NN-CT867MBPQ NN-CT857WBPQ

2

1 Contents

1 Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Inverter Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 Feature Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

4 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

5 Operation And Digital Programmer Circuit Test Procedure . . . . . . . . . . . . . . . . . . . 5

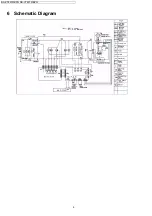

6 Schematic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

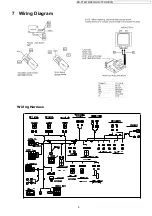

7 Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

8 Description of the Operation Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

9 Cautions to be Observed when Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

10 Part Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11 Component Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

12 Measurements and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

13 Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

14 Description of Operating instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

15 Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

16 Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

17 Door Assy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

18 Escutcheon Base. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

19 Packing and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

20 Trim Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

21 Digital Programmer Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

22 Key Board Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Summary of Contents for NN-CT857WBPQ

Page 4: ...NN CT867MBPQ NN CT857WBPQ 4 4 Control Panel ...

Page 5: ...NN CT867MBPQ NN CT857WBPQ 5 5 Operation And Digital Programmer Circuit Test Procedure ...

Page 6: ...NN CT867MBPQ NN CT857WBPQ 6 ...

Page 7: ...NN CT867MBPQ NN CT857WBPQ 7 ...

Page 8: ...NN CT867MBPQ NN CT857WBPQ 8 6 Schematic Diagram ...

Page 9: ...NN CT867MBPQ NN CT857WBPQ 9 7 Wiring Diagram Wiring Harness ...

Page 13: ...NN CT867MBPQ NN CT857WBPQ 13 8 5 1 convection and microwave duty cycles Figure 1 ...

Page 14: ...NN CT867MBPQ NN CT857WBPQ 14 8 5 2 grill and microwave duty cycles Figure 2 ...

Page 15: ...NN CT867MBPQ NN CT857WBPQ 15 Figure 3 8 5 3 Grill Convection and microwave duty cycles ...

Page 28: ...NN CT867MBPQ NN CT857WBPQ 28 Removing the circulation motor Figure 16 ...

Page 32: ...NN CT867MBPQ NN CT857WBPQ 32 13 Troubleshooting Guide ...