52

10.3.2.

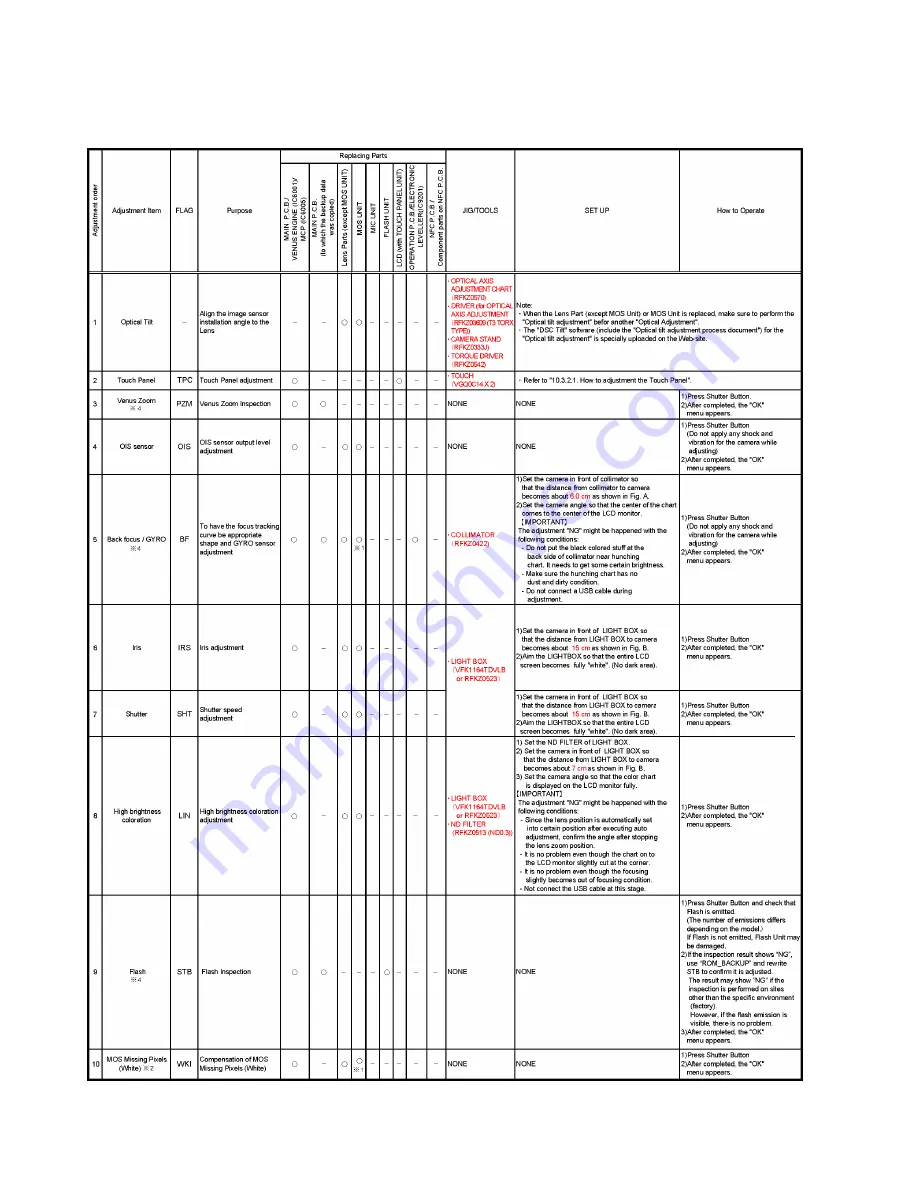

Adjustment Specifications

The following matrix table shows the relation between the replaced part and the Necessary Adjustment.

When a part is replaced, make sure to perform the necessary adjustment(s) in the order indicated.

The table below shows all the information necessary to perform each adjustment.

Summary of Contents for Lumix DMC-TZ37EC

Page 28: ...28 9 Disassembly and Assembly Instructions 9 1 Disassembly Flow Chart 9 2 P C B Location ...

Page 32: ...32 9 3 3 Removal of the LCD Unit Fig D3 9 3 4 Removal of the Frame Plate Unit Fig D4 ...

Page 33: ...33 9 3 5 Removal of the Lens Unit Fig D5 9 3 6 Removal of the Main P C B Fig D6 ...

Page 34: ...34 9 3 7 Removal of the NFC P C B Fig D7 9 3 8 Removal of the Front Case Unit Fig D8 ...

Page 35: ...35 9 3 9 Removal of the Top Case Unit Fig D9 9 3 10 Removal of the Top P C B Fig D10 ...

Page 58: ...58 ...