INSTRUCTION MANUAL

Collimated Beam Sensor

LA-A1 / LA-A1P

CMJE-LAA1 (06)No.0042-36V

Thank you very much for purchasing Panasonic products. Read this Instruction Man-

ual carefully and thoroughly for the correct and optimum use of this product. Kindly

keep this manual in a convenient place for quick reference.

WARNING

Never use this product as a device for personnel protection.

In case of using devices for personnel protection, use products which

meet laws and standards, such as OSHA, ANSI or IEC etc., for personnel

protection applicable in each region or country.

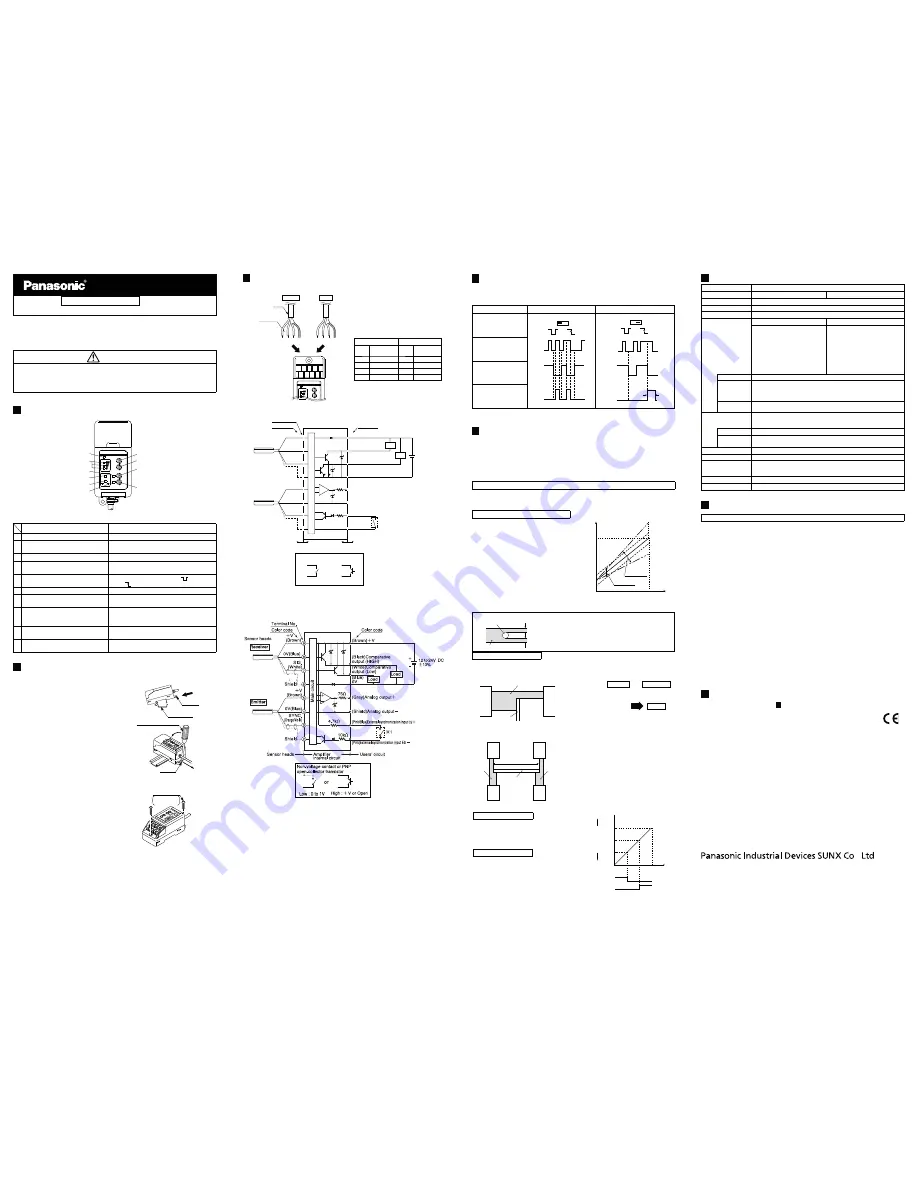

1

FUNCTION DESCRIPTION

POWER

STB

SPAN

SHIFT

ES

HIGH

LOW

LA-A1

1

2

3

4

5

6

7

10

8

9

Description

Function

1 Power indicator (Green

㧕

Lights up when the power is supplied.

2 Stability indicators(Green×3)

Light up in three steps in proportion to the

intensity of received

beam.

3 HIGH operation indicator(Orange)

Lights up when HIGH output is ON.

4

External synchronization

indicator (Green)

Lights up when the external synchronization

input is LOW.(Active-LOW)

5

External synchronization

selection switch

Selects between gate trigger(

) / or edge

trigger(

)

6 LOW operation indicator(Orange)

Lights up when LOW output is ON.

7 Span adjuster

15-turn adjuster sets the span for the analog

output voltage.

8 Shift adjuster

15-turn adjuster sets the offset for the analog

output voltage. It calibrates the output

voltage at zero input.

9 HIGH level adjuster

15-turn adjuster sets the HIGH output

threshold level.(Over-dark level).

10 LOW level adjuster

15-turn adjuster sets the LOW output

threshold level.(Under-dark level).

2

MOUNTING

Mounting on DIN rail

1.

Make sure the mounting stopper is

latched inside. Hook the front side

of the controller on the 35mm width

DIN rail at the bottom.

2.

Snap the controller down on the

35mm width DIN rail.

* -

driver into the mounting stopper

and pull out.

Stopper

1

35mm width

DIN rail

2

Flathead screwdriver

Stopper

Mounting with screws

Use two M4 screws that are com-

mercially

available. The tightening

torque should be 1.2N

㨯

m or less.

M4 pan head

screws

Please arrange

separately.

3

CONNECTION

Wiring diagram

Receiver

Emitter

Cable

Color code

Lower terminal block

for the emitter

Upper terminal block

for the receiver

Brown

White

Blue

Shield

Brown

Blue

Shield

STB

SPAN

SHIFT

1

2

3

4

5

6

7

8

9

POWER

LA-A1

6

7

8

9

2

3

4

5

Orange / V

iolet

Connect color-coded wires in accordance

with the table below.The receiver wires

should be connected on the upper terminal

block and the emitter wires on the lower ter-

minal block.

'OKVVGT

4GEGKXGT

Terminal

No.

Color code

Terminal

No.

Color code

2

5JKGNF

6

5JKGNF

3

Orange / Violet

7

9JKVG

4

$NWG

8

$NWG

5

$TQYP

9

$TQYP

Note: Do not connect any wire to the terminal No.1

I/O circuit diagram

㧨

LA-A1

NPN

㧪

100mA max.

100mA max.

75

ǡ

9

8

7

6

5

4

3

2

Terminal No.

Color code

Color code

s

Receiver

Emitter

(Brown) +V

(Gray) Analog

(Pink) External synchronization input ES +

(Pink / Blue) External synchronization input ES

(Shield) Analog output

(Blue) 0V

0V (Blue)

0V (Blue)

SYNC.

Shield

Shield

Main circuit

㧗

㧙

Load

Load +

*1

Users' circuit

Amplifier internal

circuit

Sensor heads

Non-voltage contact or

NPN open-collector transistor

Low: 0 to 1V

High: +V or Open

or

*1

I/O circuit diagram

㧨

LA-A1P

PNP

㧪

*1

Note

1):

㧨

NPN

㧪

When ES + (pink) and ES - (pink / blue) are connected, both HIGH and LOW

comparative outputs are triggered in the mode selected by the external synchronization

selection switch.

2):

㧨

PNP

㧪

When ES (pink/blue) and ES (pink) are connected, both HIGH and

LOWcomparative outputs are triggered in the mode selected by the external synchronization

selection switch.

3):To disable external synchronization, set the external synchronization selection switch on

'Gate trigger' and short-circuit the external synchronization inputs (ES + and ES -).

! " # "" $#& " ; <

more and connect the shield wire of the along output to 0V (common input) of the device.

5):Insulate all unused wires individually to avoid mis-contact.

4

EXTERNAL SYNCHRONIZATION FUNCTION

The external synchronization input controls the timing or the effective

duration of the two comparative outputs. Either, edge, or, gate trigger is

selectable.

Gate trigger

Edge trigger

External synchronization

selection switch

ON

OFF

High

Low

ON

OFF

ON

OFF

High

Low

ON

OFF

Aprox

40ms

Sensing signal

External synchronization

input

Comparative outputs

㧔

HIGH,LOW

㧕

External synchronization input signal : LOW ... 0 to 1V, High ...+V or Open

Note: To disable external synchronization, set the external synchronization selection switch on 'Gate trigger' and short-

circuit the external synchronization inputs (ES+ and ES -).

5

ALIGNMENT

Beam alignment of sensor heads

Make sure that, at least, one stability indicator lights up when you supply

LA-305

sensor heads. While aligning sensor

heads, the more stability indicators light up, the more reliable detection can be

obtained.

If either sensor head moves out of position, do all adjustments, including beam

alignment, from the beginning.

Refer to the instruction manual of

LA-305

for more details of beam alignment of sensor heads

Calibrating analog output

The analog voltage output relates to the span and the shift adjustments as in

How to calibrate the output into 1 to 5V

1.

Block the whole beam to enter into the

darkest condition and set the output at

1V with the shift adjuster.

2.

Allow the whole beam to be received to

enter into the lightest condition and set

the output at 5V with the span adjuster.

3.

For more accurate calibration, repeat

1

and

2

.

5V

1V

Span

adjustment

Shift

adjustment

Darkest

condition

Lightest

condition

Incident

beam

intensity

Analog output

㧨

Explanation

㧪

(e.g.) Wire detection

A

Wire

Collimated beam

B

C

Incident beam width = A + C

Interrupted beam width = B

Lightest condition: The entire beam is received.

Darkest condition: The entire beam is blocked.

Further use of shift adjuster

If you want to change the output voltage value after the calibration, the shift

adjuster enables you to shift the analog voltage up or down within about ±0.5V.

(e.g.) To shift the analog voltage from 2.51V to 3V with a certain amount of beam blockage

ޕ

Collimated beam

Sensing object

Emitter

Receiver

Darkest condition

Setting condition

Lightest condition

Previous

1V

to

2.51V

to

5V

Subsequent

1.49V

to

3V

to

5.49V

(Application) When two sensor heads are used for width measurement the shift adjuster can

eliminate the need to move the sensor heads during set-up.

Reference width

Collimated

beam

Collimated

beam

Sensing object

Emitter

Receiver

Emitter

Receiver

Up to now, the sensor heads have had to be located

at the exact positions with respect to the reference

object to measure at the criterion of 3V, center of 1

to 5V. However, even a simulated center is easily

obtained by the shift adjustment, without any

realignment

.

Note: To make the whole beam balanced between the lightest

and darkest conditions, the sensor heads should be posi-

tioned where the sensor generates 3V with the beam half

blocked.

Adjusting HIGH & LOW output levels (Two independent outputs)

HIGH output threshold level

Block as much of the beam for which you want

the HIGH output. Turn the HIGH adjuster to just

before the point where the HIGH operation indi-

cator lights up. The threshold level increases as

the adjuster is turned clockwise.

LOW output threshold level

Again, block as little of the beam for which you

want the LOW output. Turn the LOW adjuster to

just before the point where the LOW operation

indicator lights up. The threshold level increases

as the adjuster is turned clockwise.

$?!@QYZQ[\]#^_

LOW

output

level

HIGH

output

level

ON

OFF

ON

OFF

Darkest

condition

Lightest

condition

Incident

beam

intensity

Comparative

output (HIGH)

Comparative

output (LOW)

High

Low

Analog voltage

6

MAJOR SPECIFICATIONS

Designation

`^

㨯

Model No.

LA-A1

LA-A1P

Applicable sensor head

LA305

㧔

Note

)

Supply voltage

12 to 24V DC±10% Ripple P-P 10% or less

Current consumption

120mA or less (including sensor heads)

Comparative outputs

(HIGH,LOW)

NPN open-collector transistor

PNP open-collector transistor

・

Maximum sink current: 100mA

・

Applied voltage: 30V DC or less

(between comparative output

and 0V)

・

Residual voltage: 1.5V or less

(at 100mA sink cur-

rent)

0.5V or less

(at 16mA sink cur-

rent)

・

Maximum sink current: 100mA

・

Applied voltage: 30V DC or less

・

Residual voltage: 1.5V or less

(at 100mA source cur-

rent)

0.5V or less

(at 16mA source cur-

rent)

Response time

0.5ms or less

Output

operation

HIGH OUT: ON when the received beam level is equal or lower than

Over-dark level

LOW OUT: ON when the received beam level is equal or higher than

Under-dark level

Short-circuit

protection

Incorporated

Analog output

Analog voltage

・

Output voltage: 1V (Darkest) to 5V (Lightest)

・

\""!

Slew rate

8V/ms or more

Temperature

characteristics

0.05%F.S./

͠

or less

Ambient temperature

0 to +50

͠

(No dew condensation), Storage: -20 to +70

͠

Ambient humidity

35 to 85% RH, Storage: 35 to 85% RH

Material

Enclosure: Heat-resistant ABS, Terminal cover: Heat-resistant

ABS

Front cover: Polycarbonate

Cable

0.22mm

2

(Shield wire:0.15mm

2

) 7-core composite cabtyre, 2m long

Accessory

Adjusting screwdriver: 1 pc.

Note: Refer to the instruction manual of LA-305 for more details.

7

CAUTIONS

Make sure to use the exclusive sensor head

LA-305

&#_

This product has been developed / produced for industrial use only.

Make sure that the power supply is off while wiring.

Take care that wrong wiring will damage the sensor.

Verify that the supply voltage variation is within the rating.

If power is supplied from a commercial switching regulator, ensure that the

frame ground (F.G.) terminal of the power supply is connected to an actual

ground.

In case noise generating equipment (switching regulator, inverter motor,

etc.) is used in the vicinity of this product, connect the frame ground (F.G.)

terminal of the equipment to an actual ground.

Do not run the wires together with high-voltage lines or power lines or put

them in the same raceway. This can cause malfunction due to induction.

Extension up to total 50m, or less, is possible with 0.22mm

2

, or more,cable.

Use a shielded cable for extension of the analog output cable.

In case of using this product as a CE marking conformity product, cable

extension of the power wire and I/O wire must be wthin 30m.

! " #

the output until stabilized.

Make sure that stress by forcible bend or pulling is not applied directly to the

sensor cable joint.

This sensor is suitable for indoor use only.

Do not use this sensor in places having excessive vapor, dust, etc., or where it

may come in direct contact with water, or corrosive gas

Take care that the sensor does not come in direct contact with water, oil,

grease, organic solvents, such as, thinner etc., strong acid or alkaline.

Make sure to mount the terminal cover

8

INTENDED PRODUCTS FOR CE MARKING

The models listed under “

6

MAJOR SPECIFICATIONS

” come with

CE Marking. As for all other models, please contact us.

Contact for CE

Panasonic Marketing Europe GmbH Panasonic Testing Center

Winsbergring 15, 22525 Hamburg,Germany

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]