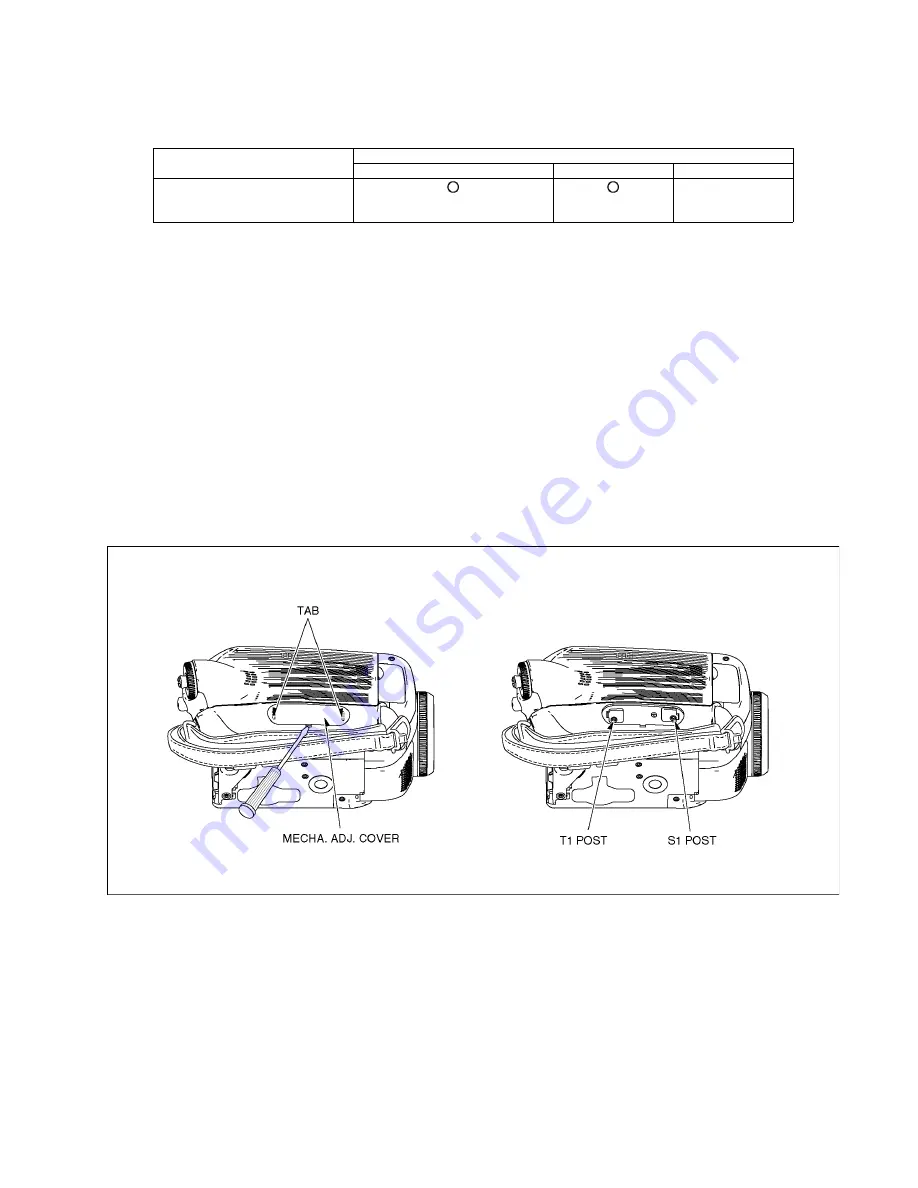

1. Remove the mechanism adjustment cover of this machine as shown in Fig. D1.

2. Remove the front case unit. (Refer to Disassembly Procedures.)

3. The enbelope detection spcial tool board (VFK1641) is connected to this machine as shown in Fig. D2 and D3.

Note:

Be careful not to damage when the Passive Probe is connectied to the connection terminal of Main P.C.B..

It exists the possibility of the damage.

4. The enbelope detection spcial tool board is connected to oscilloscope as shown in Fig. D2 and D3.

Connect the AV Jack of this machine and the oscilloscope by using the Multi cable.

5. The post is adjusted with the post driver(VFK1899) so that recycles the normal tape which recorded NTSC signal and the

detection wave-link become a flat as shown in Fig. D4.

*At the time of the clyinder unit exchange unnecessary.

6. The post is adjusted with the post driver so that recycles a alignment tape(VFM3110EDS) and the detection wave-link

become a flat once again.

7. Recycling the tape that video-taped it wirh this machine after adjustment, the BER value is confirmed withthe item of the BER

the item of the BER confirmation of expert soft inside.

Fig. D1

Item

Adjustment at the time of the part exchange

Half finished goods mechanism

Clyinder

Remarks

Linearlty adjustment

&

BER value confirmation

Summary of Contents for NV-GS300EG

Page 8: ...8 4 Specifications...

Page 10: ...10...

Page 17: ...17 Fig D2 Fig D3 Fig D4 Fig D5...

Page 18: ...18 Fig D6 Fig D7 Fig D8 Fig D9...

Page 19: ...19 Fig D10 Fig D11 Fig D12 Fig D13...

Page 20: ...20 Fig D14 Fig D15 Fig D16...

Page 21: ...21 Fig D17 Fig D18...

Page 22: ...22 Fig D19 Fig D20 Fig D21 Fig D22...

Page 23: ...23 Fig D23 Fig D24 Fig D25 Fig D26...

Page 24: ...24 Fig D27 Fig D28 Fig D29 Fig D30...

Page 25: ...25 Fig D31...

Page 27: ...27 Fig M3...

Page 28: ...28 Fig M4 Fig M5...

Page 29: ...29 Fig M6...

Page 36: ...36 Fig E2 Rough image of set up connection...

Page 40: ...40 Fig D2 Fig D3 Fig D4...

Page 62: ...S 21 2 4 NV GS300 GS308 GS280 Series Front P C B Foil Side 6 4 4 4 4 4 4 4 4 3 3...

Page 80: ...S7 3 LCD Section S 39 202 207 208 209 210 211 201 213 214 212 203 215 205 204 206 B202 B201...