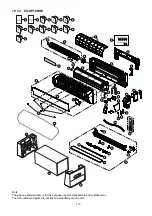

122

SAFETY REF. NO.

PART NAME & DESCRIPTION

QTY.

CU-UE9RKE

CU-UE12RKE

REMARK

1

CHASSIS ASSY

1

CWD50K2073

←

2

SOUND PROOF MATERIAL

1

CWG302314

←

3

FAN MOTOR BRACKET

1

CWD541089

←

4

SCREW - FAN MOTOR BRACKET

2

CWH551217

←

5

FAN MOTOR

1

ARS6411AC

←

O

6

SCREW - FAN MOTOR MOUNT

4

CWH55252J

←

7

PROPELLER FAN ASSY

1

CWH03K1010

←

8

NUT - PROPELLER FAN

1

CWH56053J

←

9

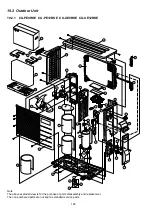

COMPRESSOR

1

5RS092XCD21

5RS102XBC21

O

10

ANTI - VIBRATION BUSHING

3

CWH50077

←

11

NUT - COMPRESSOR MOUNT

3

CWH561096

←

12

CONDENSER

1

CWB32C2985

CWB32C2448

13

TUBE ASS’Y (CAP. & CHECK VALVE)

1

CWT01C7081

CWT01C7082

O

14

DISCHARGE MUFFLER (4-WAY VALVE)

1

CWB121010

←

O

15

HOLDER COUPLING

1

CWH351233

←

16

2-WAYS VALVE (LIQUID)

1

CWB021559

CWB021457

O

17

3-WAY VALVE (GAS)

1

CWB011374

←

O

19

REACTOR

1

G0C103J00013

←

O

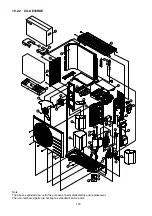

20

TERMINAL COVER

1

CWH171039A

←

21

NUT - TERMINAL COVER

1

CWH7080300J

←

22

SOUND PROOF BOARD

1

CWH151172

←

23A

SOUND PROOF MATERIAL

1

CWG302948

←

23B

SOUND PROOF MATERIAL

1

CWG302316

←

23C

SOUND PROOF MATERIAL

1

CWG302317

←

24

SENSOR CO - COMP TEMP

1

CWA50C2632

←

O

25

CONTROL BOARD COVER - TOP

1

CWH131264

←

26

ELECTRONIC CONTROLLER - MAIN

1

CWA73C9001R

CWA73C9002R

O

27

TERMINAL BOARD ASSY

1

CWA28K1036J

←

O

28

CABINET SIDE PLATE CO. (RIGHT)

1

CWE04C1512

←

29

SENSOR CO - AIR TEMP AND PIPE TEMP

1

CWA50C2767

←

O

30

CABINET SIDE PLATE

1

CWE041031A

←

31

CABINET FRONT PLATE CO.

1

CWE06C1039

CWE06C1136

32

CABINET TOP PLATE

1

CWE031014A

←

33

PLATE - C. B. COVER TERMINAL

1

CWH131301

←

34

CONTROL BOARD COVER CO.

1

CWH13C1211

←

35

HANDLE

1

CWE161010

←

38

4-WAYS VALVE

1

CWB001063

←

O

39

V-COIL COMPLETE (4-WAY VALVE)

1

CWA43C2431

←

O

42

FLEXIBLE PIPE (L-TUBE)

1

CWH5850080

←

43

PACKING - L.TUBE

1

CWB81012

←

50

ACCESSORY CO. (DRAIN ELBOW)

1

CWG87C900

←

51

BAG

1

CWG861078

←

52

BASE BOARD - COMPLETE

1

CWG62C1095

←

53

SHOCK ABSORBER (RIGHT)

1

CWG712969

←

54

SHOCK ABSORBER (LEFT)

1

CWG712970

←

55

C.C.CASE

1

CWG568356

←

(Note)

All parts are supplied from PAPAMY, Malaysia (Vendor Code: 00029488).

“O” marked parts are recommended to be kept in stock.