-

E11

-

-

E10

-

English

Environmental condition

Item

Condition

Ambient temperature

–10 ℃ to 40 ℃ (free from freezing)

*1

Ambient humidity

20% to 85% RH (free from condensation)

Storage temperature

At normal temperature and normal humidity

*2

Protection structure

IP65 (Excluding shaft pass-through section and lead wire connector)

*3

Vibration

Not greater than 4.9 m/s

2

(10 to 60 Hz)

Altitude

Not greater than 1000 m

*1 Ambient temperature is measured at a distance of 5 cm from the motor.

*2 Temperature which is acceptable for a short time, such as during transportation, is –20 ℃ to

60 ℃ (free from freezing).

*3 This motor meets test requirements specified in EN standards (EN60529 and EN60034-5).

This motor cannot be used for an application that requires long term waterproof performance,

such as the case where the motor is always washed with water.

Installation of brushless motor

Oil and water protection

1) Direct down the lead of cable as far as possible.

2) Avoid use in such an environment where the motor is always exposed to oil and water.

3) Avoid use with cable immersed in oil or water.

Stress to cable

1) Make sure that stress is not applied to the lead or connection of cable due to bending or

dead weight.

2) In installation where the motor moves, fix the cable of motor, and house the extension

cable connected to it in the cable bear to reduce stress by bending as small as possible.

3) Allow the bending radius of cable as large as possible.

Output shaft permissible load

1) The mechanical system should be so designed that the permissible radial load and

thrust load specified for a specific model will be supported by the shaft during installation

and operation.

2) When using rigid coupling, avoid application of unnecessary load. Excessive bending

load will cause breaking of shaft or shortening of bearing life.

3) Use a high rigid but flexible coupling so that the radial load due to minute misalignment

is limited below the allowable value.

Installation guidelines

1) When installing a coupling to or removing a coupling from the motor shaft end, do not

apply shock directly to the shaft with e.g. a hammer.

2) Make an exact centering (incomplete alignment may cause vibration and damage the

bearing).

3) Do not allow operation that will cause the frame surface temperature to rise to 80 ℃ or

higher (ambient temperature at 40 ℃).

・

Geared shaft motor should be used with the gear head attached to it.

・

Round shaft motor should be used with its heat dissipated to the machine and equipment.

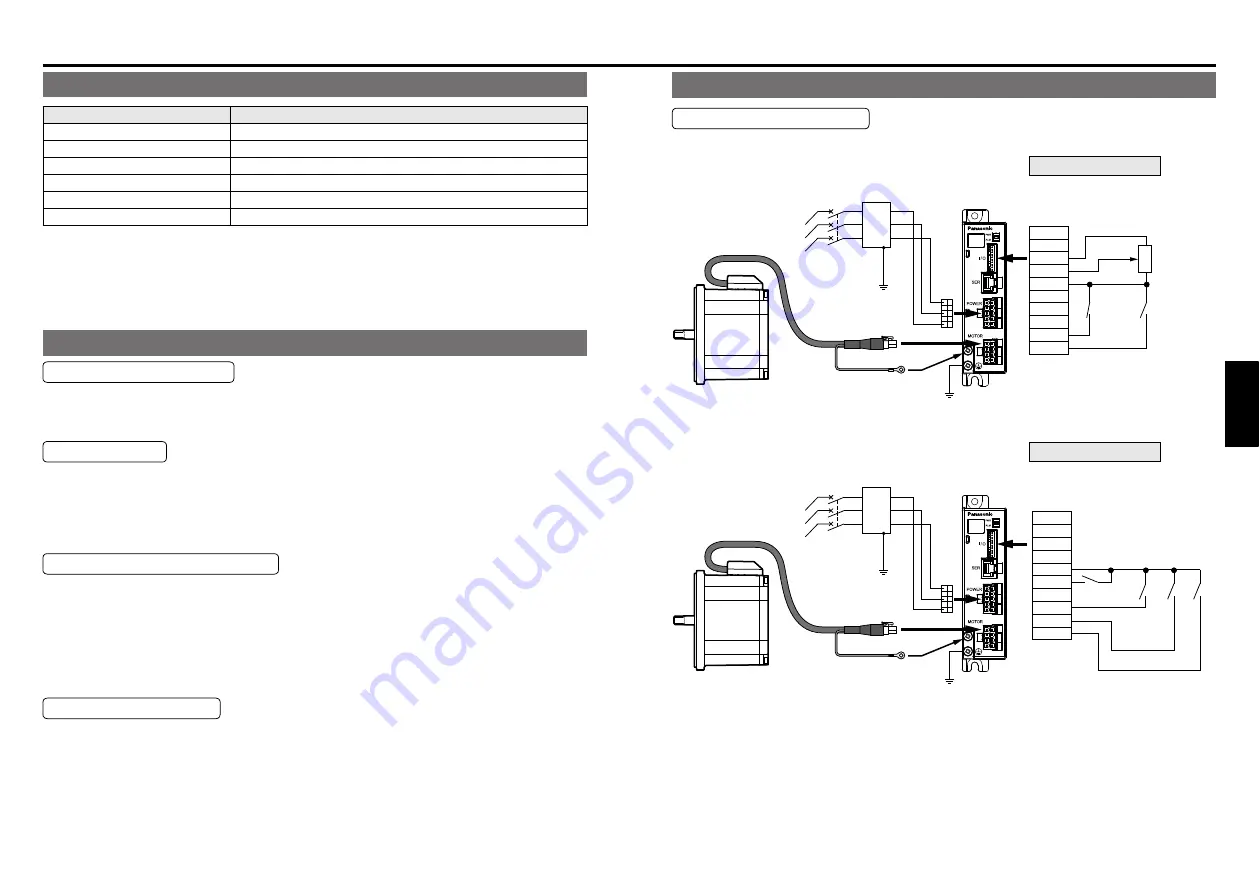

Installation

Wiring

02

Connector

for control

signals (I/O)

External speed setting

Variable resister 5 kΩ

B characteristic 1/4 W

Brushless

amplifier

change of

Direction

10

1

01

+

5V

FIN

GND

I

3

I

4

I

5

I

2

I

1

Power

supply

input

L1

L2

L3

1

5

6

10

Be sure to ground the grounding terminal.

MCCB

Molded Case

(

Circuit Breaker

)

Grounding

Noise

filter

Brushless

amplifier

Power

supply

input

L1

L2

L3

1

5

6

10

Be sure to ground the grounding terminal.

MCCB

Molded Case

(

Circuit Breaker

)

Grounding

Noise

filter

Run/Stop

command

In wiring to power supply (outside of equipment) from MCCB, use an electric wire of 1.6 mm

diameter (2.0 mm

2

) or more both for main circuit and grounding.

Apply grounding class D (100 Ω or below) for grounding.

Do not tighten the ground wires together, but connect them individually.

Fastening torque of earth screws to be 0.49 to 0.98 N·m.

GV series

Forced trip

02

Connector

for control

signals (I/O)

10

1

01

+

5V

(

NC

)

GND

I

3

(

NC

)

I

4

I

2

I

1

• In Case of 3-Phase 200 V

GP series

Run start

Point designation

Home sensor

Wiring

Standard wiring diagram